Multimodal Hydrostatic Actuators for Wearable Robots: A Preliminary Assessment of Mass-Saving and Energy-Efficiency Opportunities

Paper and Code

Jul 06, 2022

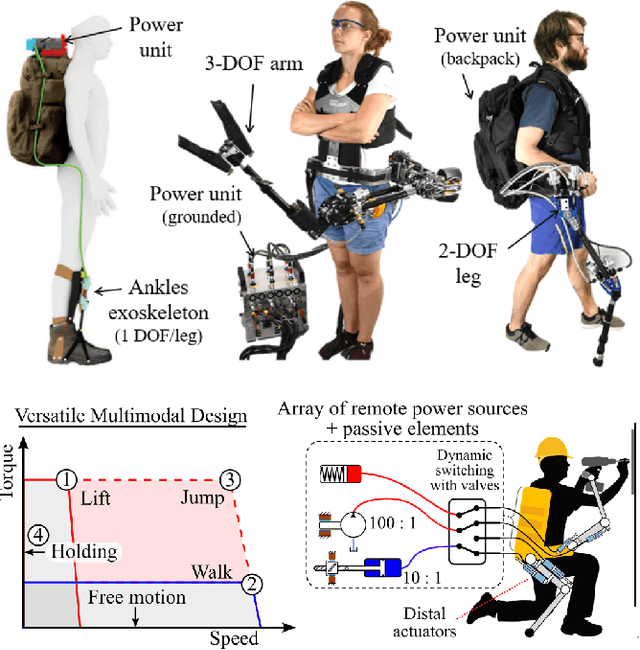

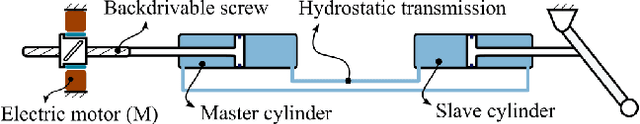

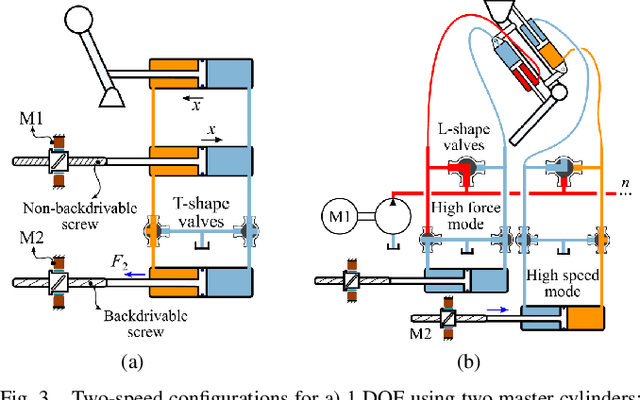

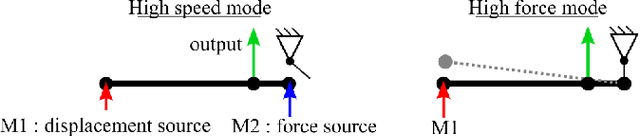

Wearable robots are limited by their actuators performances because they must bear the weight of their own power system and energy source. This paper explores the idea of leveraging hybrid modes to meet multiple operating points with a lightweight and efficient system by using hydraulic valves to dynamically reconfigure the connections of a hydrostatic actuator. The analyzed opportunities consist in 1) switching between a highly geared power source or a fast power source, 2) dynamically connecting an energy accumulator and 3) using a locking mechanism for holding. Based on a knee exoskeleton case study analysis, results show that switching between gearing ratio can lead to a lighter and more efficient actuator. Also, results show that using an accumulator to provide a preload continuous force has great mass-saving potential, but does not reduce mass significantly if used as a power booster for short transients. Finally, using a locking valve can slightly reduce battery mass if the work cycle includes frequent stops. The operating principles of the proposed multimodal schemes are demonstrated with a one-DOF prototype.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge