David P. Fenning

Opportunities for Machine Learning to Accelerate Halide Perovskite Commercialization and Scale-Up

Oct 08, 2021

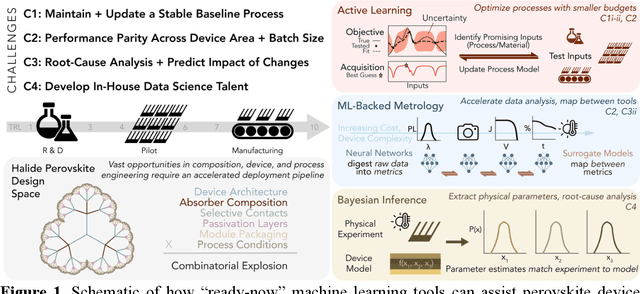

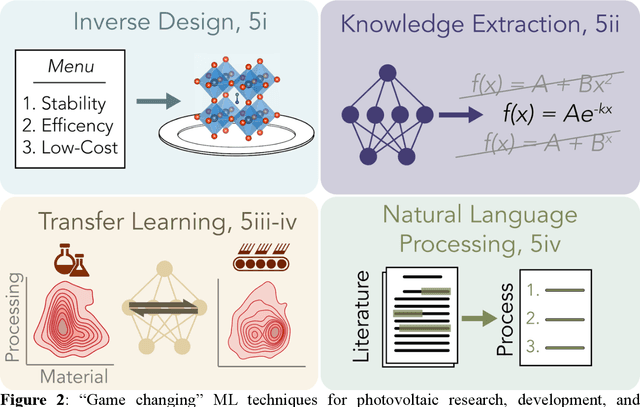

Abstract:While halide perovskites attract significant academic attention, examples of at-scale industrial production are still sparse. In this perspective, we review practical challenges hindering the commercialization of halide perovskites, and discuss how machine-learning (ML) tools could help: (1) active-learning algorithms that blend institutional knowledge and human expertise could help stabilize and rapidly update baseline manufacturing processes; (2) ML-powered metrology, including computer imaging, could help narrow the performance gap between large- and small-area devices; and (3) inference methods could help accelerate root-cause analysis by reconciling multiple data streams and simulations, focusing research effort on areas with highest probability for improvement. We conclude that to satisfy many of these challenges, incremental -- not radical -- adaptations of existing ML and statistical methods are needed. We identify resources to help develop in-house data-science talent, and propose how industry-academic partnerships could help adapt "ready-now" ML tools to specific industry needs, further improve process control by revealing underlying mechanisms, and develop "gamechanger" discovery-oriented algorithms to better navigate vast materials combination spaces and the literature.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge