Hanyi Li

How to Integrate Digital Twin and Virtual Reality in Robotics Systems? Design and Implementation for Providing Robotics Maintenance Services in Data Centers

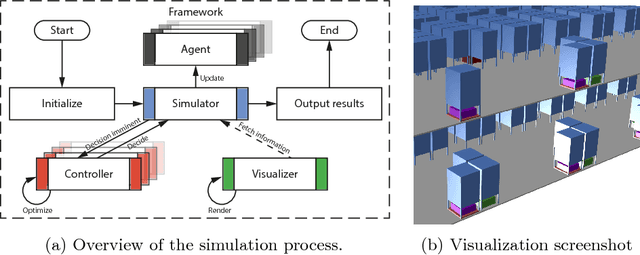

Dec 20, 2023Abstract:In the context of Industry 4.0, the physical and digital worlds are closely connected, and robots are widely used to achieve system automation. Digital twin solutions have contributed significantly to the growth of Industry 4.0. Combining various technologies is a trend that aims to improve system performance. For example, digital twinning can be combined with virtual reality in automated systems. This paper proposes a new concept to articulate this combination, which has mainly been implemented in engineering research projects. However, there are currently no guidelines, plans, or concepts to articulate this combination. The concept will be implemented in data centers, which are crucial for enabling virtual tasks in our daily lives. Due to the COVID-19 pandemic, there has been a surge in demand for services such as e-commerce and videoconferencing. Regular maintenance is necessary to ensure uninterrupted and reliable services. Manual maintenance strategies may not be sufficient to meet the current high demand, and innovative approaches are needed to address the problem. This paper presents a novel approach to data center maintenance: real-time monitoring by an autonomous robot. The robot is integrated with digital twins of assets and a virtual reality interface that allows human personnel to control it and respond to alarms. This methodology enables faster, more cost-effective, and higher quality data center maintenance. It has been validated in a real data centre and can be used for intelligent monitoring and management through joint data sources. The method has potential applications in other automated systems.

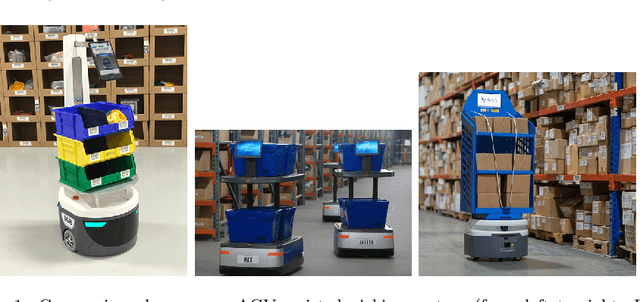

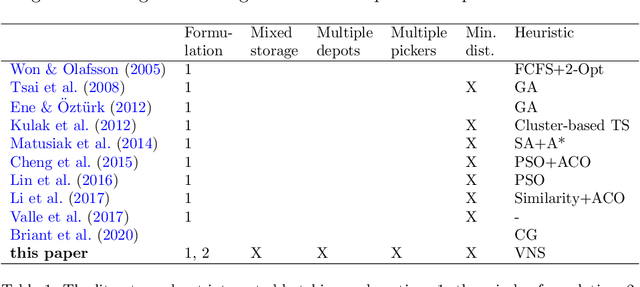

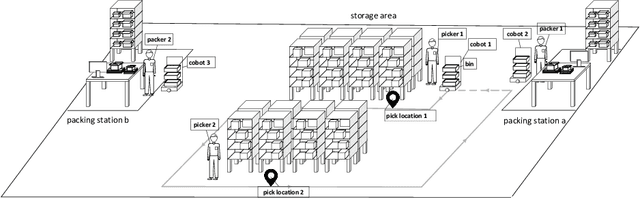

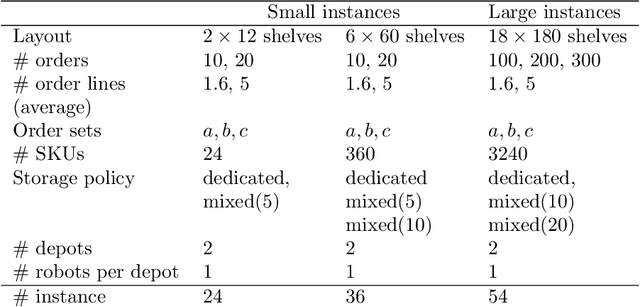

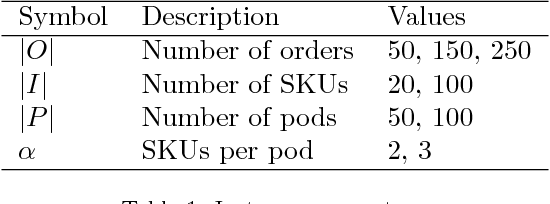

Formulating and solving integrated order batching and routing in multi-depot AGV-assisted mixed-shelves warehouses

Jan 27, 2021

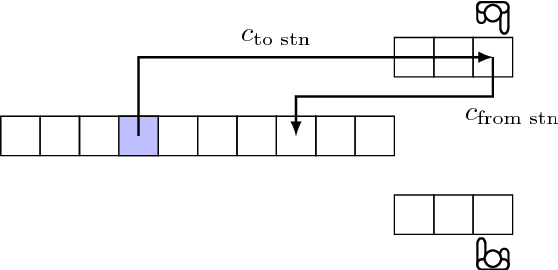

Abstract:Different retail and e-commerce companies are facing the challenge of assembling large numbers of time-critical picking orders that include both single-line and multi-line orders. To reduce unproductive picker working time as in traditional picker-to-parts warehousing systems, different solutions are proposed in the literature and in practice. For example, in a mixed-shelves storage policy, items of the same stock keeping unit are spread over several shelves in a warehouse; or automated guided vehicles (AGVs) are used to transport the picked items from the storage area to packing stations instead of human pickers. This is the first paper to combine both solutions, creating what we call AGV-assisted mixed-shelves picking systems. We model the new integrated order batching and routing problem in such systems as an extended multi-depot vehicle routing problem with both three-index and two-commodity network flow formulations. Due to the complexity of the integrated problem, we develop a novel variable neighborhood search algorithm to solve the integrated problem more efficiently. We test our methods with different sizes of instances, and conclude that the mixed-shelves storage policy is more suitable than the usual storage policy in AGV-assisted mixed-shelves systems for both single-line and multi-line orders (saving up to 67% on driving distances for AGVs). Our variable neighborhood search algorithm provides close-to-optimal solutions within an acceptable computational time.

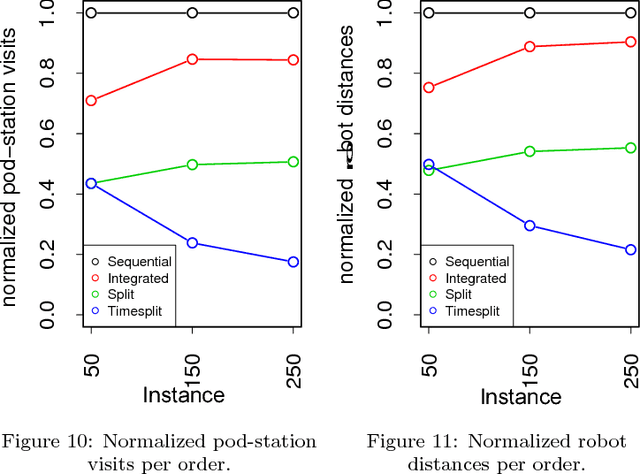

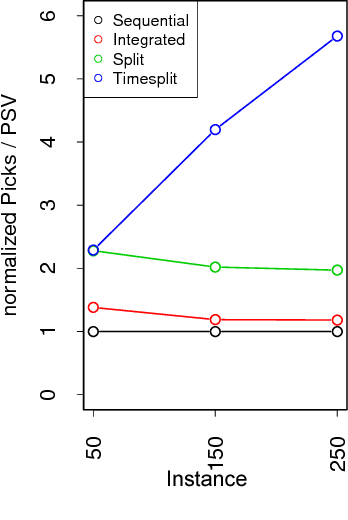

Efficient order picking methods in robotic mobile fulfillment systems

Jan 31, 2019

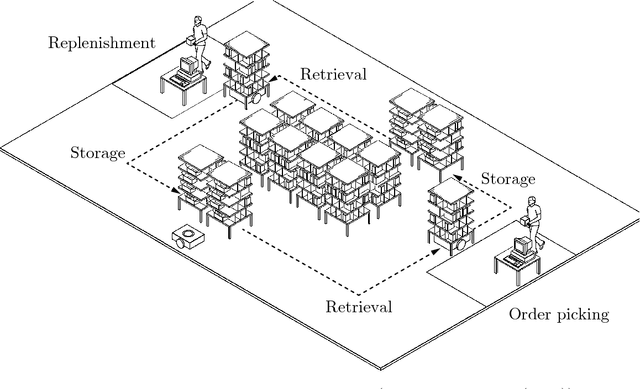

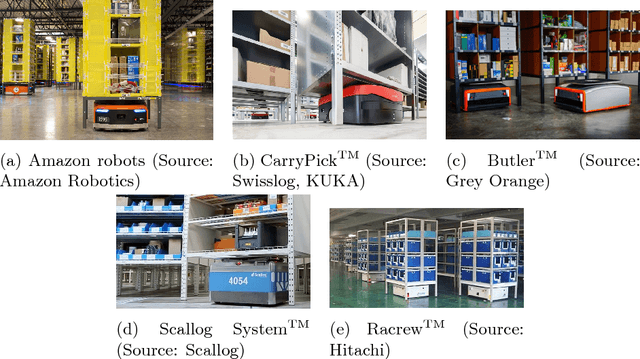

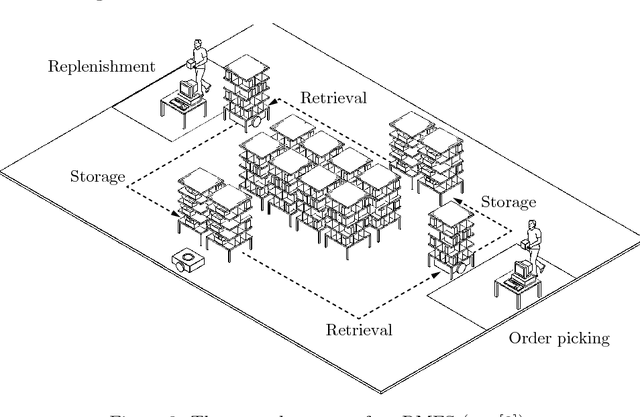

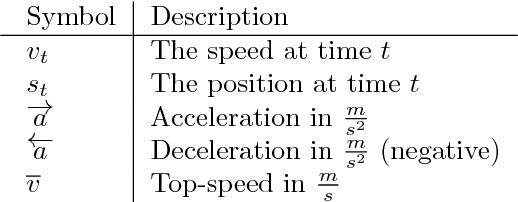

Abstract:Robotic mobile fulfillment systems (RMFSs) are a new type of warehousing system, which has received more attention recently, due to increasing growth in the e-commerce sector. Instead of sending pickers to the inventory area to search for and pick the ordered items, robots carry shelves (called "pods") including ordered items from the inventory area to picking stations. In the picking stations, human pickers put ordered items into totes; then these items are transported by a conveyor to the packing stations. This type of warehousing system relieves the human pickers and improves the picking process. In this paper, we concentrate on decisions about the assignment of pods to stations and orders to stations to fulfill picking for each incoming customer's order. In previous research for an RMFS with multiple picking stations, these decisions are made sequentially. Instead, we present a new integrated model. To improve the system performance even more, we extend our model by splitting orders. This means parts of an order are allowed to be picked at different stations. To the best of the authors' knowledge, this is the first publication on split orders in an RMFS. We analyze different performance metrics, such as pile-on, pod-station visits, robot moving distance and order turn-over time. We compare the results of our models in different instances with the sequential method in our open-source simulation framework RAWSim-O.

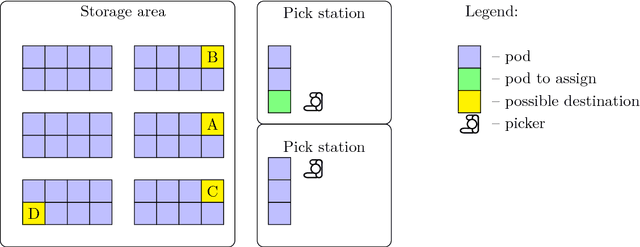

Deterministic Pod Repositioning Problem in Robotic Mobile Fulfillment Systems

Oct 09, 2018

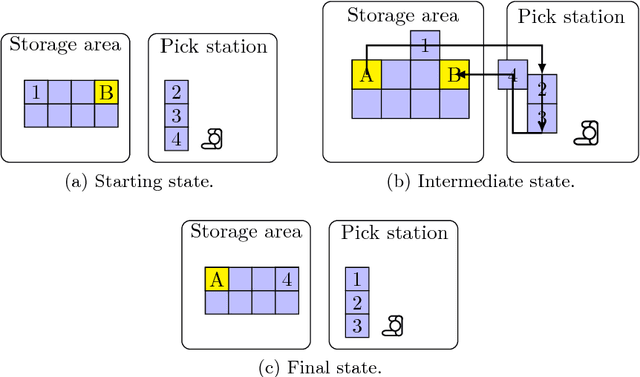

Abstract:In a robotic mobile fulfillment system, robots bring shelves, called pods, with storage items from the storage area to pick stations. At every pick station there is a person -- the picker -- who takes parts from the pod and packs them into boxes according to orders. Usually there are multiple shelves at the pick station. In this case, they build a queue with the picker at its head. When the picker does not need the pod any more, a robot transports the pod back to the storage area. At that time, we need to answer a question: "Where is the optimal place in the inventory to put this pod back?". It is a tough question, because there are many uncertainties to consider before answering it. Moreover, each decision made to answer the question influences the subsequent ones. The goal of this paper is to answer the question properly. We call this problem the Pod Repositioning Problem and formulate a deterministic model. This model is tested with different algorithms, including binary integer programming, cheapest place, fixed place, random place, genetic algorithms, and a novel algorithm called tetris.

From Simulation to Real-World Robotic Mobile Fulfillment Systems

Oct 08, 2018

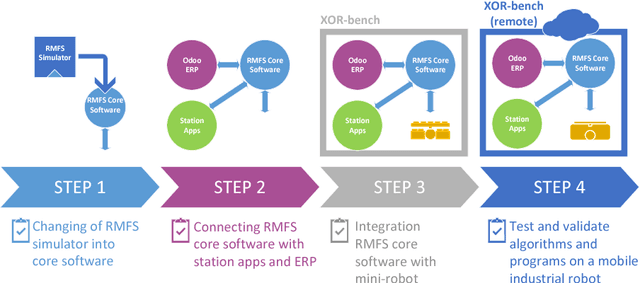

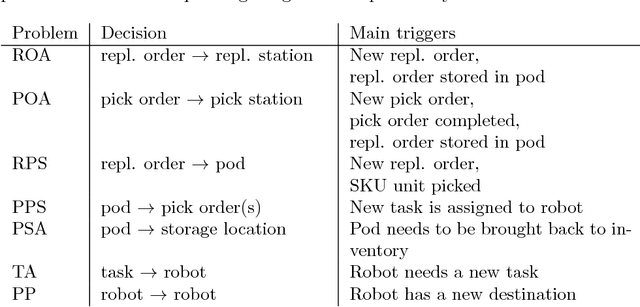

Abstract:In a new type of automated parts-to-picker warehouse system - a Robotic Mobile Fulfillment System (RMFS) - robots are sent to transport pods (movable shelves) to human operators at stations to pick/put items from/to pods. There are many operational decision problems in such a system, and some of them are interdependent and influence each other. In order to analyze the decision problems and the relationships between them, there are two open-source simulation frameworks in the literature, Alphabet Soup and RAWSim-O. However, the steps between simulation and real-world RMFS are not clear in the literature. Therefore, this paper aims to bridge this gap. The simulator is firstly transferred as core software. The core software is connected with an open-source ERP system, called Odoo, while it is also connected with real robots and stations through an XOR-bench. The XOR-bench enables the RMFS to be integrated with several mini-robots and mobile industrial robots in (removed) experiments for the purpose of research and education.

RAWSim-O: A Simulation Framework for Robotic Mobile Fulfillment Systems

Nov 01, 2017

Abstract:This paper deals with a new type of warehousing system, Robotic Mobile Fulfillment Systems (RMFS). In such systems, robots are sent to carry storage units, so-called "pods", from the inventory and bring them to human operators working at stations. At the stations, the items are picked according to customers' orders. There exist new decision problems in such systems, for example, the reallocation of pods after their visits at work stations or the selection of pods to fulfill orders. In order to analyze decision strategies for these decision problems and relations between them, we develop a simulation framework called "RAWSim-O" in this paper. Moreover, we show a real-world application of our simulation framework by integrating simple robot prototypes based on vacuum cleaning robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge