Erik Stöhr

General Hand Guidance Framework using Microsoft HoloLens

Aug 13, 2019

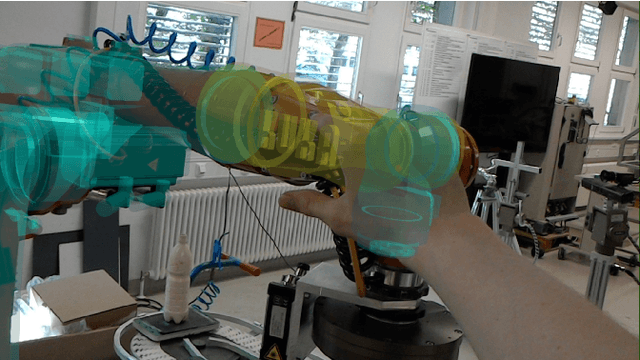

Abstract:Hand guidance emerged from the safety requirements for collaborative robots, namely possessing joint-torque sensors. Since then it has proven to be a powerful tool for easy trajectory programming, allowing lay-users to reprogram robots intuitively. Going beyond, a robot can learn tasks by user demonstrations through kinesthetic teaching, enabling robots to generalise tasks and further reducing the need for reprogramming. However, hand guidance is still mostly relegated to collaborative robots. Here we propose a method that doesn't require any sensors on the robot or in the robot cell, by using a Microsoft HoloLens augmented reality head mounted display. We reference the robot using a registration algorithm to match the robot model to the spatial mesh. The in-built hand tracking and localisation capabilities are then used to calculate the position of the hands relative to the robot. By decomposing the hand movements into orthogonal rotations and propagating it down through the kinematic chain, we achieve a generalised hand guidance without the need to build a dynamic model of the robot itself. We tested our approach on a commonly used industrial manipulator, the KUKA KR-5.

Sensorless Hand Guidance using Microsoft Hololens

Jan 15, 2019

Abstract:Hand guidance of robots has proven to be a useful tool both for programming trajectories and in kinesthetic teaching. However hand guidance is usually relegated to robots possessing joint-torque sensors (JTS). Here we propose to extend hand guidance to robots lacking those sensors through the use of an Augmented Reality (AR) device, namely Microsoft's Hololens. Augmented reality devices have been envisioned as a helpful addition to ease both robot programming and increase situational awareness of humans working in close proximity to robots. We reference the robot by using a registration algorithm to match a robot model to the spatial mesh. The in-built hand tracking capabilities are then used to calculate the position of the hands relative to the robot. By decomposing the hand movements into orthogonal rotations we achieve a completely sensorless hand guidance without any need to build a dynamic model of the robot itself. We did the first tests our approach on a commonly used industrial manipulator, the KUKA KR-5.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge