Ahmad Moeineddin

Finite Operator Learning: Bridging Neural Operators and Numerical Methods for Efficient Parametric Solution and Optimization of PDEs

Jul 04, 2024

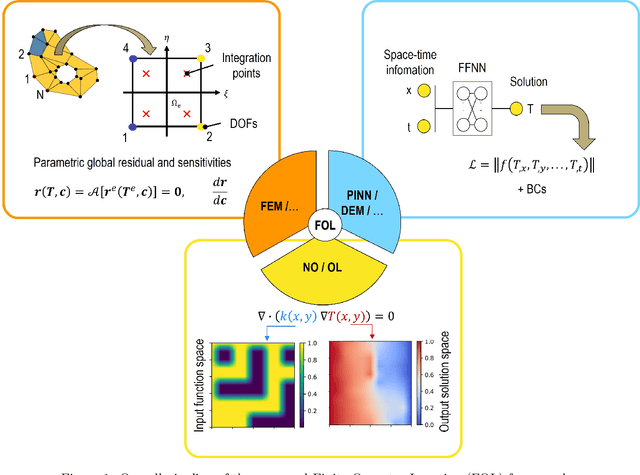

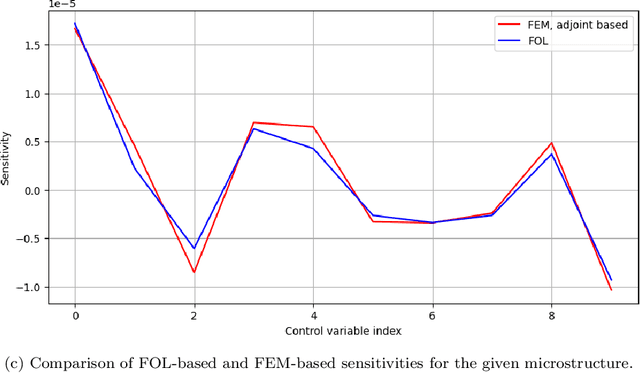

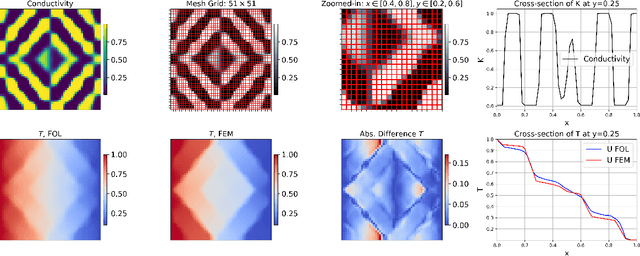

Abstract:We introduce a method that combines neural operators, physics-informed machine learning, and standard numerical methods for solving PDEs. The proposed approach extends each of the aforementioned methods and unifies them within a single framework. We can parametrically solve partial differential equations in a data-free manner and provide accurate sensitivities, meaning the derivatives of the solution space with respect to the design space. These capabilities enable gradient-based optimization without the typical sensitivity analysis costs, unlike adjoint methods that scale directly with the number of response functions. Our Finite Operator Learning (FOL) approach uses an uncomplicated feed-forward neural network model to directly map the discrete design space (i.e. parametric input space) to the discrete solution space (i.e. finite number of sensor points in the arbitrary shape domain) ensuring compliance with physical laws by designing them into loss functions. The discretized governing equations, as well as the design and solution spaces, can be derived from any well-established numerical techniques. In this work, we employ the Finite Element Method (FEM) to approximate fields and their spatial derivatives. Subsequently, we conduct Sobolev training to minimize a multi-objective loss function, which includes the discretized weak form of the energy functional, boundary conditions violations, and the stationarity of the residuals with respect to the design variables. Our study focuses on the steady-state heat equation within heterogeneous materials that exhibits significant phase contrast and possibly temperature-dependent conductivity. The network's tangent matrix is directly used for gradient-based optimization to improve the microstructure's heat transfer characteristics. ...

Integration of physics-informed operator learning and finite element method for parametric learning of partial differential equations

Jan 04, 2024Abstract:We present a method that employs physics-informed deep learning techniques for parametrically solving partial differential equations. The focus is on the steady-state heat equations within heterogeneous solids exhibiting significant phase contrast. Similar equations manifest in diverse applications like chemical diffusion, electrostatics, and Darcy flow. The neural network aims to establish the link between the complex thermal conductivity profiles and temperature distributions, as well as heat flux components within the microstructure, under fixed boundary conditions. A distinctive aspect is our independence from classical solvers like finite element methods for data. A noteworthy contribution lies in our novel approach to defining the loss function, based on the discretized weak form of the governing equation. This not only reduces the required order of derivatives but also eliminates the need for automatic differentiation in the construction of loss terms, accepting potential numerical errors from the chosen discretization method. As a result, the loss function in this work is an algebraic equation that significantly enhances training efficiency. We benchmark our methodology against the standard finite element method, demonstrating accurate yet faster predictions using the trained neural network for temperature and flux profiles. We also show higher accuracy by using the proposed method compared to purely data-driven approaches for unforeseen scenarios.

Learning solution of nonlinear constitutive material models using physics-informed neural networks: COMM-PINN

Apr 10, 2023Abstract:We applied physics-informed neural networks to solve the constitutive relations for nonlinear, path-dependent material behavior. As a result, the trained network not only satisfies all thermodynamic constraints but also instantly provides information about the current material state (i.e., free energy, stress, and the evolution of internal variables) under any given loading scenario without requiring initial data. One advantage of this work is that it bypasses the repetitive Newton iterations needed to solve nonlinear equations in complex material models. Additionally, strategies are provided to reduce the required order of derivation for obtaining the tangent operator. The trained model can be directly used in any finite element package (or other numerical methods) as a user-defined material model. However, challenges remain in the proper definition of collocation points and in integrating several non-equality constraints that become active or non-active simultaneously. We tested this methodology on rate-independent processes such as the classical von Mises plasticity model with a nonlinear hardening law, as well as local damage models for interface cracking behavior with a nonlinear softening law. Finally, we discuss the potential and remaining challenges for future developments of this new approach.

Mixed formulation of physics-informed neural networks for thermo-mechanically coupled systems and heterogeneous domains

Feb 09, 2023Abstract:Deep learning methods find a solution to a boundary value problem by defining loss functions of neural networks based on governing equations, boundary conditions, and initial conditions. Furthermore, the authors show that when it comes to many engineering problems, designing the loss functions based on first-order derivatives results in much better accuracy, especially when there is heterogeneity and variable jumps in the domain \cite{REZAEI2022PINN}. The so-called mixed formulation for PINN is applied to basic engineering problems such as the balance of linear momentum and diffusion problems. In this work, the proposed mixed formulation is further extended to solve multi-physical problems. In particular, we focus on a stationary thermo-mechanically coupled system of equations that can be utilized in designing the microstructure of advanced materials. First, sequential unsupervised training, and second, fully coupled unsupervised learning are discussed. The results of each approach are compared in terms of accuracy and corresponding computational cost. Finally, the idea of transfer learning is employed by combining data and physics to address the capability of the network to predict the response of the system for unseen cases. The outcome of this work will be useful for many other engineering applications where DL is employed on multiple coupled systems of equations.

A mixed formulation for physics-informed neural networks as a potential solver for engineering problems in heterogeneous domains: comparison with finite element method

Jun 27, 2022

Abstract:Physics-informed neural networks (PINNs) are capable of finding the solution for a given boundary value problem. We employ several ideas from the finite element method (FEM) to enhance the performance of existing PINNs in engineering problems. The main contribution of the current work is to promote using the spatial gradient of the primary variable as an output from separated neural networks. Later on, the strong form which has a higher order of derivatives is applied to the spatial gradients of the primary variable as the physical constraint. In addition, the so-called energy form of the problem is applied to the primary variable as an additional constraint for training. The proposed approach only required up to first-order derivatives to construct the physical loss functions. We discuss why this point is beneficial through various comparisons between different models. The mixed formulation-based PINNs and FE methods share some similarities. While the former minimizes the PDE and its energy form at given collocation points utilizing a complex nonlinear interpolation through a neural network, the latter does the same at element nodes with the help of shape functions. We focus on heterogeneous solids to show the capability of deep learning for predicting the solution in a complex environment under different boundary conditions. The performance of the proposed PINN model is checked against the solution from FEM on two prototype problems: elasticity and the Poisson equation (steady-state diffusion problem). We concluded that by properly designing the network architecture in PINN, the deep learning model has the potential to solve the unknowns in a heterogeneous domain without any available initial data from other sources. Finally, discussions are provided on the combination of PINN and FEM for a fast and accurate design of composite materials in future developments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge