Giacomo Veneri

Controllable Image Synthesis of Industrial Data Using Stable Diffusion

Jan 06, 2024

Abstract:Training supervised deep neural networks that perform defect detection and segmentation requires large-scale fully-annotated datasets, which can be hard or even impossible to obtain in industrial environments. Generative AI offers opportunities to enlarge small industrial datasets artificially, thus enabling the usage of state-of-the-art supervised approaches in the industry. Unfortunately, also good generative models need a lot of data to train, while industrial datasets are often tiny. Here, we propose a new approach for reusing general-purpose pre-trained generative models on industrial data, ultimately allowing the generation of self-labelled defective images. First, we let the model learn the new concept, entailing the novel data distribution. Then, we force it to learn to condition the generative process, producing industrial images that satisfy well-defined topological characteristics and show defects with a given geometry and location. To highlight the advantage of our approach, we use the synthetic dataset to optimise a crack segmentor for a real industrial use case. When the available data is small, we observe considerable performance increase under several metrics, showing the method's potential in production environments.

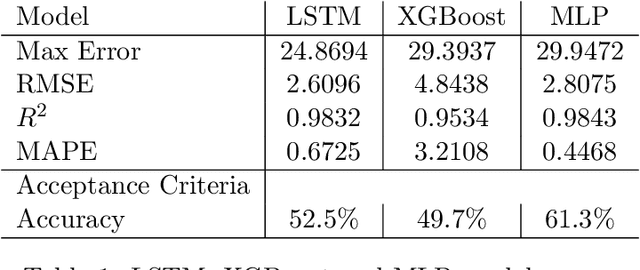

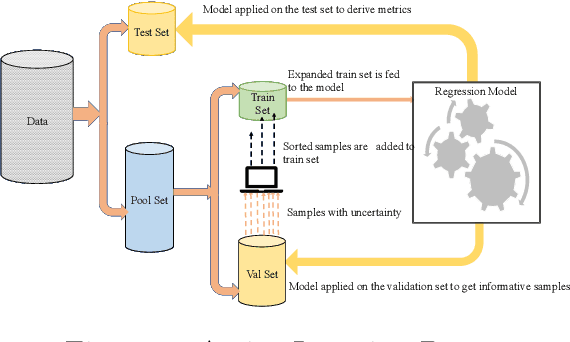

Combining Thermodynamics-based Model of the Centrifugal Compressors and Active Machine Learning for Enhanced Industrial Design Optimization

Sep 06, 2023Abstract:The design process of centrifugal compressors requires applying an optimization process which is computationally expensive due to complex analytical equations underlying the compressor's dynamical equations. Although the regression surrogate models could drastically reduce the computational cost of such a process, the major challenge is the scarcity of data for training the surrogate model. Aiming to strategically exploit the labeled samples, we propose the Active-CompDesign framework in which we combine a thermodynamics-based compressor model (i.e., our internal software for compressor design) and Gaussian Process-based surrogate model within a deployable Active Learning (AL) setting. We first conduct experiments in an offline setting and further, extend it to an online AL framework where a real-time interaction with the thermodynamics-based compressor's model allows the deployment in production. ActiveCompDesign shows a significant performance improvement in surrogate modeling by leveraging on uncertainty-based query function of samples within the AL framework with respect to the random selection of data points. Moreover, our framework in production has reduced the total computational time of compressor's design optimization to around 46% faster than relying on the internal thermodynamics-based simulator, achieving the same performance.

Learning to Identify Drilling Defects in Turbine Blades with Single Stage Detectors

Aug 08, 2022

Abstract:Nondestructive testing (NDT) is widely applied to defect identification of turbine components during manufacturing and operation. Operational efficiency is key for gas turbine OEM (Original Equipment Manufacturers). Automating the inspection process as much as possible, while minimizing the uncertainties involved, is thus crucial. We propose a model based on RetinaNet to identify drilling defects in X-ray images of turbine blades. The application is challenging due to the large image resolutions in which defects are very small and hardly captured by the commonly used anchor sizes, and also due to the small size of the available dataset. As a matter of fact, all these issues are pretty common in the application of Deep Learning-based object detection models to industrial defect data. We overcome such issues using open source models, splitting the input images into tiles and scaling them up, applying heavy data augmentation, and optimizing the anchor size and aspect ratios with a differential evolution solver. We validate the model with $3$-fold cross-validation, showing a very high accuracy in identifying images with defects. We also define a set of best practices which can help other practitioners overcome similar challenges.

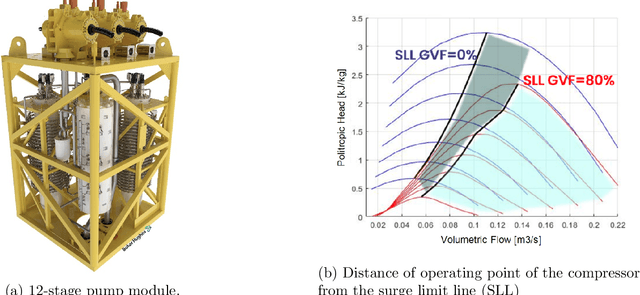

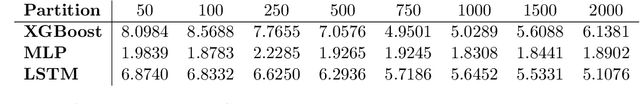

Deep Surrogate of Modular Multi Pump using Active Learning

Aug 04, 2022

Abstract:Due to the high cost and reliability of sensors, the designers of a pump reduce the needed number of sensors for the estimation of the feasible operating point as much as possible. The major challenge to obtain a good estimation is the low amount of data available. Using this amount of data, the performance of the estimation method is not enough to satisfy the client requests. To solve this problem of scarcity of data, getting high quality data is important to obtain a good estimation. Based on these considerations, we develop an active learning framework for estimating the operating point of a Modular Multi Pump used in energy field. In particular we focus on the estimation of the surge distance. We apply Active learning to estimate the surge distance with minimal dataset. Results report that active learning is a valuable technique also for real application.

DANNTe: a case study of a turbo-machinery sensor virtualization under domain shift

Jan 11, 2022

Abstract:We propose an adversarial learning method to tackle a Domain Adaptation (DA) time series regression task (DANNTe). The regression aims at building a virtual copy of a sensor installed on a gas turbine, to be used in place of the physical sensor which can be missing in certain situations. Our DA approach is to search for a domain-invariant representation of the features. The learner has access to both a labelled source dataset and an unlabeled target dataset (unsupervised DA) and is trained on both, exploiting the minmax game between a task regressor and a domain classifier Neural Networks. Both models share the same feature representation, learnt by a feature extractor. This work is based on the results published by Ganin et al. arXiv:1505.07818; indeed, we present an extension suitable to time series applications. We report a significant improvement in regression performance, compared to the baseline model trained on the source domain only.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge