Genevieve Palardy

Next-generation perception system for automated defects detection in composite laminates via polarized computational imaging

Aug 24, 2021

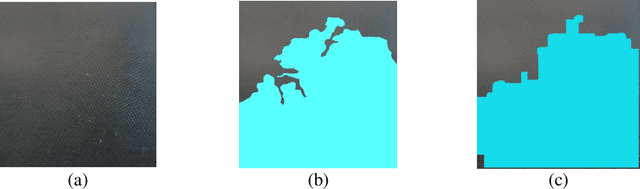

Abstract:Finishing operations on large-scale composite components like wind turbine blades, including trimming and sanding, often require multiple workers and part repositioning. In the composites manufacturing industry, automation of such processes is challenging, as manufactured part geometry may be inconsistent and task completion is based on human judgment and experience. Implementing a mobile, collaborative robotic system capable of performing finishing tasks in dynamic and uncertain environments would improve quality and lower manufacturing costs. To complete the given tasks, the collaborative robotic team must properly understand the environment and detect irregularities in the manufactured parts. In this paper, we describe the initial implementation and demonstration of a polarized computational imaging system to identify defects in composite laminates. As the polarimetric images are highly relevant to the surface micro-geometry, they can be used to detect surface defects that are not visible in conventional color images. The proposed vision system successfully identifies defect types and surface characteristics (e.g., pinholes, voids, scratches, resin flash) for different glass fiber and carbon fiber laminates.

Design and integration of end-effector for 3D printing of novel UV-curable shape memory polymers with a collaborative robotic system

Aug 24, 2021

Abstract:This paper presents the initial development of a robotic additive manufacturing technology based on ultraviolet (UV)-curable thermoset polymers. This is designed to allow free-standing printing through partial UV curing and fiber reinforcement for structural applications. The proposed system integrates a collaborative robotic manipulator with a custom-built extruder end-effector designed specifically for printing with UV-curable polymers. The system was tested using a variety of resin compositions, some reinforced with milled glass fiber (GF) or fumed silica (FS) and small-scale, 2D and 3D specimens were printed. Dimensional stability was analyzed for all formulations, showing that resin containing up to 50 wt% GF or at least 2.8 wt% FS displayed the most accurate dimensions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge