Joseph Zhang

Improving SSVEP BCI Spellers With Data Augmentation and Language Models

Dec 28, 2024

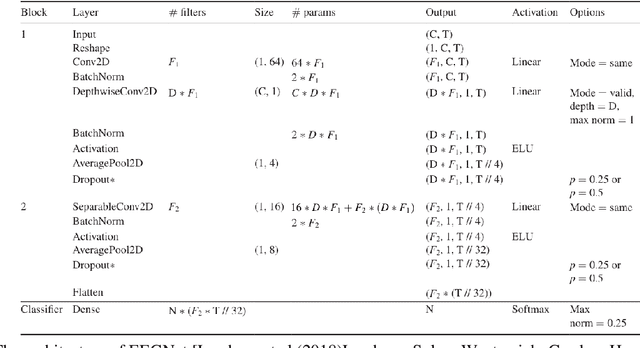

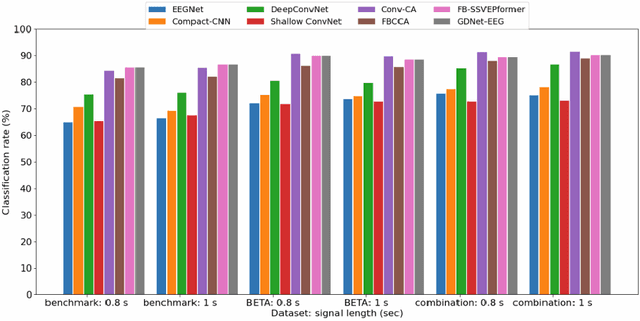

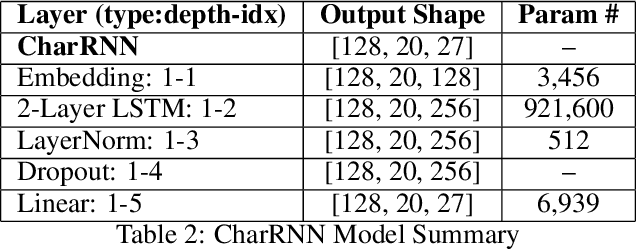

Abstract:Steady-State Visual Evoked Potential (SSVEP) spellers are a promising communication tool for individuals with disabilities. This Brain-Computer Interface utilizes scalp potential data from (electroencephalography) EEG electrodes on a subject's head to decode specific letters or arbitrary targets the subject is looking at on a screen. However, deep neural networks for SSVEP spellers often suffer from low accuracy and poor generalizability to unseen subjects, largely due to the high variability in EEG data. In this study, we propose a hybrid approach combining data augmentation and language modeling to enhance the performance of SSVEP spellers. Using the Benchmark dataset from Tsinghua University, we explore various data augmentation techniques, including frequency masking, time masking, and noise injection, to improve the robustness of deep learning models. Additionally, we integrate a language model (CharRNN) with EEGNet to incorporate linguistic context, significantly enhancing word-level decoding accuracy. Our results demonstrate accuracy improvements of up to 2.9 percent over the baseline, with time masking and language modeling showing the most promise. This work paves the way for more accurate and generalizable SSVEP speller systems, offering improved communication solutions for individuals with disabilities.

Failure Prediction from Limited Hardware Demonstrations

Oct 11, 2024

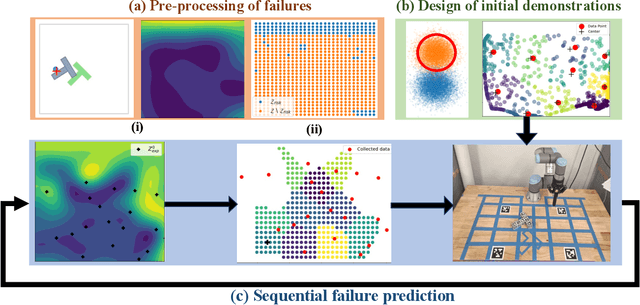

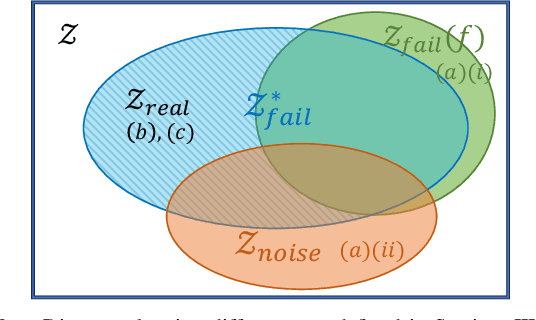

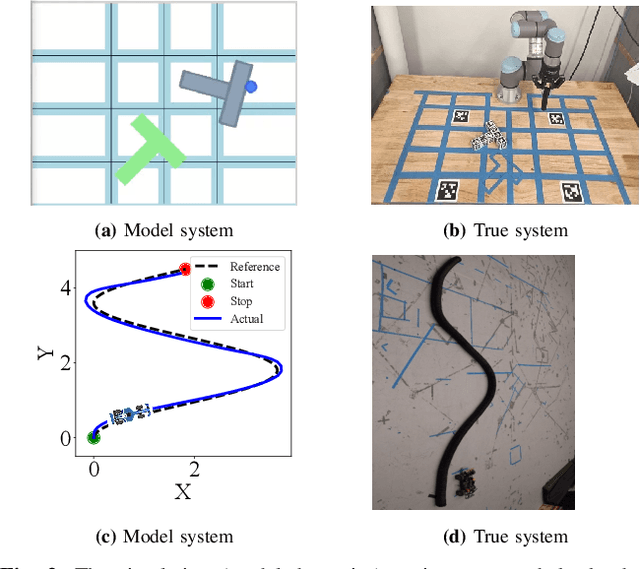

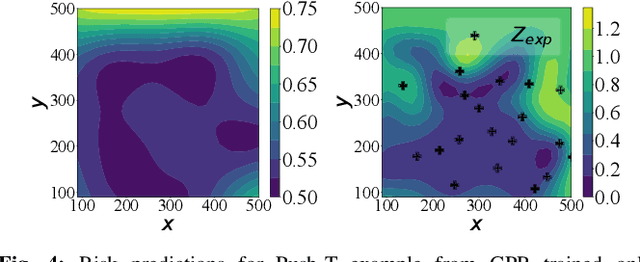

Abstract:Prediction of failures in real-world robotic systems either requires accurate model information or extensive testing. Partial knowledge of the system model makes simulation-based failure prediction unreliable. Moreover, obtaining such demonstrations is expensive, and could potentially be risky for the robotic system to repeatedly fail during data collection. This work presents a novel three-step methodology for discovering failures that occur in the true system by using a combination of a limited number of demonstrations from the true system and the failure information processed through sampling-based testing of a model dynamical system. Given a limited budget $N$ of demonstrations from true system and a model dynamics (with potentially large modeling errors), the proposed methodology comprises of a) exhaustive simulations for discovering algorithmic failures using the model dynamics; b) design of initial $N_1$ demonstrations of the true system using Bayesian inference to learn a Gaussian process regression (GPR)-based failure predictor; and c) iterative $N - N_1$ demonstrations of the true system for updating the failure predictor. To illustrate the efficacy of the proposed methodology, we consider: a) the failure discovery for the task of pushing a T block to a fixed target region with UR3E collaborative robot arm using a diffusion policy; and b) the failure discovery for an F1-Tenth racing car tracking a given raceline under an LQR control policy.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge