Jean-Sebastien Plante

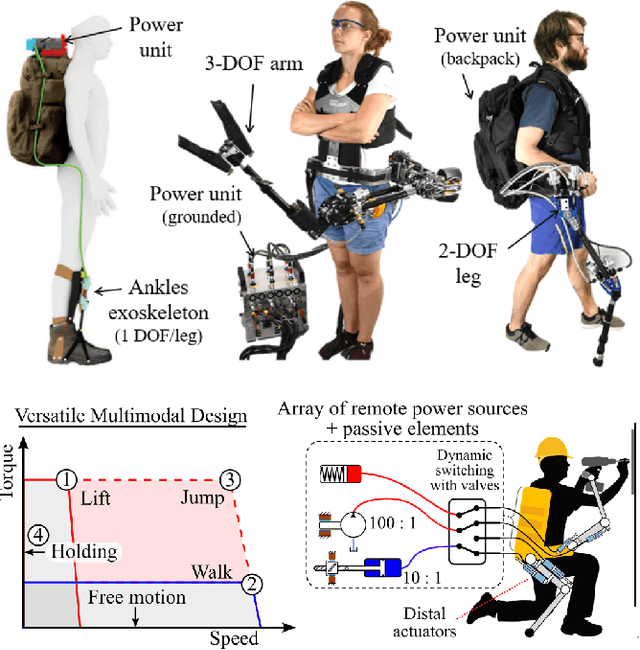

Reconfigurable Hydrostatics: Toward Multifunctional and Powerful Wearable Robotics

Oct 23, 2024Abstract:Wearable and locomotive robot designers face multiple challenges when choosing actuation. Traditional fully actuated designs using electric motors are multifunctional but oversized and inefficient for bearing conservative loads and for being backdrivable. Alternatively, quasi-passive and underactuated designs reduce the size of motorization and energy storage, but are often designed for specific tasks. Designers of versatile and stronger wearable robots will face these challenges unless future actuators become very torque-dense, backdrivable and efficient. This paper explores a design paradigm for addressing this issue: reconfigurable hydrostatics. We show that a hydrostatic actuator can integrate a passive force mechanism and a sharing mechanism in the fluid domain and still be multifunctional. First, an analytical study compares how these two mechanisms can relax the motorization requirements in the context of a load-bearing exoskeleton. Then, the hydrostatic concept integrating these two mechanisms using hydraulic components is presented. A case study analysis shows the mass/efficiency/inertia benefits of the concept over a fully actuated one. Then, the feasibility of the concept is partially validated with a proof-of-concept that actuates the knees of an exoskeleton. The experiments show that it can track the vertical ground reaction force (GRF) profiles of walking, running, squatting, and jumping, and that the energy consumption is 6x lower. The transient force behaviors due to switching from one leg to the other are also analyzed along with some mitigation to improve them.

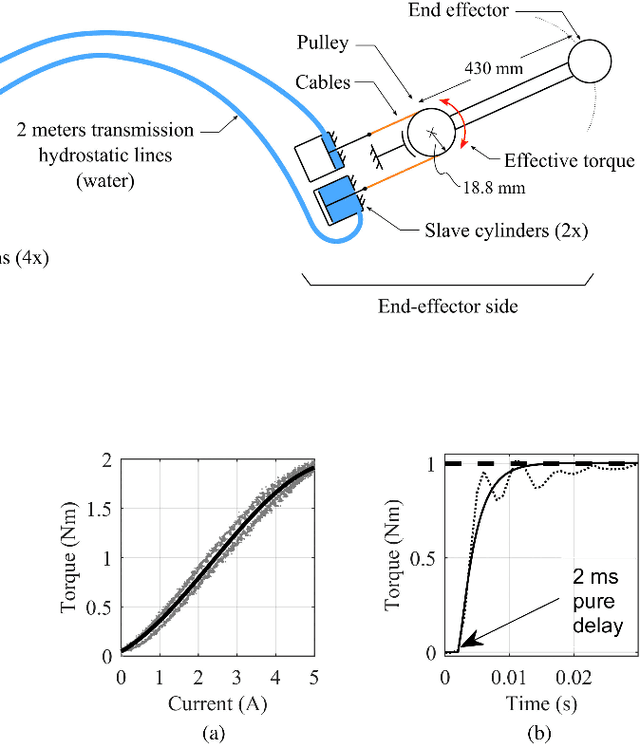

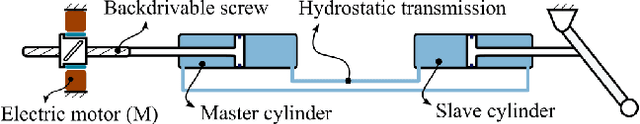

Low-Level Force-Control of MR-Hydrostatic Actuators

Jul 06, 2022

Abstract:Precise and high-fidelity force control is critical for new generations of robots that interact with humans and unknown environments. Mobile robots, such as wearable devices and legged robots, must also be lightweight to accomplish their function. Hydrostatic transmissions have been proposed as a promising strategy for meeting these two challenging requirements. In previous publications, it was shown that using magnetorheological (MR) actuators coupled with hydrostatic transmissions provides high power density and great open-loop human-robot interactions. Still, the open-loop force fidelity at low and high frequencies are decreased by the transmission's dynamics and by nonlinear friction. This letter compares control strategies for MR-hydrostatic actuator systems to increase its torque fidelity, defined as the bandwidth (measured vs desired torque reference) and transparency (minimizing the undesired forces reflected to the end effector when backdriving the robot). Four control approaches are developed and compared experimentally: (1) Open-loop control with friction compensation; (2) non-collocated pressure feedback; (3) collocated pressure feedback; (4) LQGI state feedback. A dither strategy is also implemented to smoothen ball screw friction. Results show that approaches (1), (2) and (3) can increase the performances but are facing compromises, while approach (4) can simultaneously improve all metrics. These results show the potential of using control schemes for improving the force control performance of robots using tethered architectures, addressing issues such as transmission dynamics and friction.

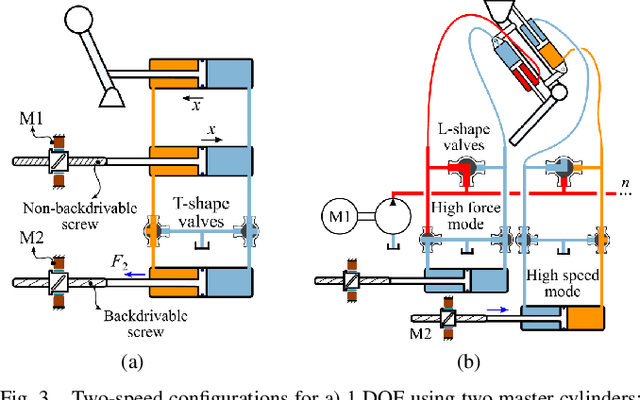

Multimodal Hydrostatic Actuators for Wearable Robots: A Preliminary Assessment of Mass-Saving and Energy-Efficiency Opportunities

Jul 06, 2022

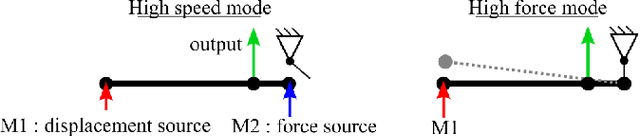

Abstract:Wearable robots are limited by their actuators performances because they must bear the weight of their own power system and energy source. This paper explores the idea of leveraging hybrid modes to meet multiple operating points with a lightweight and efficient system by using hydraulic valves to dynamically reconfigure the connections of a hydrostatic actuator. The analyzed opportunities consist in 1) switching between a highly geared power source or a fast power source, 2) dynamically connecting an energy accumulator and 3) using a locking mechanism for holding. Based on a knee exoskeleton case study analysis, results show that switching between gearing ratio can lead to a lighter and more efficient actuator. Also, results show that using an accumulator to provide a preload continuous force has great mass-saving potential, but does not reduce mass significantly if used as a power booster for short transients. Finally, using a locking valve can slightly reduce battery mass if the work cycle includes frequent stops. The operating principles of the proposed multimodal schemes are demonstrated with a one-DOF prototype.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge