David Zarrouk

Motion Planning for Minimally Actuated Serial Robots

Aug 12, 2024Abstract:Modern manipulators are acclaimed for their precision but often struggle to operate in confined spaces. This limitation has driven the development of hyper-redundant and continuum robots. While these present unique advantages, they face challenges in, for instance, weight, mechanical complexity, modeling and costs. The Minimally Actuated Serial Robot (MASR) has been proposed as a light-weight, low-cost and simpler alternative where passive joints are actuated with a Mobile Actuator (MA) moving along the arm. Yet, Inverse Kinematics (IK) and a general motion planning algorithm for the MASR have not be addressed. In this letter, we propose the MASR-RRT* motion planning algorithm specifically developed for the unique kinematics of MASR. The main component of the algorithm is a data-based model for solving the IK problem while considering minimal traverse of the MA. The model is trained solely using the forward kinematics of the MASR and does not require real data. With the model as a local-connection mechanism, MASR-RRT* minimizes a cost function expressing the action time. In a comprehensive analysis, we show that MASR-RRT* is superior in performance to the straight-forward implementation of the standard RRT*. Experiments on a real robot in different environments with obstacles validate the proposed algorithm.

A Novel Grip Force Measurement Concept for Tactile Stimulation Mechanisms -- Design, Validation, and User Study

Jun 07, 2020

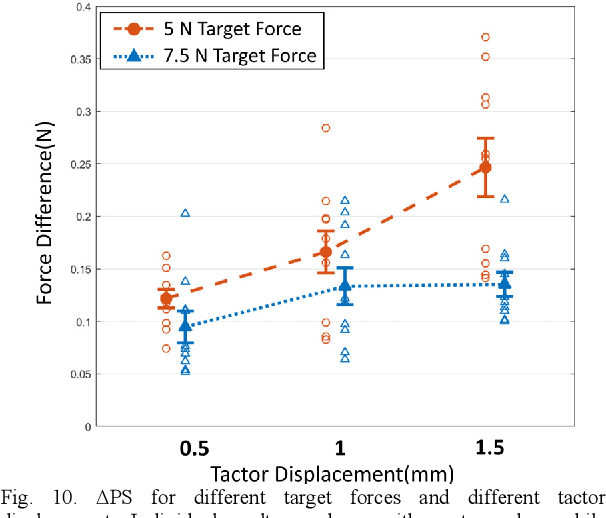

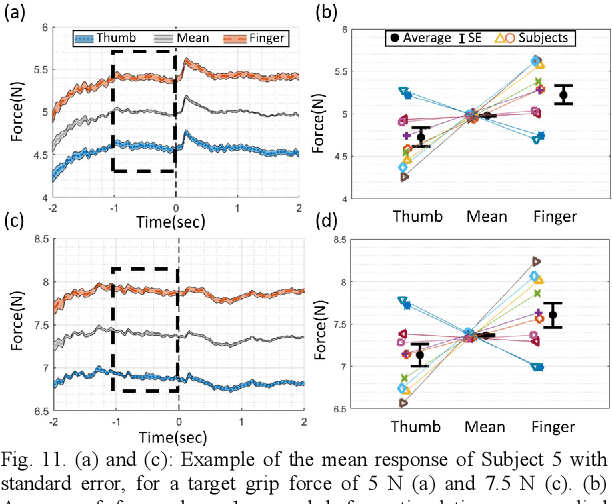

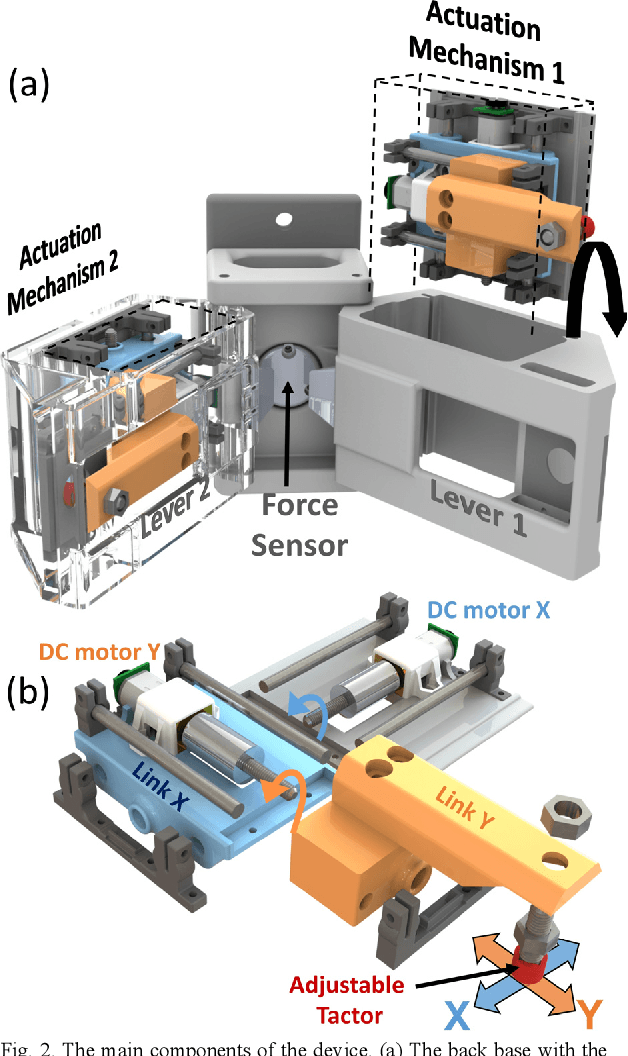

Abstract:We developed a new grip force measurement concept that allows for embedding tactile stimulation mechanisms in a gripper. This concept is based on a single force sensor to measure the force applied on each side of the gripper, and it substantially reduces artifacts of force measurement caused by tactor motion. To test the feasibility of this new concept, we built a device that measures control of grip force in response to a tactile stimulation from a moving tactor. First, we used a custom designed testing setup with a second force sensor to calibrate our device over a range of 0 to 20 N without movement of the tactors. Second, we tested the effect of tactor movement on the measured grip force and measured artifacts of 1% of the measured force. Third, we demonstrated that during the application of dynamically changing grip forces, the average errors were 2.9% and 3.7% for the left and right sides of the gripper, respectively. Finally, we conducted a user study and found that in response to tactor movement, participants increased their grip force, and that the increase was larger for a smaller target force and depended on the amount of tactile stimulation.

Minimally Actuated Serial Robot

May 28, 2017

Abstract:In this paper, we propose a novel type of serial robot with minimal actuation. The robot is a serial rigid structure consisting of multiple links connected by passive joints and of movable actuators. The novelty of this robot is that the actuators travel over the links to a given joint and adjust the relative angle between the two adjacent links. The joints passively preserve their angles until one of the actuators moves them again. This actuation can be applied to any serial robot with two or more links. This unique configuration enables the robot to undergo the same wide range of motions typically associated with hyper-redundant robots but with much fewer actuators. The robot is modular and its size and geometry can be easily changed. We describe the robot's mechanical design and kinematics in detail and demonstrate its capabilities for obstacle avoidance with some simulated examples. In addition, we show how an experimental robot fitted with a single mobile actuator can maneuver through a confined space to reach its target.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge