John W. Sutherland

Generative manufacturing systems using diffusion models and ChatGPT

May 02, 2024

Abstract:In this study, we introduce Generative Manufacturing Systems (GMS) as a novel approach to effectively manage and coordinate autonomous manufacturing assets, thereby enhancing their responsiveness and flexibility to address a wide array of production objectives and human preferences. Deviating from traditional explicit modeling, GMS employs generative AI, including diffusion models and ChatGPT, for implicit learning from envisioned futures, marking a shift from a model-optimum to a training-sampling decision-making. Through the integration of generative AI, GMS enables complex decision-making through interactive dialogue with humans, allowing manufacturing assets to generate multiple high-quality global decisions that can be iteratively refined based on human feedback. Empirical findings showcase GMS's substantial improvement in system resilience and responsiveness to uncertainties, with decision times reduced from seconds to milliseconds. The study underscores the inherent creativity and diversity in the generated solutions, facilitating human-centric decision-making through seamless and continuous human-machine interactions.

Anomaly Detection and Inter-Sensor Transfer Learning on Smart Manufacturing Datasets

Jun 13, 2022

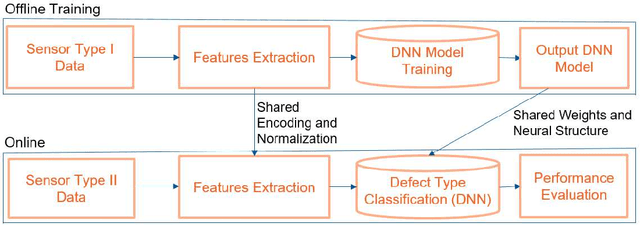

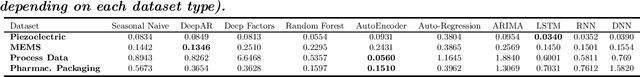

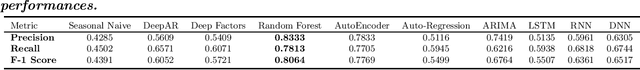

Abstract:Smart manufacturing systems are being deployed at a growing rate because of their ability to interpret a wide variety of sensed information and act on the knowledge gleaned from system observations. In many cases, the principal goal of the smart manufacturing system is to rapidly detect (or anticipate) failures to reduce operational cost and eliminate downtime. This often boils down to detecting anomalies within the sensor date acquired from the system. The smart manufacturing application domain poses certain salient technical challenges. In particular, there are often multiple types of sensors with varying capabilities and costs. The sensor data characteristics change with the operating point of the environment or machines, such as, the RPM of the motor. The anomaly detection process therefore has to be calibrated near an operating point. In this paper, we analyze four datasets from sensors deployed from manufacturing testbeds. We evaluate the performance of several traditional and ML-based forecasting models for predicting the time series of sensor data. Then, considering the sparse data from one kind of sensor, we perform transfer learning from a high data rate sensor to perform defect type classification. Taken together, we show that predictive failure classification can be achieved, thus paving the way for predictive maintenance.

Anomaly Detection through Transfer Learning in Agriculture and Manufacturing IoT Systems

Feb 11, 2021

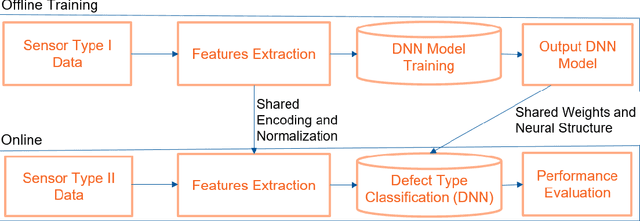

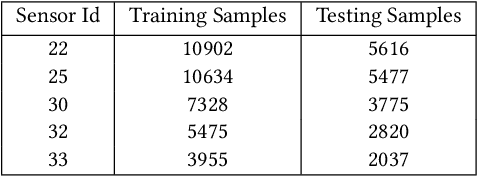

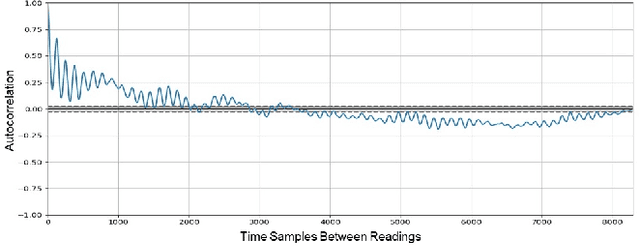

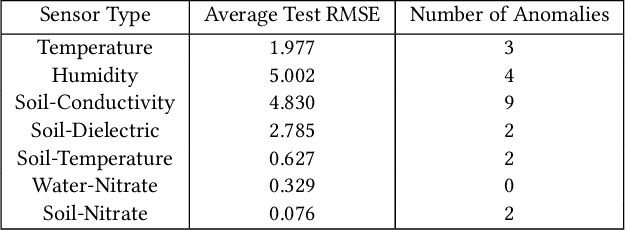

Abstract:IoT systems have been facing increasingly sophisticated technical problems due to the growing complexity of these systems and their fast deployment practices. Consequently, IoT managers have to judiciously detect failures (anomalies) in order to reduce their cyber risk and operational cost. While there is a rich literature on anomaly detection in many IoT-based systems, there is no existing work that documents the use of ML models for anomaly detection in digital agriculture and in smart manufacturing systems. These two application domains pose certain salient technical challenges. In agriculture the data is often sparse, due to the vast areas of farms and the requirement to keep the cost of monitoring low. Second, in both domains, there are multiple types of sensors with varying capabilities and costs. The sensor data characteristics change with the operating point of the environment or machines, such as, the RPM of the motor. The inferencing and the anomaly detection processes therefore have to be calibrated for the operating point. In this paper, we analyze data from sensors deployed in an agricultural farm with data from seven different kinds of sensors, and from an advanced manufacturing testbed with vibration sensors. We evaluate the performance of ARIMA and LSTM models for predicting the time series of sensor data. Then, considering the sparse data from one kind of sensor, we perform transfer learning from a high data rate sensor. We then perform anomaly detection using the predicted sensor data. Taken together, we show how in these two application domains, predictive failure classification can be achieved, thus paving the way for predictive maintenance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge