Bryce Doerr

The ReSWARM Microgravity Flight Experiments: Planning, Control, and Model Estimation for On-Orbit Close Proximity Operations

Jan 03, 2023Abstract:On-orbit close proximity operations involve robotic spacecraft maneuvering and making decisions for a growing number of mission scenarios demanding autonomy, including on-orbit assembly, repair, and astronaut assistance. Of these scenarios, on-orbit assembly is an enabling technology that will allow large space structures to be built in-situ, using smaller building block modules. However, robotic on-orbit assembly involves a number of technical hurdles such as changing system models. For instance, grappled modules moved by a free-flying "assembler" robot can cause significant shifts in system inertial properties, which has cascading impacts on motion planning and control portions of the autonomy stack. Further, on-orbit assembly and other scenarios require collision-avoiding motion planning, particularly when operating in a "construction site" scenario of multiple assembler robots and structures. These complicating factors, relevant to many autonomous microgravity robotics use cases, are tackled in the ReSWARM flight experiments as a set of tests on the International Space Station using NASA's Astrobee robots. RElative Satellite sWarming and Robotic Maneuvering, or ReSWARM, demonstrates multiple key technologies for close proximity operations and on-orbit assembly: (1) global long-horizon planning, accomplished using offline and online sampling-based planner options that consider the system dynamics; (2) on-orbit reconfiguration model learning, using the recently-proposed RATTLE information-aware planning framework; and (3) robust control tools to provide low-level control robustness using current system knowledge. These approaches are detailed individually and in an "on-orbit assembly scenario" of multi-waypoint tracking on-orbit. Additionally, detail is provided discussing the practicalities of hardware implementation and unique aspects of working with Astrobee in microgravity.

Safe and Uncertainty-Aware Robotic Motion Planning Techniques for Agile On-Orbit Assembly

Feb 20, 2021

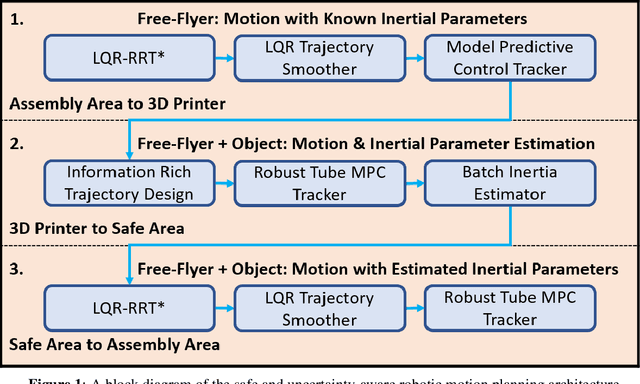

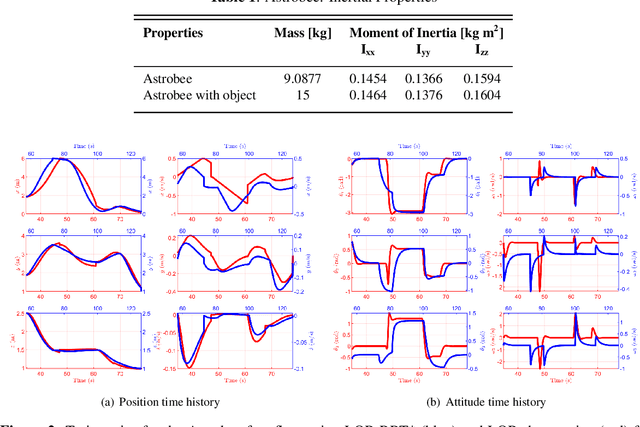

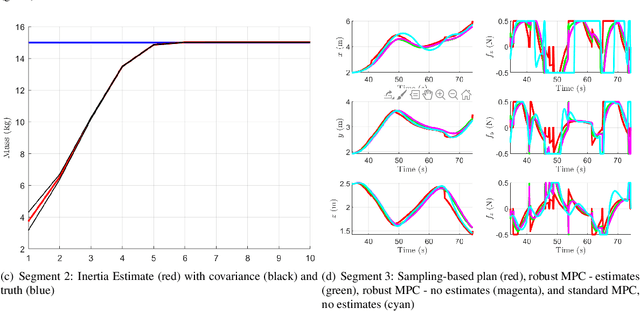

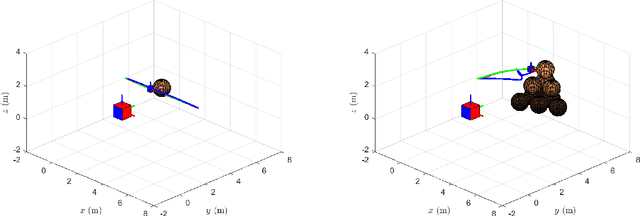

Abstract:As access to space and robotic autonomy capabilities move forward, there is simultaneously a growing interest in deploying large, complex space structures to provide new on-orbit capabilities. New space-borne observatories, large orbital outposts, and even futuristic on-orbit manufacturing will be enabled by robotic assembly of space structures using techniques like on-orbit additive manufacturing which can provide flexibility in constructing and even repairing complex hardware. However, the dynamics underlying the robotic assembler during manipulation may operate under inertial uncertainties. Thus, inertial estimation of the robot and the manipulated component system must be considered during structural assembly. The contribution of this work is to address both the motion planning and control for robotic assembly with consideration of the inertial estimation of the combined free-flying robotic assembler and additively manufactured component system. Specifically, the Linear Quadratic Regulator Rapidly-Exploring Randomized Trees (LQR-RRT*) and dynamically feasible path smoothing are used to obtain obstacle-free trajectories for the system. Further, model learning is incorporated explicitly into the planning stages via approximation of the continuous system and accompanying reward of performing safe, objective-oriented motion. Remaining uncertainty can then be dealt with using robust tube model predictive control. By obtaining controlled trajectories that consider both obstacle avoidance and learning of the inertial properties of the free-flyer and manipulated component system, the free-flyer rapidly considers and plans the construction of space structures with enhanced system knowledge. The approach naturally generalizes to repairing, refueling, and re-provisioning space structure components while providing optimal collision-free trajectories under e.g., inertial uncertainty.

Motion Planning and Control for On-Orbit Assembly using LQR-RRT* and Nonlinear MPC

Aug 06, 2020Abstract:Deploying large, complex space structures is of great interest to the modern scientific world as it can provide new capabilities in obtaining scientific, communicative, and observational information. However, many theoretical mission designs contain complexities that must be constrained by the requirements of the launch vehicle, such as volume and mass. To mitigate such constraints, the use of on-orbit additive manufacturing and robotic assembly allows for the flexibility of building large complex structures including telescopes, space stations, and communication satellites. The contribution of this work is to develop motion planning and control algorithms using the linear quadratic regulator and rapidly-exploring randomized trees (LQR-RRT*), path smoothing, and tracking the trajectory using a closed-loop nonlinear receding horizon control optimizer for a robotic Astrobee free-flyer. By obtaining controlled trajectories that consider obstacle avoidance and dynamics of the vehicle and manipulator, the free-flyer rapidly considers and plans the construction of space structures. The approach is a natural generalization to repairing, refueling, and re-provisioning space structure components while providing optimal collision-free trajectories during operation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge