Felix Nilsson

Synthetic Data for Object Classification in Industrial Applications

Dec 09, 2022

Abstract:One of the biggest challenges in machine learning is data collection. Training data is an important part since it determines how the model will behave. In object classification, capturing a large number of images per object and in different conditions is not always possible and can be very time-consuming and tedious. Accordingly, this work explores the creation of artificial images using a game engine to cope with limited data in the training dataset. We combine real and synthetic data to train the object classification engine, a strategy that has shown to be beneficial to increase confidence in the decisions made by the classifier, which is often critical in industrial setups. To combine real and synthetic data, we first train the classifier on a massive amount of synthetic data, and then we fine-tune it on real images. Another important result is that the amount of real images needed for fine-tuning is not very high, reaching top accuracy with just 12 or 24 images per class. This substantially reduces the requirements of capturing a great amount of real data.

Image-Based Fire Detection in Industrial Environments with YOLOv4

Dec 09, 2022Abstract:Fires have destructive power when they break out and affect their surroundings on a devastatingly large scale. The best way to minimize their damage is to detect the fire as quickly as possible before it has a chance to grow. Accordingly, this work looks into the potential of AI to detect and recognize fires and reduce detection time using object detection on an image stream. Object detection has made giant leaps in speed and accuracy over the last six years, making real-time detection feasible. To our end, we collected and labeled appropriate data from several public sources, which have been used to train and evaluate several models based on the popular YOLOv4 object detector. Our focus, driven by a collaborating industrial partner, is to implement our system in an industrial warehouse setting, which is characterized by high ceilings. A drawback of traditional smoke detectors in this setup is that the smoke has to rise to a sufficient height. The AI models brought forward in this research managed to outperform these detectors by a significant amount of time, providing precious anticipation that could help to minimize the effects of fires further.

Visual Detection of Personal Protective Equipment and Safety Gear on Industry Workers

Dec 09, 2022

Abstract:Workplace injuries are common in today's society due to a lack of adequately worn safety equipment. A system that only admits appropriately equipped personnel can be created to improve working conditions. The goal is thus to develop a system that will improve workers' safety using a camera that will detect the usage of Personal Protective Equipment (PPE). To this end, we collected and labeled appropriate data from several public sources, which have been used to train and evaluate several models based on the popular YOLOv4 object detector. Our focus, driven by a collaborating industrial partner, is to implement our system into an entry control point where workers must present themselves to obtain access to a restricted area. Combined with facial identity recognition, the system would ensure that only authorized people wearing appropriate equipment are granted access. A novelty of this work is that we increase the number of classes to five objects (hardhat, safety vest, safety gloves, safety glasses, and hearing protection), whereas most existing works only focus on one or two classes, usually hardhats or vests. The AI model developed provides good detection accuracy at a distance of 3 and 5 meters in the collaborative environment where we aim at operating (mAP of 99/89%, respectively). The small size of some objects or the potential occlusion by body parts have been identified as potential factors that are detrimental to accuracy, which we have counteracted via data augmentation and cropping of the body before applying PPE detection.

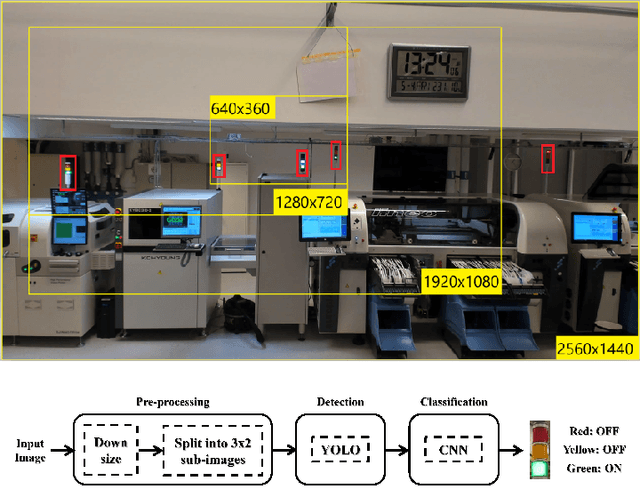

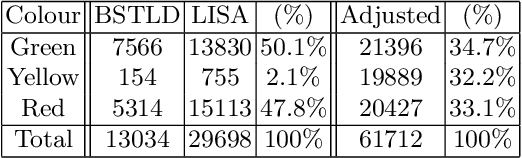

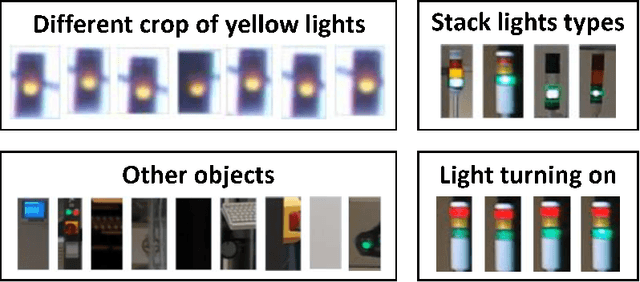

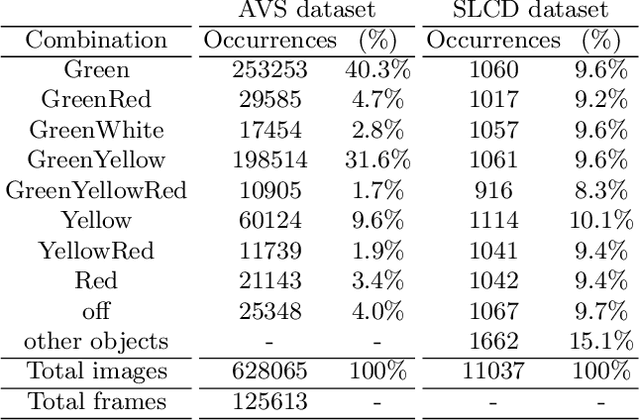

Detection and Classification of Industrial Signal Lights for Factory Floors

May 28, 2020

Abstract:Industrial manufacturing has developed during the last decades from a labor-intensive manual control of machines to a fully-connected automated process. The next big leap is known as industry 4.0, or smart manufacturing. With industry 4.0 comes increased integration between IT systems and the factory floor from the customer order system to final delivery of the product. One benefit of this integration is mass production of individually customized products. However, this has proven challenging to implement into existing factories, considering that their lifetime can be up to 30 years. The single most important parameter to measure in a factory is the operating hours of each machine. Operating hours can be affected by machine maintenance as well as re-configuration for different products. For older machines without connectivity, the operating state is typically indicated by signal lights of green, yellow and red colours. Accordingly, the goal is to develop a solution which can measure the operational state using the input from a video camera capturing a factory floor. Using methods commonly employed for traffic light recognition in autonomous cars, a system with an accuracy of over 99% in the specified conditions is presented. It is believed that if more diverse video data becomes available, a system with high reliability that generalizes well could be developed using a similar methodology.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge