Emre Cemal Gonen

Multi-segmented Adaptive Feet for Versatile Legged Locomotion in Natural Terrain

Sep 18, 2022

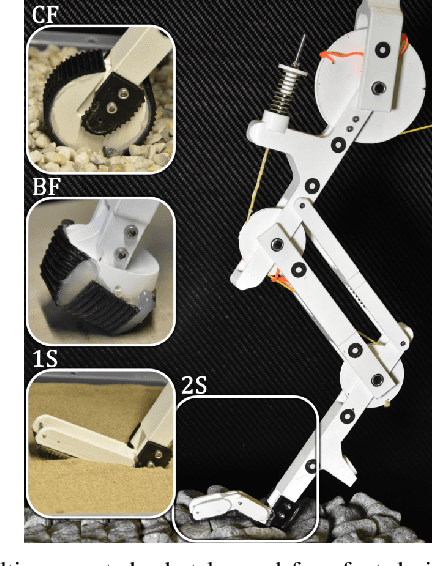

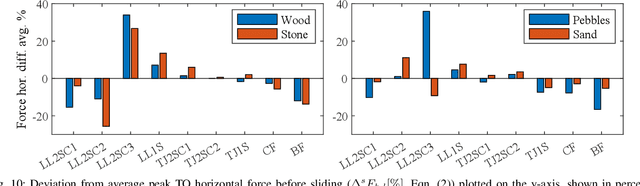

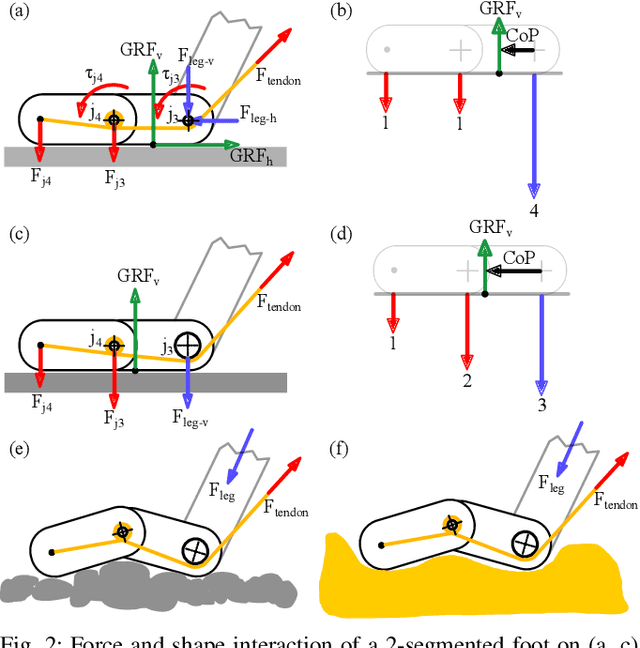

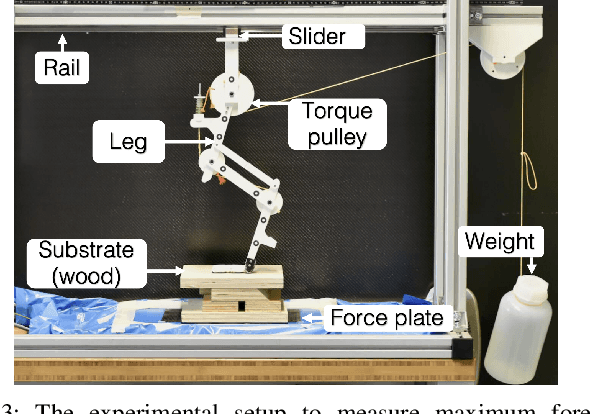

Abstract:Most legged robots are built with leg structures from serially mounted links and actuators and are controlled through complex controllers and sensor feedback. In comparison, animals developed multi-segment legs, mechanical coupling between joints, and multi-segmented feet. They run agile over all terrains, arguably with simpler locomotion control. Here we focus on developing foot mechanisms that resist slipping and sinking also in natural terrain. We present first results of multi-segment feet mounted to a bird-inspired robot leg with multi-joint mechanical tendon coupling. Our one- and two-segment, mechanically adaptive feet show increased viable horizontal forces on multiple soft and hard substrates before starting to slip. We also observe that segmented feet reduce sinking on soft substrates compared to ball-feet and cylinder-feet. We report how multi-segmented feet provide a large range of viable centre of pressure points well suited for bipedal robots, but also for quadruped robots on slopes and natural terrain. Our results also offer a functional understanding of segmented feet in animals like ratite birds.

Investigation on a bipedal robot: Why do humans need both Soleus andGastrocnemius muscles for ankle push-off during walking?

Mar 03, 2022

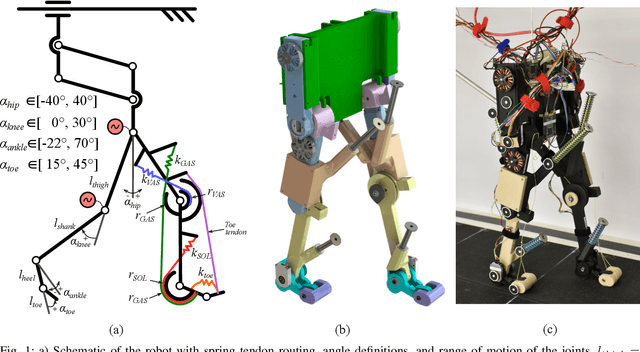

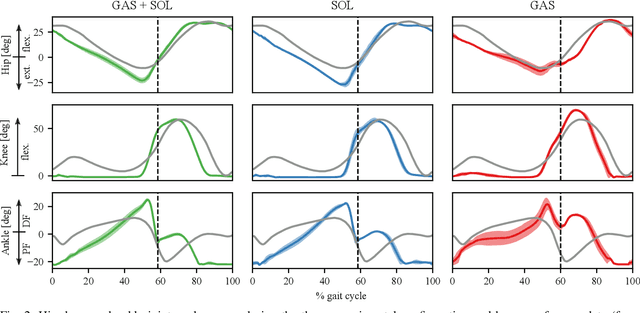

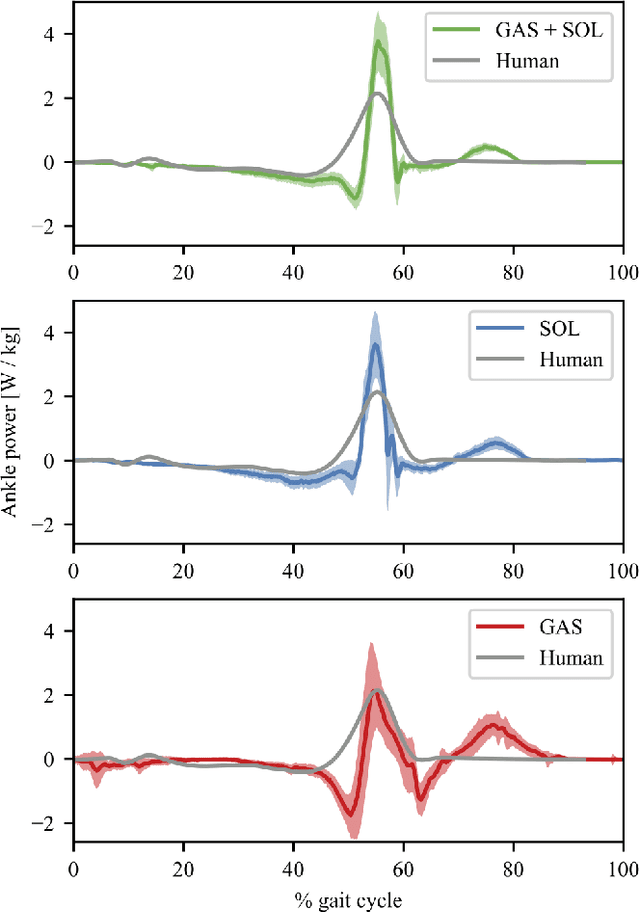

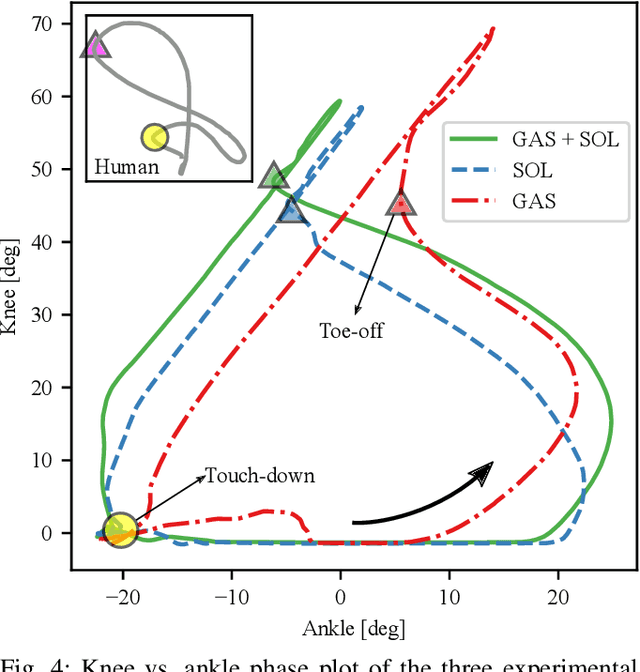

Abstract:Legged locomotion in humans is influenced by mechanics and neural control. One mechanism assumed to contribute to the high efficiency of human walking is the impulsive ankle push-off, which potentially powers the human swing leg catapult. However, the mechanics of the human's lower leg with its complex muscle-tendon units spanning over single and multiple joints is not yet understood. Legged robots allow testing the interaction between complex leg mechanics, control, and environment in real-world walking gait. We custom developed a small, 2.2 kg human-like bipedal robot with soleus and gastrocnemius muscles represented by linear springs, acting as mono- and biarticular elasticities around the robot's ankle and knee joints. We tested the influence of three soleus and gastrocnemius spring configurations on the ankle power curves, on the synchronization of the ankle and knee joint movements, on the total cost of transport, and on walking speed. We controlled the robot with a feed-forward central pattern generator, leading to walking speeds between 0.35 m/s and 0.57 m/s at 1.0 Hz locomotion frequency, at 0.35 m leg length. We found differences between all three configurations; the soleus spring supports the robot's speed and energy efficiency by ankle power amplification, while the GAS spring facilitates the synchronization between knee and ankle joints during push-off.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge