Chandula T. Wickramarachchi

Active learning for regression in engineering populations: A risk-informed approach

Sep 06, 2024

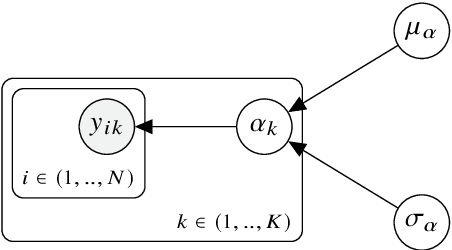

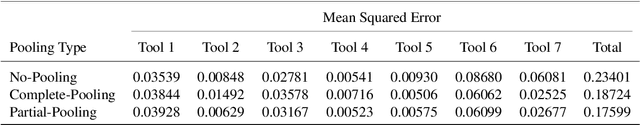

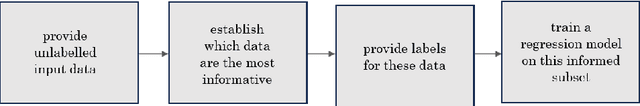

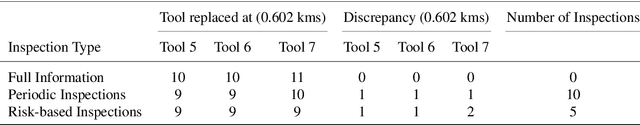

Abstract:Regression is a fundamental prediction task common in data-centric engineering applications that involves learning mappings between continuous variables. In many engineering applications (e.g.\ structural health monitoring), feature-label pairs used to learn such mappings are of limited availability which hinders the effectiveness of traditional supervised machine learning approaches. The current paper proposes a methodology for overcoming the issue of data scarcity by combining active learning with hierarchical Bayesian modelling. Active learning is an approach for preferentially acquiring feature-label pairs in a resource-efficient manner. In particular, the current work adopts a risk-informed approach that leverages contextual information associated with regression-based engineering decision-making tasks (e.g.\ inspection and maintenance). Hierarchical Bayesian modelling allow multiple related regression tasks to be learned over a population, capturing local and global effects. The information sharing facilitated by this modelling approach means that information acquired for one engineering system can improve predictive performance across the population. The proposed methodology is demonstrated using an experimental case study. Specifically, multiple regressions are performed over a population of machining tools, where the quantity of interest is the surface roughness of the workpieces. An inspection and maintenance decision process is defined using these regression tasks which is in turn used to construct the active-learning algorithm. The novel methodology proposed is benchmarked against an uninformed approach to label acquisition and independent modelling of the regression tasks. It is shown that the proposed approach has superior performance in terms of expected cost -- maintaining predictive performance while reducing the number of inspections required.

Sharing Information Between Machine Tools to Improve Surface Finish Forecasting

Oct 09, 2023Abstract:At present, most surface-quality prediction methods can only perform single-task prediction which results in under-utilised datasets, repetitive work and increased experimental costs. To counter this, the authors propose a Bayesian hierarchical model to predict surface-roughness measurements for a turning machining process. The hierarchical model is compared to multiple independent Bayesian linear regression models to showcase the benefits of partial pooling in a machining setting with respect to prediction accuracy and uncertainty quantification.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge