Leroy Cronin

Achieving Operational Universality through a Turing Complete Chemputer

Feb 05, 2025Abstract:The most fundamental abstraction underlying all modern computers is the Turing Machine, that is if any modern computer can simulate a Turing Machine, an equivalence which is called Turing completeness, it is theoretically possible to achieve any task that can be algorithmically described by executing a series of discrete unit operations. In chemistry, the ability to program chemical processes is demanding because it is hard to ensure that the process can be understood at a high level of abstraction, and then reduced to practice. Herein we exploit the concept of Turing completeness applied to robotic platforms for chemistry that can be used to synthesise complex molecules through unit operations that execute chemical processes using a chemically-aware programming language, XDL. We leverage the concept of computability by computers to synthesizability of chemical compounds by automated synthesis machines. The results of an interactive demonstration of Turing completeness using the colour gamut and conditional logic are presented and examples of chemical use-cases are discussed. Over 16.7 million combinations of Red, Green, Blue (RGB) colour space were binned into 5 discrete values and measured over 10 regions of interest (ROIs), affording 78 million possible states per step and served as a proxy for conceptual, chemical space exploration. This formal description establishes a formal framework in future chemical programming languages to ensure complex logic operations are expressed and executed correctly, with the possibility of error correction, in the automated and autonomous pursuit of increasingly complex molecules.

Validation of the Scientific Literature via Chemputation Augmented by Large Language Models

Oct 08, 2024Abstract:Chemputation is the process of programming chemical robots to do experiments using a universal symbolic language, but the literature can be error prone and hard to read due to ambiguities. Large Language Models (LLMs) have demonstrated remarkable capabilities in various domains, including natural language processing, robotic control, and more recently, chemistry. Despite significant advancements in standardizing the reporting and collection of synthetic chemistry data, the automatic reproduction of reported syntheses remains a labour-intensive task. In this work, we introduce an LLM-based chemical research agent workflow designed for the automatic validation of synthetic literature procedures. Our workflow can autonomously extract synthetic procedures and analytical data from extensive documents, translate these procedures into universal XDL code, simulate the execution of the procedure in a hardware-specific setup, and ultimately execute the procedure on an XDL-controlled robotic system for synthetic chemistry. This demonstrates the potential of LLM-based workflows for autonomous chemical synthesis with Chemputers. Due to the abstraction of XDL this approach is safe, secure, and scalable since hallucinations will not be chemputable and the XDL can be both verified and encrypted. Unlike previous efforts, which either addressed only a limited portion of the workflow, relied on inflexible hard-coded rules, or lacked validation in physical systems, our approach provides four realistic examples of syntheses directly executed from synthetic literature. We anticipate that our workflow will significantly enhance automation in robotically driven synthetic chemistry research, streamline data extraction, improve the reproducibility, scalability, and safety of synthetic and experimental chemistry.

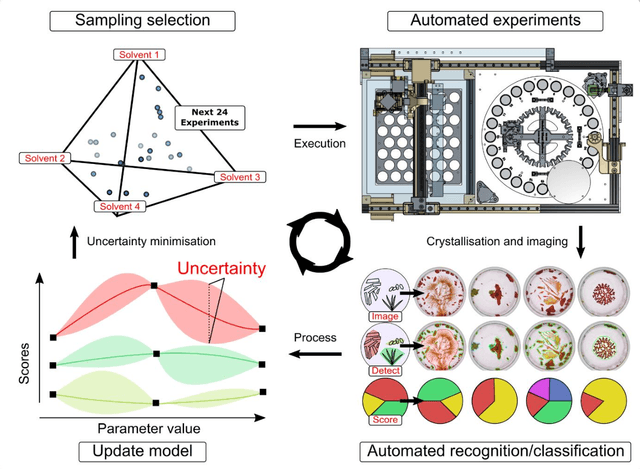

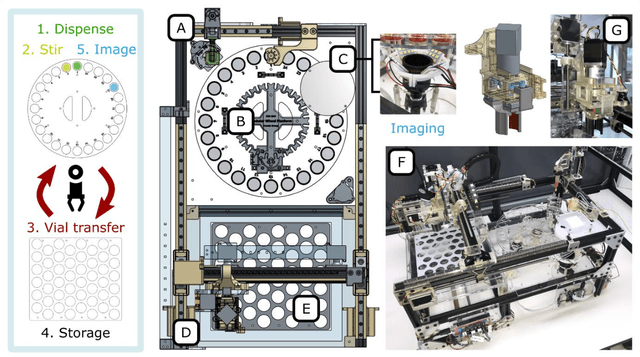

AI-Driven Robotic Crystal Explorer for Rapid Polymorph Identification

Sep 08, 2024

Abstract:Crystallisation is an important phenomenon which facilitates the purification as well as structural and bulk phase material characterisation using crystallographic methods. However, different conditions can lead to a vast set of different crystal structure polymorphs and these often exhibit different physical properties, allowing materials to be tailored to specific purposes. This means the high dimensionality that can result from variations in the conditions which affect crystallisation, and the interaction between them, means that exhaustive exploration is difficult, time-consuming, and costly to explore. Herein we present a robotic crystal search engine for the automated and efficient high-throughput approach to the exploration of crystallisation conditions. The system comprises a closed-loop computer crystal-vision system that uses machine learning to both identify crystals and classify their identity in a multiplexed robotic platform. By exploring the formation of a well-known polymorph, we were able to show how a robotic system could be used to efficiently search experimental space as a function of relative polymorph amount and efficiently create a high dimensionality phase diagram with minimal experimental budget and without expensive analytical techniques such as crystallography. In this way, we identify the set of polymorphs possible within a set of experimental conditions, as well as the optimal values of these conditions to grow each polymorph.

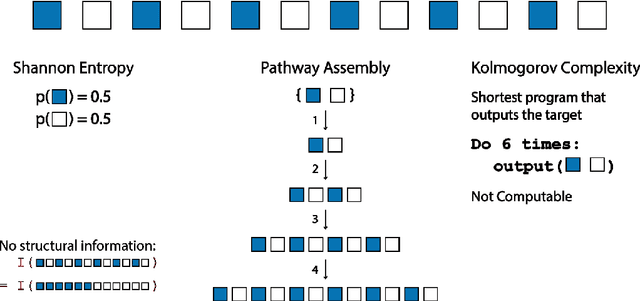

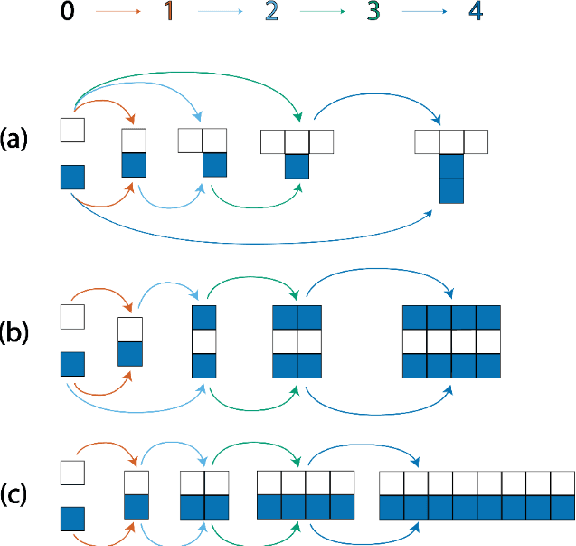

Quantifying the pathways to life using assembly spaces

Aug 09, 2019

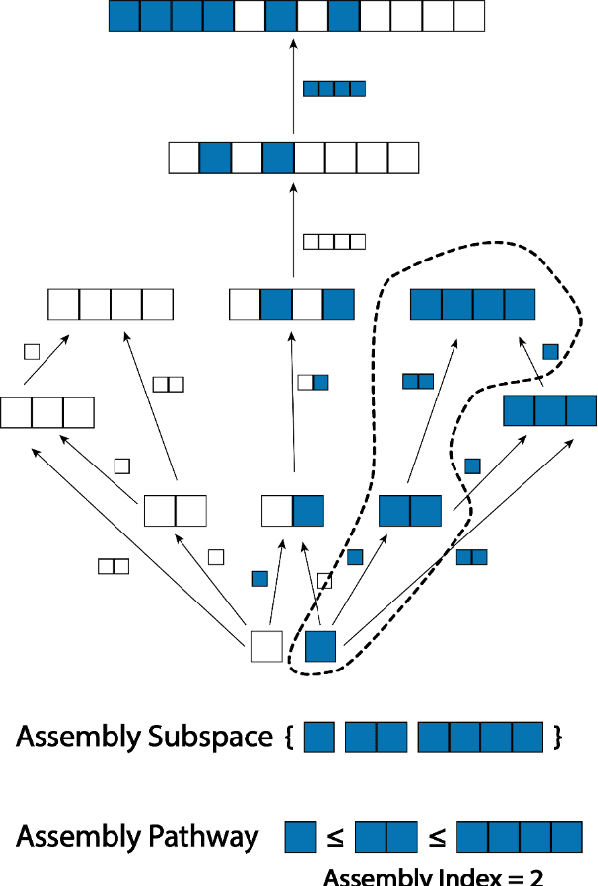

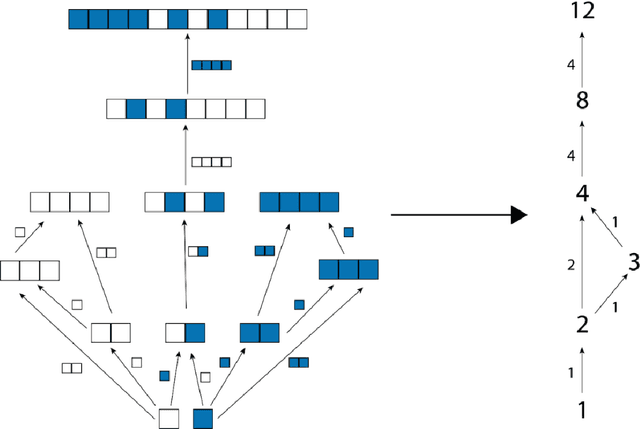

Abstract:We have developed the concept of pathway assembly to explore the amount of extrinsic information required to build an object. To quantify this information in an agnostic way, we present a method to determine the amount of pathway assembly information contained within such an object by deconstructing the object into its irreducible parts, and then evaluating the minimum number of steps to reconstruct the object along any pathway. The mathematical formalisation of this approach uses an assembly space. By finding the minimal number of steps contained in the route by which the objects can be assembled within that space, we can compare how much information (I) is gained from knowing this pathway assembly index (PA) according to I_PA=log (|N|)/(|N_PA |) where, for an end product with PA=x, N is the set of objects possible that can be created from the same irreducible parts within x steps regardless of PA, and NPA is the subset of those objects with the precise pathway assembly index PA=x. Applying this formalism to objects formed in 1D, 2D and 3D space allows us to identify objects in the world or wider Universe that have high assembly numbers. We propose that objects with PA greater than a threshold are important because these are uniquely identifiable as those that must have been produced by biological or technological processes, rather than the assembly occurring via unbiased random processes alone. We think this approach is needed to help identify the new physical and chemical laws needed to understand what life is, by quantifying what life does.

Exploration of Self-Propelling Droplets Using a Curiosity Driven Robotic Assistant

Apr 22, 2019

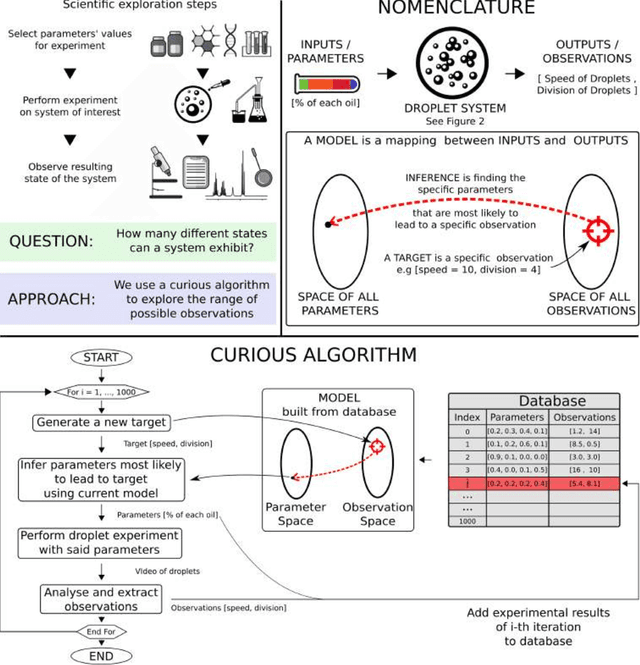

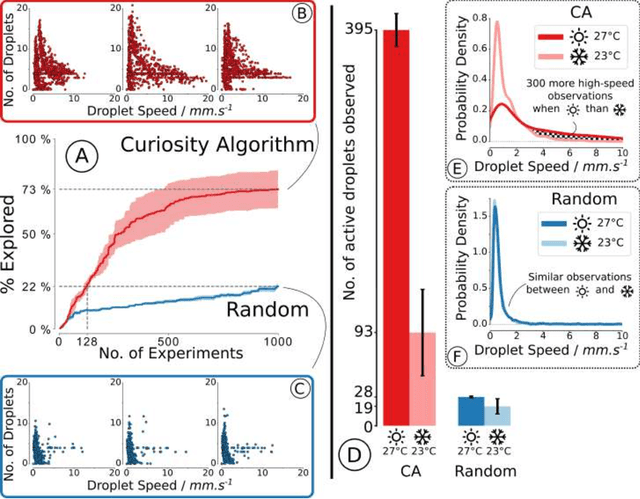

Abstract:We describe a chemical robotic assistant equipped with a curiosity algorithm (CA) that can efficiently explore the state a complex chemical system can exhibit. The CA-robot is designed to explore formulations in an open-ended way with no explicit optimization target. By applying the CA-robot to the study of self-propelling multicomponent oil-in-water droplets, we are able to observe an order of magnitude more variety of droplet behaviours than possible with a random parameter search and given the same budget. We demonstrate that the CA-robot enabled the discovery of a sudden and highly specific response of droplets to slight temperature changes. Six modes of self-propelled droplets motion were identified and classified using a time-temperature phase diagram and probed using a variety of techniques including NMR. This work illustrates how target free search can significantly increase the rate of unpredictable observations leading to new discoveries with potential applications in formulation chemistry.

Hardware and Software manual for Evolution of Oil Droplets in a Chemo-Robotic Platform

Nov 07, 2014

Abstract:This manual outlines a fully automated liquid handling robot to enable physically-embodied evolution within a chemical oil-droplet system. The robot is based upon the REPRAP3D printer system and makes the droplets by mixing chemicals and then placing them in a petri dish after which they are recorded using a camera and the behaviour of the droplets analysed using image recognition software. This manual accompanies the open access publication published in Nature Communications DOI: 10.1038/ncomms6571.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge