Ganesh Balasubramanian

Machine learning driven search of hydrogen storage materials

Mar 06, 2025

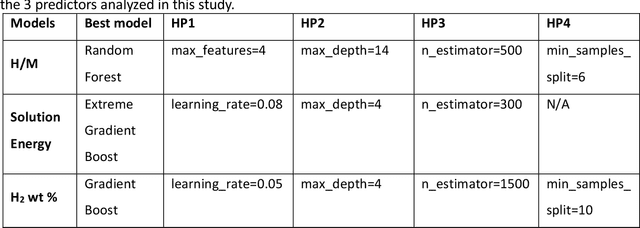

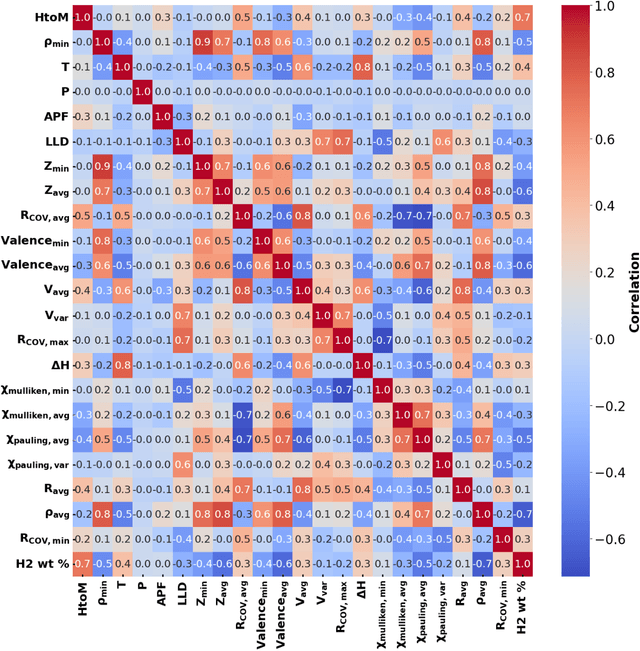

Abstract:The transition to a low-carbon economy demands efficient and sustainable energy-storage solutions, with hydrogen emerging as a promising clean-energy carrier and with metal hydrides recognized for their hydrogen-storage capacity. Here, we leverage machine learning (ML) to predict hydrogen-to-metal (H/M) ratios and solution energy by incorporating thermodynamic parameters and local lattice distortion (LLD) as key features. Our best-performing ML model provides improvements to H/M ratios and solution energies over a broad class of ternary alloys (easily extendable to multi-principal-element alloys), such as Ti-Nb-X (X = Mo, Cr, Hf, Ta, V, Zr) and Co-Ni-X (X = Al, Mg, V). Ti-Nb-Mo alloys reveal compositional effects in H-storage behavior, in particular Ti, Nb, and V enhance H-storage capacity, while Mo reduces H/M and hydrogen weight percent by 40-50%. We attributed to slow hydrogen kinetics in molybdenum rich alloys, which is validated by our pressure-composition isotherm (PCT) experiments on pure Ti and Ti5Mo95 alloys. Density functional theory (DFT) and molecular simulations also confirm that Ti and Nb promote H diffusion, whereas Mo hinders it, highlighting the interplay between electronic structure, lattice distortions, and hydrogen uptake. Notably, our Gradient Boosting Regression model identifies LLD as a critical factor in H/M predictions. To aid material selection, we present two periodic tables illustrating elemental effects on (a) H2 wt% and (b) solution energy, derived from ML, and provide a reference for identifying alloying elements that enhance hydrogen solubility and storage.

3D Deep Learning with voxelized atomic configurations for modeling atomistic potentials in complex solid-solution alloys

Nov 23, 2018

Abstract:The need for advanced materials has led to the development of complex, multi-component alloys or solid-solution alloys. These materials have shown exceptional properties like strength, toughness, ductility, electrical and electronic properties. Current development of such material systems are hindered by expensive experiments and computationally demanding first-principles simulations. Atomistic simulations can provide reasonable insights on properties in such material systems. However, the issue of designing robust potentials still exists. In this paper, we explore a deep convolutional neural-network based approach to develop the atomistic potential for such complex alloys to investigate materials for insights into controlling properties. In the present work, we propose a voxel representation of the atomic configuration of a cell and design a 3D convolutional neural network to learn the interaction of the atoms. Our results highlight the performance of the 3D convolutional neural network and its efficacy in machine-learning the atomistic potential. We also explore the role of voxel resolution and provide insights into the two bounding box methodologies implemented for voxelization.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge