Binil Starly

Evaluating Deep Clustering Algorithms on Non-Categorical 3D CAD Models

Apr 29, 2024

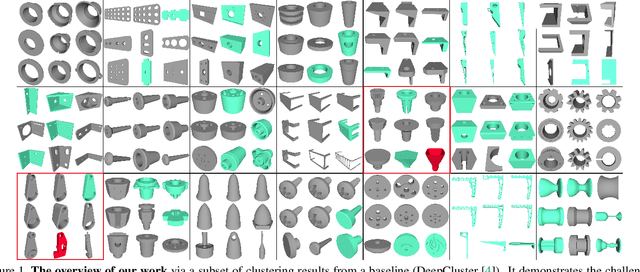

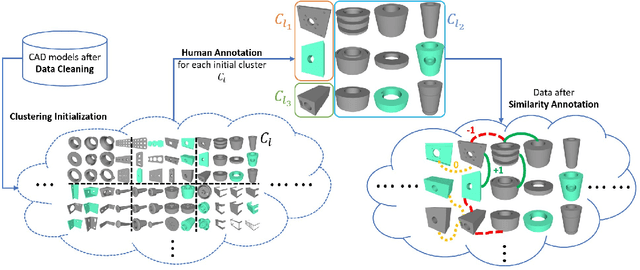

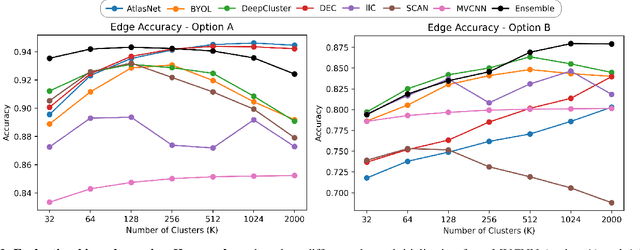

Abstract:We introduce the first work on benchmarking and evaluating deep clustering algorithms on large-scale non-categorical 3D CAD models. We first propose a workflow to allow expert mechanical engineers to efficiently annotate 252,648 carefully sampled pairwise CAD model similarities, from a subset of the ABC dataset with 22,968 shapes. Using seven baseline deep clustering methods, we then investigate the fundamental challenges of evaluating clustering methods for non-categorical data. Based on these challenges, we propose a novel and viable ensemble-based clustering comparison approach. This work is the first to directly target the underexplored area of deep clustering algorithms for 3D shapes, and we believe it will be an important building block to analyze and utilize the massive 3D shape collections that are starting to appear in deep geometric computing.

Building A Knowledge Graph to Enrich ChatGPT Responses in Manufacturing Service Discovery

Apr 09, 2024

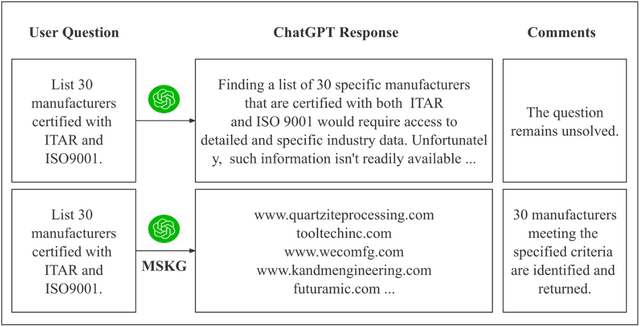

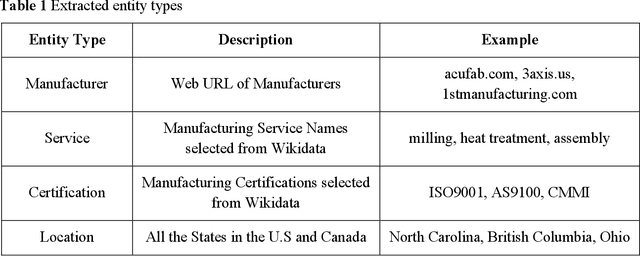

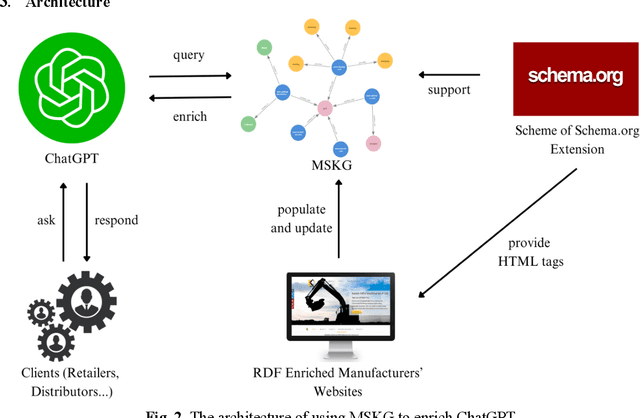

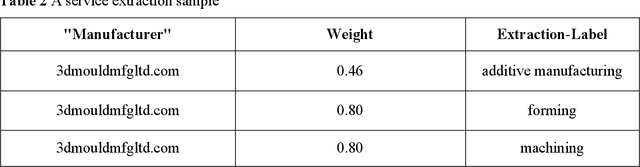

Abstract:Sourcing and identification of new manufacturing partners is crucial for manufacturing system integrators to enhance agility and reduce risk through supply chain diversification in the global economy. The advent of advanced large language models has captured significant interest, due to their ability to generate comprehensive and articulate responses across a wide range of knowledge domains. However, the system often falls short in accuracy and completeness when responding to domain-specific inquiries, particularly in areas like manufacturing service discovery. This research explores the potential of leveraging Knowledge Graphs in conjunction with ChatGPT to streamline the process for prospective clients in identifying small manufacturing enterprises. In this study, we propose a method that integrates bottom-up ontology with advanced machine learning models to develop a Manufacturing Service Knowledge Graph from an array of structured and unstructured data sources, including the digital footprints of small-scale manufacturers throughout North America. The Knowledge Graph and the learned graph embedding vectors are leveraged to tackle intricate queries within the digital supply chain network, responding with enhanced reliability and greater interpretability. The approach highlighted is scalable to millions of entities that can be distributed to form a global Manufacturing Service Knowledge Network Graph that can potentially interconnect multiple types of Knowledge Graphs that span industry sectors, geopolitical boundaries, and business domains. The dataset developed for this study, now publicly accessible, encompasses more than 13,000 manufacturers' weblinks, manufacturing services, certifications, and location entity types.

Manufacturing Service Capability Prediction with Graph Neural Networks

Mar 25, 2024Abstract:In the current landscape, the predominant methods for identifying manufacturing capabilities from manufacturers rely heavily on keyword matching and semantic matching. However, these methods often fall short by either overlooking valuable hidden information or misinterpreting critical data. Consequently, such approaches result in an incomplete identification of manufacturers' capabilities. This underscores the pressing need for data-driven solutions to enhance the accuracy and completeness of manufacturing capability identification. To address the need, this study proposes a Graph Neural Network-based method for manufacturing service capability identification over a knowledge graph. To enhance the identification performance, this work introduces a novel approach that involves aggregating information from the graph nodes' neighborhoods as well as oversampling the graph data, which can be effectively applied across a wide range of practical scenarios. Evaluations conducted on a Manufacturing Service Knowledge Graph and subsequent ablation studies demonstrate the efficacy and robustness of the proposed approach. This study not only contributes a innovative method for inferring manufacturing service capabilities but also significantly augments the quality of Manufacturing Service Knowledge Graphs.

Research Directions in Democratizing Innovation through Design Automation, One-Click Manufacturing Services and Intelligent Machines

Sep 23, 2019

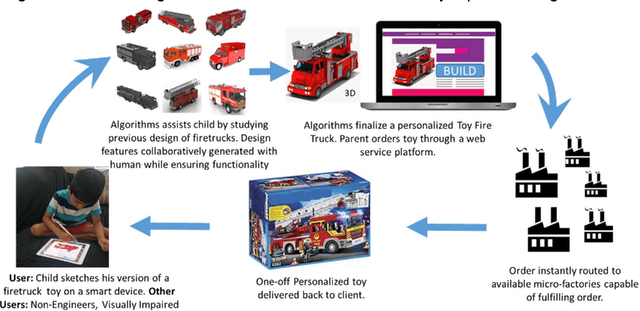

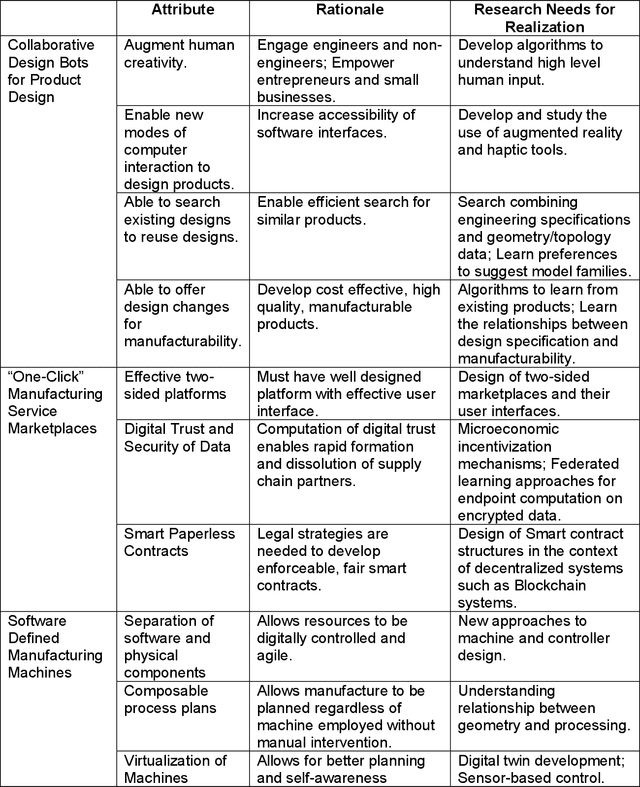

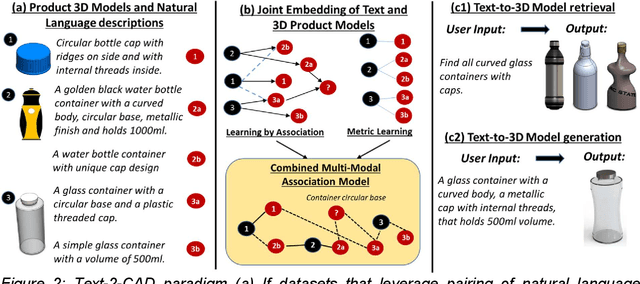

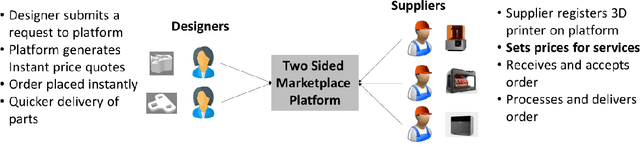

Abstract:The digitalization of manufacturing has created opportunities for consumers to customize products that fit their individualized needs which in turn would drive demand for manufacturing services. However, this pull-based manufacturing system production of extremely low quantity and limitless variety for products is expensive to implement. New emerging technology in design automation driven by data-driven computational design, manufacturing-as-a-service marketplaces and digitally enabled micro-factories holds promise towards democratization of innovation. In this paper, scientific, technology and infrastructure challenges are identified and if solved, the impact of these emerging technologies on product innovation and future factory organization is discussed.

Network Based Pricing for 3D Printing Services in Two-Sided Manufacturing-as-a-Service Marketplace

Jul 17, 2019

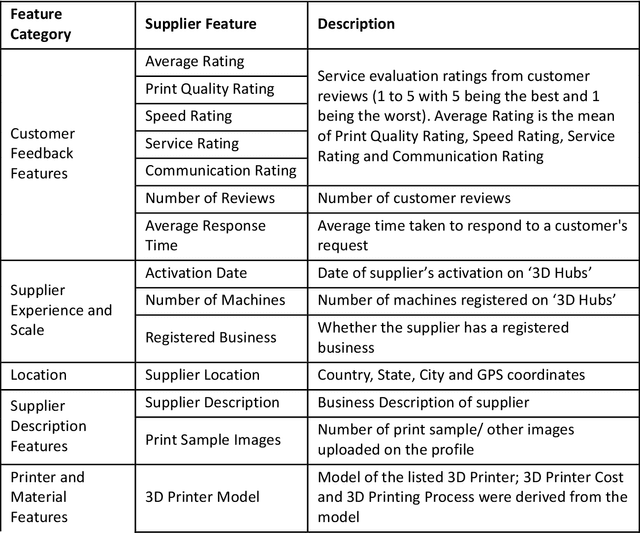

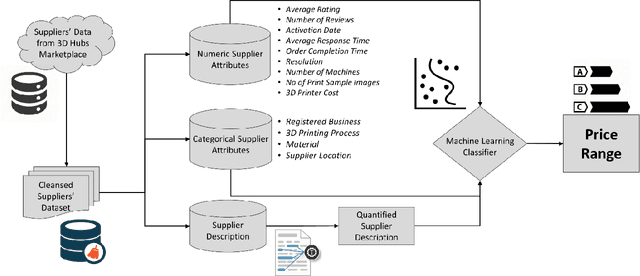

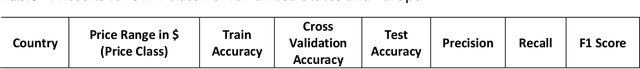

Abstract:This paper presents approaches to determine a network based pricing for 3D printing services in the context of a two-sided manufacturing-as-a-service marketplace. The intent is to provide cost analytics to enable service bureaus to better compete in the market by moving away from setting ad-hoc and subjective prices. A data mining approach with machine learning methods is used to estimate a price range based on the profile characteristics of 3D printing service suppliers. The model considers factors such as supplier experience, supplier capabilities, customer reviews and ratings from past orders, and scale of operations among others to estimate a price range for suppliers' services. Data was gathered from existing marketplace websites, which was then used to train and test the model. The model demonstrates an accuracy of 65% for US based suppliers and 59% for Europe based suppliers to classify a supplier's 3D Printer listing in one of the seven price categories. The improvement over baseline accuracy of 25% demonstrates that machine learning based methods are promising for network based pricing in manufacturing marketplaces. Conventional methodologies for pricing services through activity based costing are inefficient in strategically pricing 3D printing service offering in a connected marketplace. As opposed to arbitrarily determining prices, this work proposes an approach to determine prices through data mining methods to estimate competitive prices. Such tools can be built into online marketplaces to help independent service bureaus to determine service price rates.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge