Daniel Grünbaum

Management Decisions in Manufacturing using Causal Machine Learning -- To Rework, or not to Rework?

Jun 17, 2024

Abstract:In this paper, we present a data-driven model for estimating optimal rework policies in manufacturing systems. We consider a single production stage within a multistage, lot-based system that allows for optional rework steps. While the rework decision depends on an intermediate state of the lot and system, the final product inspection, and thus the assessment of the actual yield, is delayed until production is complete. Repair steps are applied uniformly to the lot, potentially improving some of the individual items while degrading others. The challenge is thus to balance potential yield improvement with the rework costs incurred. Given the inherently causal nature of this decision problem, we propose a causal model to estimate yield improvement. We apply methods from causal machine learning, in particular double/debiased machine learning (DML) techniques, to estimate conditional treatment effects from data and derive policies for rework decisions. We validate our decision model using real-world data from opto-electronic semiconductor manufacturing, achieving a yield improvement of 2 - 3% during the color-conversion process of white light-emitting diodes (LEDs).

Causally Learning an Optimal Rework Policy

Jun 07, 2023

Abstract:In manufacturing, rework refers to an optional step of a production process which aims to eliminate errors or remedy products that do not meet the desired quality standards. Reworking a production lot involves repeating a previous production stage with adjustments to ensure that the final product meets the required specifications. While offering the chance to improve the yield and thus increase the revenue of a production lot, a rework step also incurs additional costs. Additionally, the rework of parts that already meet the target specifications may damage them and decrease the yield. In this paper, we apply double/debiased machine learning (DML) to estimate the conditional treatment effect of a rework step during the color conversion process in opto-electronic semiconductor manufacturing on the final product yield. We utilize the implementation DoubleML to develop policies for the rework of components and estimate their value empirically. From our causal machine learning analysis we derive implications for the coating of monochromatic LEDs with conversion layers.

Quantitative probing: Validating causal models using quantitative domain knowledge

Sep 07, 2022

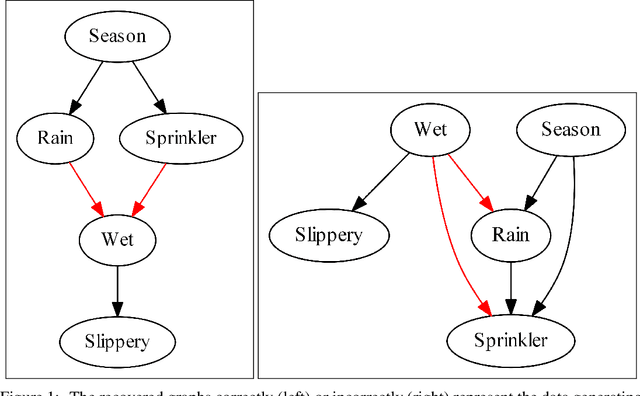

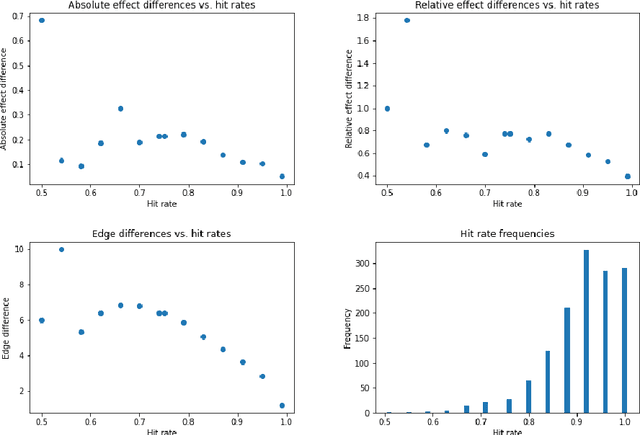

Abstract:We present quantitative probing as a model-agnostic framework for validating causal models in the presence of quantitative domain knowledge. The method is constructed as an analogue of the train/test split in correlation-based machine learning and as an enhancement of current causal validation strategies that are consistent with the logic of scientific discovery. The effectiveness of the method is illustrated using Pearl's sprinkler example, before a thorough simulation-based investigation is conducted. Limits of the technique are identified by studying exemplary failing scenarios, which are furthermore used to propose a list of topics for future research and improvements of the presented version of quantitative probing. The code for integrating quantitative probing into causal analysis, as well as the code for the presented simulation-based studies of the effectiveness of quantitative probing is provided in two separate open-source Python packages.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge