Ellen Otte

Uncertainty Quantification Using Ensemble Learning and Monte Carlo Sampling for Performance Prediction and Monitoring in Cell Culture Processes

Sep 03, 2024

Abstract:Biopharmaceutical products, particularly monoclonal antibodies (mAbs), have gained prominence in the pharmaceutical market due to their high specificity and efficacy. As these products are projected to constitute a substantial portion of global pharmaceutical sales, the application of machine learning models in mAb development and manufacturing is gaining momentum. This paper addresses the critical need for uncertainty quantification in machine learning predictions, particularly in scenarios with limited training data. Leveraging ensemble learning and Monte Carlo simulations, our proposed method generates additional input samples to enhance the robustness of the model in small training datasets. We evaluate the efficacy of our approach through two case studies: predicting antibody concentrations in advance and real-time monitoring of glucose concentrations during bioreactor runs using Raman spectra data. Our findings demonstrate the effectiveness of the proposed method in estimating the uncertainty levels associated with process performance predictions and facilitating real-time decision-making in biopharmaceutical manufacturing. This contribution not only introduces a novel approach for uncertainty quantification but also provides insights into overcoming challenges posed by small training datasets in bioprocess development. The evaluation demonstrates the effectiveness of our method in addressing key challenges related to uncertainty estimation within upstream cell cultivation, illustrating its potential impact on enhancing process control and product quality in the dynamic field of biopharmaceuticals.

Applications of Machine Learning in Biopharmaceutical Process Development and Manufacturing: Current Trends, Challenges, and Opportunities

Oct 16, 2023

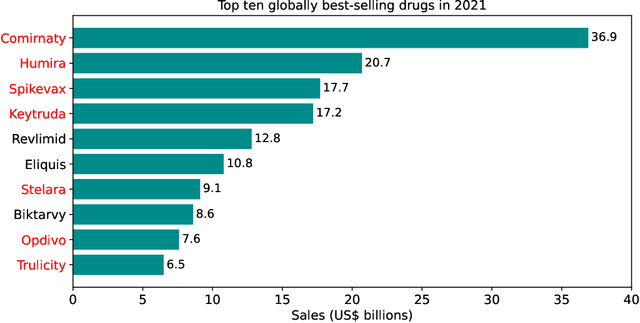

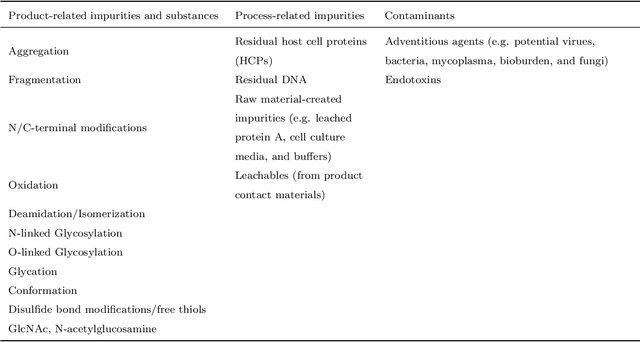

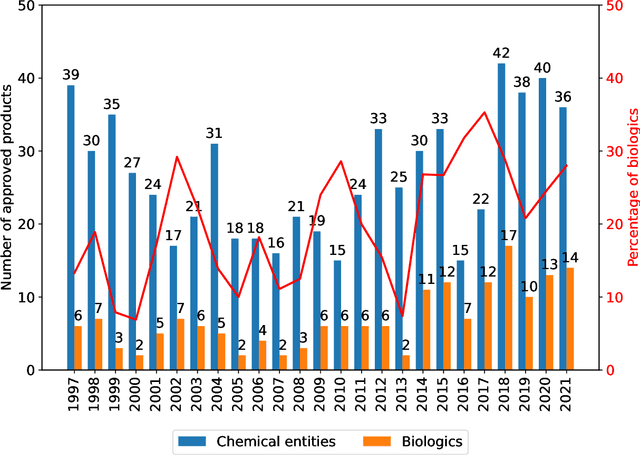

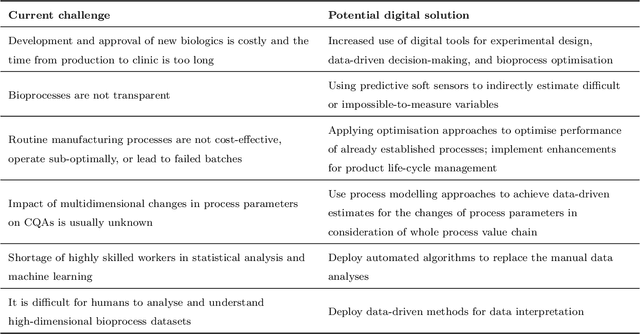

Abstract:While machine learning (ML) has made significant contributions to the biopharmaceutical field, its applications are still in the early stages in terms of providing direct support for quality-by-design based development and manufacturing of biopharmaceuticals, hindering the enormous potential for bioprocesses automation from their development to manufacturing. However, the adoption of ML-based models instead of conventional multivariate data analysis methods is significantly increasing due to the accumulation of large-scale production data. This trend is primarily driven by the real-time monitoring of process variables and quality attributes of biopharmaceutical products through the implementation of advanced process analytical technologies. Given the complexity and multidimensionality of a bioproduct design, bioprocess development, and product manufacturing data, ML-based approaches are increasingly being employed to achieve accurate, flexible, and high-performing predictive models to address the problems of analytics, monitoring, and control within the biopharma field. This paper aims to provide a comprehensive review of the current applications of ML solutions in a bioproduct design, monitoring, control, and optimisation of upstream, downstream, and product formulation processes. Finally, this paper thoroughly discusses the main challenges related to the bioprocesses themselves, process data, and the use of machine learning models in biopharmaceutical process development and manufacturing. Moreover, it offers further insights into the adoption of innovative machine learning methods and novel trends in the development of new digital biopharma solutions.

Multi-fidelity Gaussian Process for Biomanufacturing Process Modeling with Small Data

Nov 26, 2022

Abstract:In biomanufacturing, developing an accurate model to simulate the complex dynamics of bioprocesses is an important yet challenging task. This is partially due to the uncertainty associated with bioprocesses, high data acquisition cost, and lack of data availability to learn complex relations in bioprocesses. To deal with these challenges, we propose to use a statistical machine learning approach, multi-fidelity Gaussian process, for process modelling in biomanufacturing. Gaussian process regression is a well-established technique based on probability theory which can naturally consider uncertainty in a dataset via Gaussian noise, and multi-fidelity techniques can make use of multiple sources of information with different levels of fidelity, thus suitable for bioprocess modeling with small data. We apply the multi-fidelity Gaussian process to solve two significant problems in biomanufacturing, bioreactor scale-up and knowledge transfer across cell lines, and demonstrate its efficacy on real-world datasets.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge