Ksenia Antipova

Making the black-box brighter: interpreting machine learning algorithm for forecasting drilling accidents

Sep 06, 2022

Abstract:We present an approach for interpreting a black-box alarming system for forecasting accidents and anomalies during the drilling of oil and gas wells. The interpretation methodology aims to explain the local behavior of the accident predictive model to drilling engineers. The explanatory model uses Shapley additive explanations analysis of features, obtained through Bag-of-features representation of telemetry logs used during the drilling accident forecasting phase. Validation shows that the explanatory model has 15% precision at 70% recall, and overcomes the metric values of a random baseline and multi-head attention neural network. These results justify that the developed explanatory model is better aligned with explanations of drilling engineers, than the state-of-the-art method. The joint performance of explanatory and Bag-of-features models allows drilling engineers to understand the logic behind the system decisions at the particular moment, pay attention to highlighted telemetry regions, and correspondingly, increase the trust level in the accident forecasting alarms.

Forecasting the abnormal events at well drilling with machine learning

Mar 10, 2022

Abstract:We present a data-driven and physics-informed algorithm for drilling accident forecasting. The core machine-learning algorithm uses the data from the drilling telemetry representing the time-series. We have developed a Bag-of-features representation of the time series that enables the algorithm to predict the probabilities of six types of drilling accidents in real-time. The machine-learning model is trained on the 125 past drilling accidents from 100 different Russian oil and gas wells. Validation shows that the model can forecast 70% of drilling accidents with a false positive rate equals to 40%. The model addresses partial prevention of the drilling accidents at the well construction.

Failures detection at directional drilling using real-time analogues search

Jun 06, 2019

Abstract:One of the main challenges in the construction of oil and gas wells is the need to detect and avoid abnormal situations, which can lead to accidents. Accidents have some indicators that help to find them during the drilling process. In this article, we present a data-driven model trained on historical data from drilling accidents that can detect different types of accidents using real-time signals. The results show that using the time-series comparison, based on aggregated statistics and gradient boosting classification, it is possible to detect an anomaly and identify its type by comparing current measurements while drilling with the stored ones from the database of accidents.

Real-time data-driven detection of the rock type alteration during a directional drilling

Mar 27, 2019

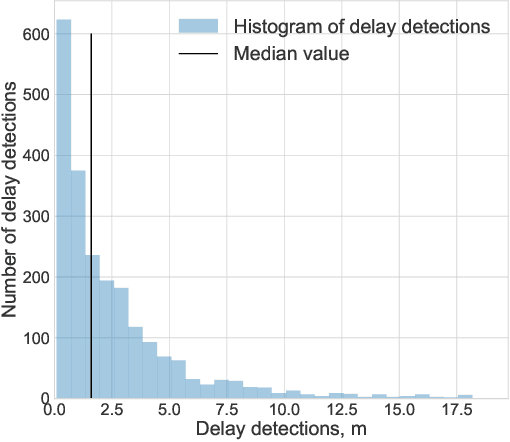

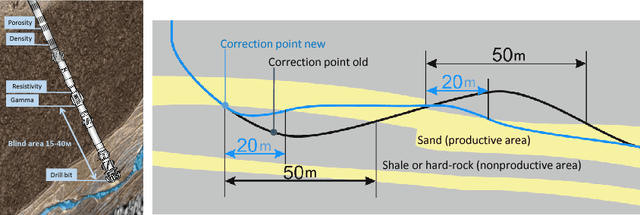

Abstract:During the directional drilling, a bit may sometimes go to a nonproductive rock layer due to the gap about 20 m between the bit and high-fidelity rock type sensors. The only way to detect the lithotype changes in time is the usage of Measurements While Drilling (MWD) data. However, there are no mathematical modeling approaches that reconstruct the rock type based on MWD data with high accuracy. In this article, we present a data-driven procedure that utilizes MWD data for quick detection of changes in rock type. We propose the approach that combines traditional machine learning based on the solution of the rock type classification problem with change detection procedures rarely used before in Oil & Gas industry. The data come from a newly developed oilfield in the North of Western Siberia. The results suggest that we can detect a significant part of changes in rock type reducing the change detection delay from 20 to 2.6 m and the number of false positive alarms from 71 to 7 per well.

Data-driven model for the identification of the rock type at a drilling bit

Sep 13, 2018

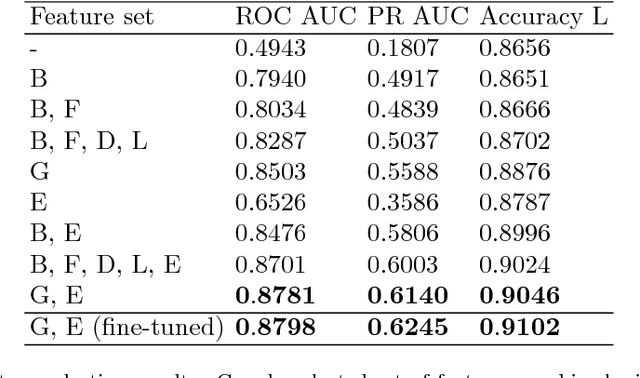

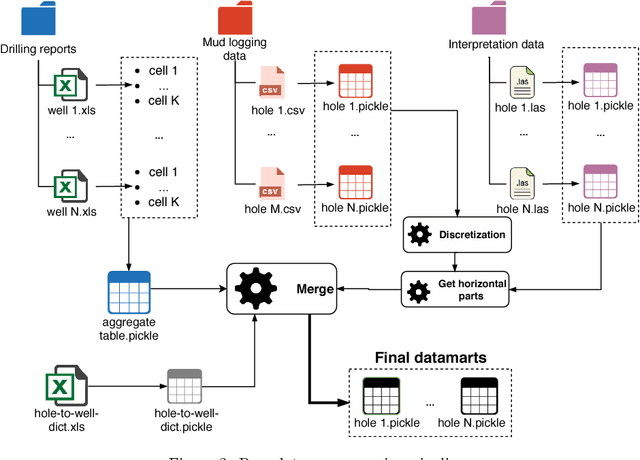

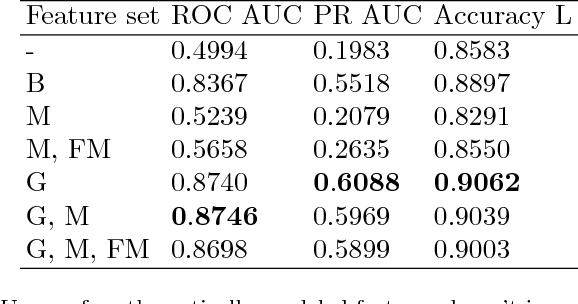

Abstract:In order to bridge the gap of more than 15m between the drilling bit and high-fidelity rock type sensors during the directional drilling, we present a novel approach for identifying rock type at the drilling bit. The approach is based on application of machine learning techniques for Measurements While Drilling (MWD) data. We demonstrate capabilities of the developed approach for distinguishing between the rock types corresponding to (1) a target oil bearing interval of a reservoir and (2) a non-productive shale layer and compare it to more traditional physics-driven approaches. The dataset includes MWD data and lithology mapping along multiple wellbores obtained by processing of Logging While Drilling (LWD) measurements from a massive drilling effort on one of the major newly developed oilfield in the North of Western Siberia. We compare various machine-learning algorithms, examine extra features coming from physical modeling of drilling mechanics, and show that the classification error can be reduced from 13.5% to 9%.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge