Nils Thieme

Efficient order picking methods in robotic mobile fulfillment systems

Jan 31, 2019

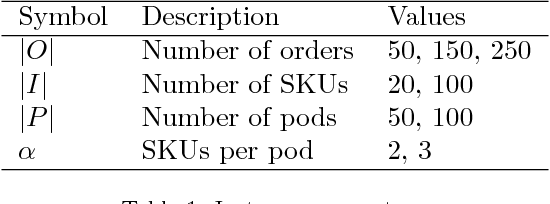

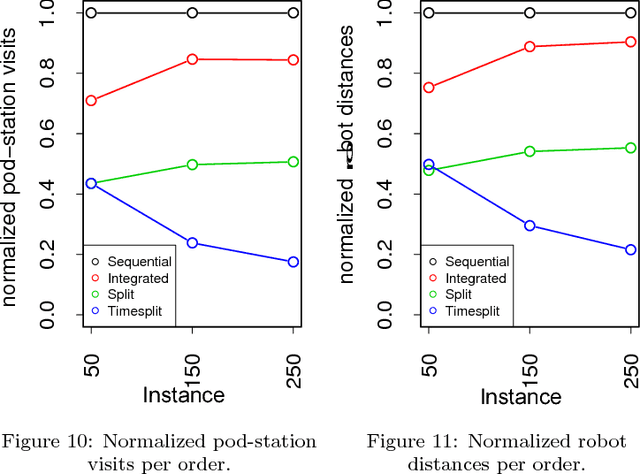

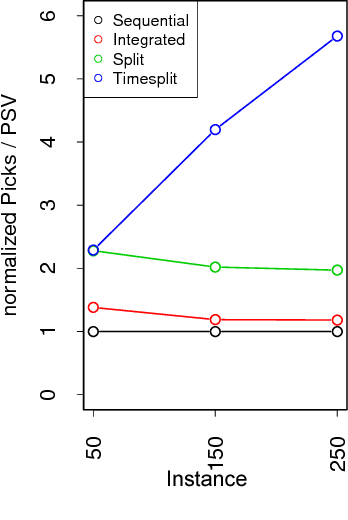

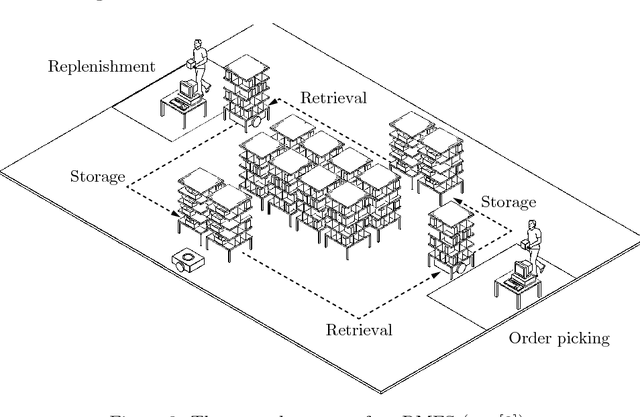

Abstract:Robotic mobile fulfillment systems (RMFSs) are a new type of warehousing system, which has received more attention recently, due to increasing growth in the e-commerce sector. Instead of sending pickers to the inventory area to search for and pick the ordered items, robots carry shelves (called "pods") including ordered items from the inventory area to picking stations. In the picking stations, human pickers put ordered items into totes; then these items are transported by a conveyor to the packing stations. This type of warehousing system relieves the human pickers and improves the picking process. In this paper, we concentrate on decisions about the assignment of pods to stations and orders to stations to fulfill picking for each incoming customer's order. In previous research for an RMFS with multiple picking stations, these decisions are made sequentially. Instead, we present a new integrated model. To improve the system performance even more, we extend our model by splitting orders. This means parts of an order are allowed to be picked at different stations. To the best of the authors' knowledge, this is the first publication on split orders in an RMFS. We analyze different performance metrics, such as pile-on, pod-station visits, robot moving distance and order turn-over time. We compare the results of our models in different instances with the sequential method in our open-source simulation framework RAWSim-O.

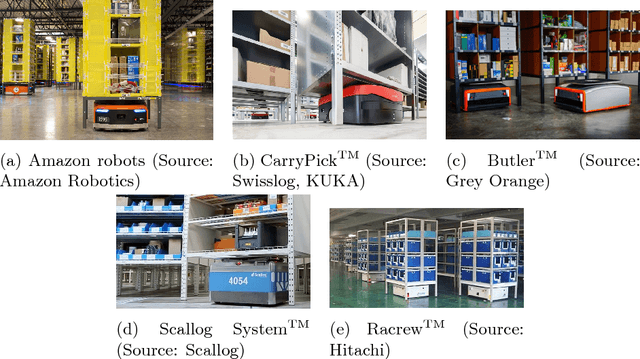

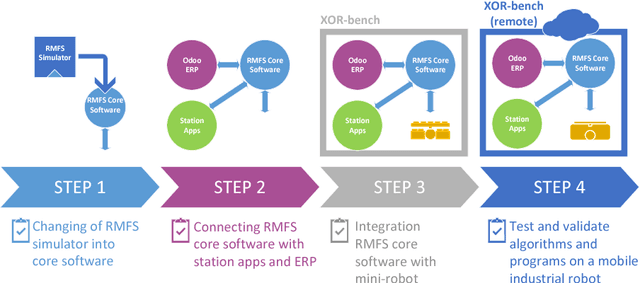

From Simulation to Real-World Robotic Mobile Fulfillment Systems

Oct 08, 2018

Abstract:In a new type of automated parts-to-picker warehouse system - a Robotic Mobile Fulfillment System (RMFS) - robots are sent to transport pods (movable shelves) to human operators at stations to pick/put items from/to pods. There are many operational decision problems in such a system, and some of them are interdependent and influence each other. In order to analyze the decision problems and the relationships between them, there are two open-source simulation frameworks in the literature, Alphabet Soup and RAWSim-O. However, the steps between simulation and real-world RMFS are not clear in the literature. Therefore, this paper aims to bridge this gap. The simulator is firstly transferred as core software. The core software is connected with an open-source ERP system, called Odoo, while it is also connected with real robots and stations through an XOR-bench. The XOR-bench enables the RMFS to be integrated with several mini-robots and mobile industrial robots in (removed) experiments for the purpose of research and education.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge