Abdellatif Bey-Temsamani

A Comparative Study of 3D Model Acquisition Methods for Synthetic Data Generation of Agricultural Products

Jan 07, 2026Abstract:In the manufacturing industry, computer vision systems based on artificial intelligence (AI) are widely used to reduce costs and increase production. Training these AI models requires a large amount of training data that is costly to acquire and annotate, especially in high-variance, low-volume manufacturing environments. A popular approach to reduce the need for real data is the use of synthetic data that is generated by leveraging computer-aided design (CAD) models available in the industry. However, in the agricultural industry these models are not readily available, increasing the difficulty in leveraging synthetic data. In this paper, we present different techniques for substituting CAD files to create synthetic datasets. We measure their relative performance when used to train an AI object detection model to separate stones and potatoes in a bin picking environment. We demonstrate that using highly representative 3D models acquired by scanning or using image-to-3D approaches can be used to generate synthetic data for training object detection models. Finetuning on a small real dataset can significantly improve the performance of the models and even get similar performance when less representative models are used.

Privacy-Preserving Computer Vision for Industry: Three Case Studies in Human-Centric Manufacturing

Dec 10, 2025Abstract:The adoption of AI-powered computer vision in industry is often constrained by the need to balance operational utility with worker privacy. Building on our previously proposed privacy-preserving framework, this paper presents its first comprehensive validation on real-world data collected directly by industrial partners in active production environments. We evaluate the framework across three representative use cases: woodworking production monitoring, human-aware AGV navigation, and multi-camera ergonomic risk assessment. The approach employs learned visual transformations that obscure sensitive or task-irrelevant information while retaining features essential for task performance. Through both quantitative evaluation of the privacy-utility trade-off and qualitative feedback from industrial partners, we assess the framework's effectiveness, deployment feasibility, and trust implications. Results demonstrate that task-specific obfuscation enables effective monitoring with reduced privacy risks, establishing the framework's readiness for real-world adoption and providing cross-domain recommendations for responsible, human-centric AI deployment in industry.

Enabling Privacy-Aware AI-Based Ergonomic Analysis

May 12, 2025Abstract:Musculoskeletal disorders (MSDs) are a leading cause of injury and productivity loss in the manufacturing industry, incurring substantial economic costs. Ergonomic assessments can mitigate these risks by identifying workplace adjustments that improve posture and reduce strain. Camera-based systems offer a non-intrusive, cost-effective method for continuous ergonomic tracking, but they also raise significant privacy concerns. To address this, we propose a privacy-aware ergonomic assessment framework utilizing machine learning techniques. Our approach employs adversarial training to develop a lightweight neural network that obfuscates video data, preserving only the essential information needed for human pose estimation. This obfuscation ensures compatibility with standard pose estimation algorithms, maintaining high accuracy while protecting privacy. The obfuscated video data is transmitted to a central server, where state-of-the-art keypoint detection algorithms extract body landmarks. Using multi-view integration, 3D keypoints are reconstructed and evaluated with the Rapid Entire Body Assessment (REBA) method. Our system provides a secure, effective solution for ergonomic monitoring in industrial environments, addressing both privacy and workplace safety concerns.

CAD2Render: A Modular Toolkit for GPU-accelerated Photorealistic Synthetic Data Generation for the Manufacturing Industry

Nov 25, 2022Abstract:The use of computer vision for product and assembly quality control is becoming ubiquitous in the manufacturing industry. Lately, it is apparent that machine learning based solutions are outperforming classical computer vision algorithms in terms of performance and robustness. However, a main drawback is that they require sufficiently large and labeled training datasets, which are often not available or too tedious and too time consuming to acquire. This is especially true for low-volume and high-variance manufacturing. Fortunately, in this industry, CAD models of the manufactured or assembled products are available. This paper introduces CAD2Render, a GPU-accelerated synthetic data generator based on the Unity High Definition Render Pipeline (HDRP). CAD2Render is designed to add variations in a modular fashion, making it possible for high customizable data generation, tailored to the needs of the industrial use case at hand. Although CAD2Render is specifically designed for manufacturing use cases, it can be used for other domains as well. We validate CAD2Render by demonstrating state of the art performance in two industrial relevant setups. We demonstrate that the data generated by our approach can be used to train object detection and pose estimation models with a high enough accuracy to direct a robot. The code for CAD2Render is available at https://github.com/EDM-Research/CAD2Render.

Embedded Line Scan Image Sensors: The Low Cost Alternative for High Speed Imaging

Dec 07, 2016

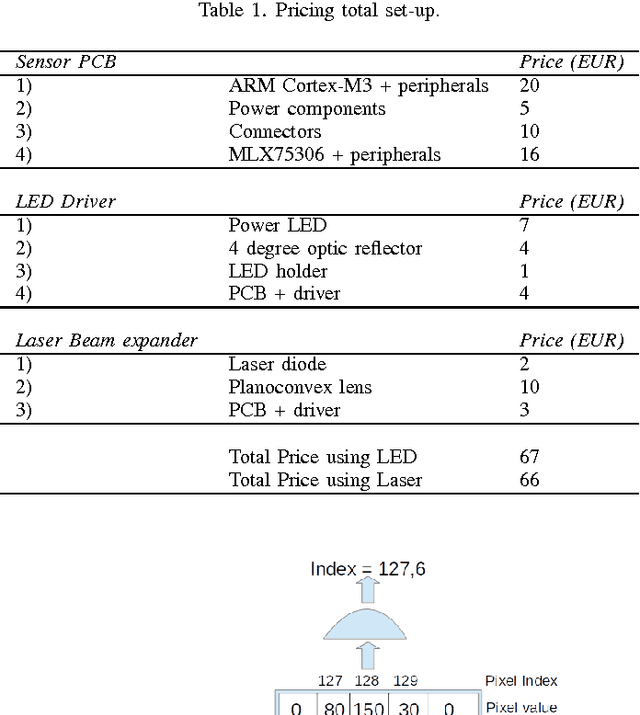

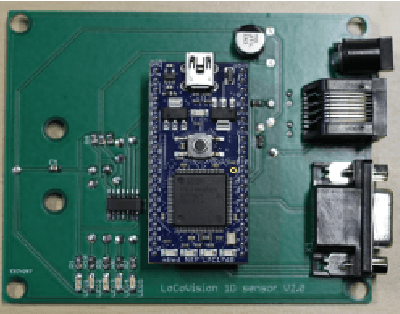

Abstract:In this paper we propose a low-cost high-speed imaging line scan system. We replace an expensive industrial line scan camera and illumination with a custom-built set-up of cheap off-the-shelf components, yielding a measurement system with comparative quality while costing about 20 times less. We use a low-cost linear (1D) image sensor, cheap optics including a LED-based or LASER-based lighting and an embedded platform to process the images. A step-by-step method to design such a custom high speed imaging system and select proper components is proposed. Simulations allowing to predict the final image quality to be obtained by the set-up has been developed. Finally, we applied our method in a lab, closely representing the real-life cases. Our results shows that our simulations are very accurate and that our low-cost line scan set-up acquired image quality compared to the high-end commercial vision system, for a fraction of the price.

* 2015 International Conference on Image Processing Theory, Tools and Applications (IPTA)

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge