Daniele Ronzani

Vibration Free Flexible Object Handling with a Robot Manipulator Using Learning Control

Nov 20, 2022Abstract:Many industries extensively use flexible materials. Effective approaches for handling flexible objects with a robot manipulator must address residual vibrations. Existing solutions rely on complex models, use additional instrumentation for sensing the vibrations, or do not exploit the repetitive nature of most industrial tasks. This paper develops an iterative learning control approach that jointly learns model parameters and residual dynamics using only the interoceptive sensors of the robot. The learned model is subsequently utilized to design optimal (PTP) trajectories that accounts for residual vibration, nonlinear kinematics of the manipulator and joint limits. We experimentally show that the proposed approach reduces the residual vibrations by an order of magnitude compared with optimal vibration suppression using the analytical model and threefold compared with the available state-of-the-art method. These results demonstrate that effective handling of a flexible object does not require neither complex models nor additional instrumentation.

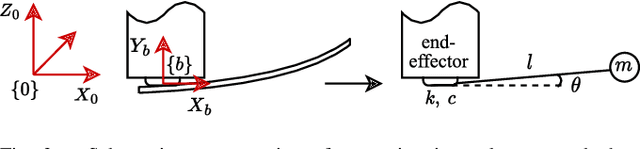

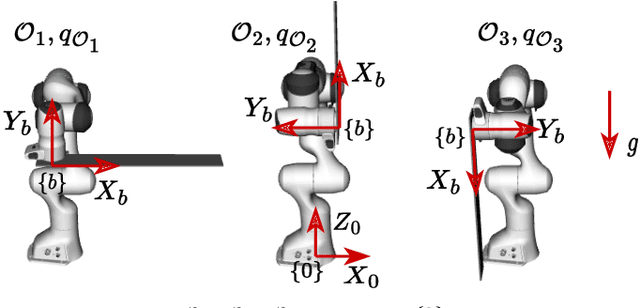

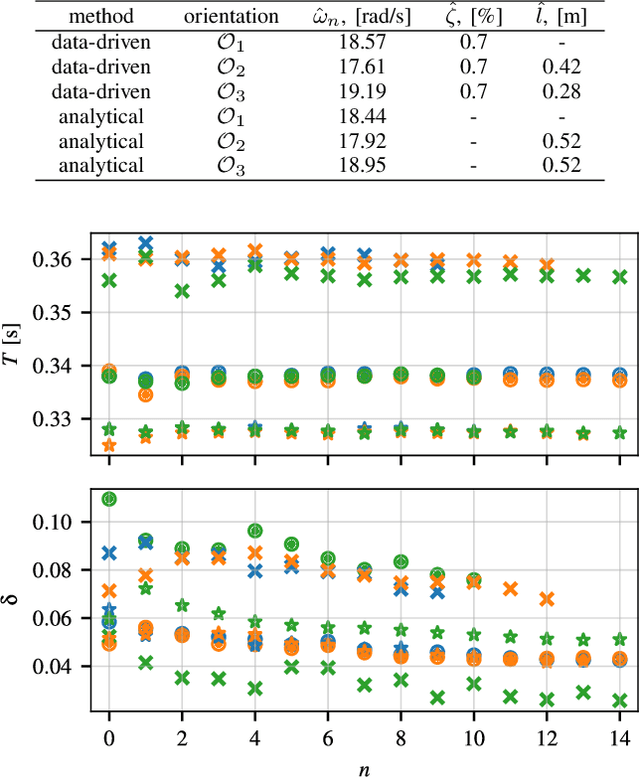

An optimal open-loop strategy for handling a flexible beam with a robot manipulator

Oct 02, 2022

Abstract:Fast and safe manipulation of flexible objects with a robot manipulator necessitates measures to cope with vibrations. Existing approaches either increase the task execution time or require complex models and/or additional instrumentation to measure vibrations. This paper develops a model-based method that overcomes these limitations. It relies on a simple pendulum-like model for modeling the beam, open-loop optimal control for suppressing vibrations, and does not require any exteroceptive sensors. We experimentally show that the proposed method drastically reduces residual vibrations -- at least 90% -- and outperforms the commonly used input shaping (IS) for the same execution time. Besides, our method can also execute the task faster than IS with a minor reduction in vibration suppression performance. The proposed method facilitates the development of new solutions to a wide range of tasks that involve dynamic manipulation of flexible objects.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge