Detection and Classification of Industrial Signal Lights for Factory Floors

Paper and Code

May 28, 2020

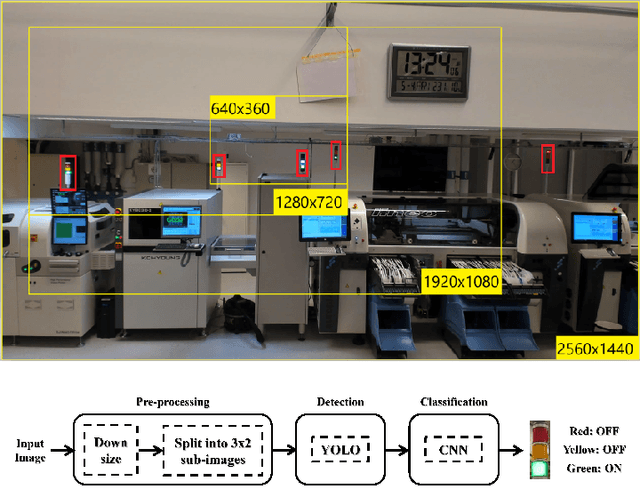

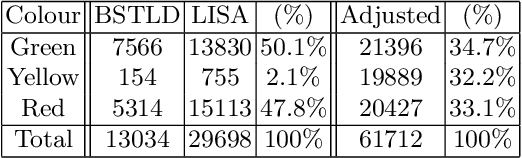

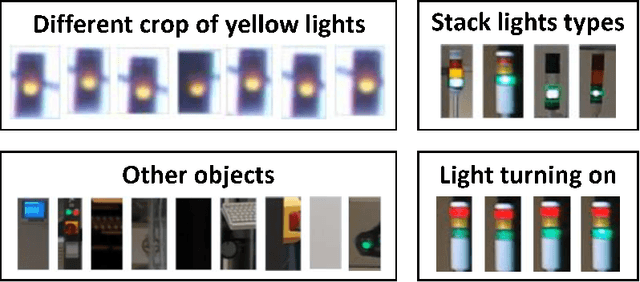

Industrial manufacturing has developed during the last decades from a labor-intensive manual control of machines to a fully-connected automated process. The next big leap is known as industry 4.0, or smart manufacturing. With industry 4.0 comes increased integration between IT systems and the factory floor from the customer order system to final delivery of the product. One benefit of this integration is mass production of individually customized products. However, this has proven challenging to implement into existing factories, considering that their lifetime can be up to 30 years. The single most important parameter to measure in a factory is the operating hours of each machine. Operating hours can be affected by machine maintenance as well as re-configuration for different products. For older machines without connectivity, the operating state is typically indicated by signal lights of green, yellow and red colours. Accordingly, the goal is to develop a solution which can measure the operational state using the input from a video camera capturing a factory floor. Using methods commonly employed for traffic light recognition in autonomous cars, a system with an accuracy of over 99% in the specified conditions is presented. It is believed that if more diverse video data becomes available, a system with high reliability that generalizes well could be developed using a similar methodology.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge