On The Reliability Of Machine Learning Applications In Manufacturing Environments

Paper and Code

Dec 19, 2021

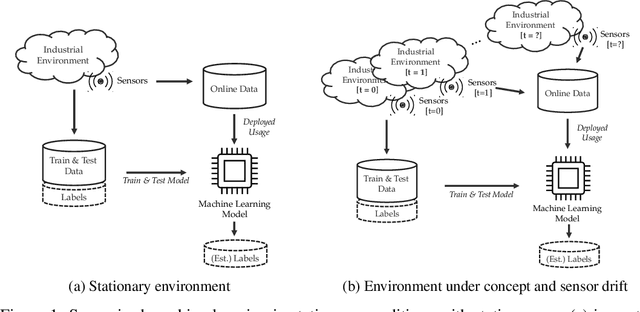

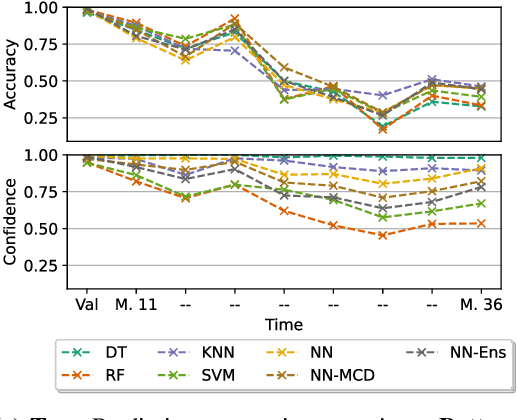

The increasing deployment of advanced digital technologies such as Internet of Things (IoT) devices and Cyber-Physical Systems (CPS) in industrial environments is enabling the productive use of machine learning (ML) algorithms in the manufacturing domain. As ML applications transcend from research to productive use in real-world industrial environments, the question of reliability arises. Since the majority of ML models are trained and evaluated on static datasets, continuous online monitoring of their performance is required to build reliable systems. Furthermore, concept and sensor drift can lead to degrading accuracy of the algorithm over time, thus compromising safety, acceptance and economics if undetected and not properly addressed. In this work, we exemplarily highlight the severity of the issue on a publicly available industrial dataset which was recorded over the course of 36 months and explain possible sources of drift. We assess the robustness of ML algorithms commonly used in manufacturing and show, that the accuracy strongly declines with increasing drift for all tested algorithms. We further investigate how uncertainty estimation may be leveraged for online performance estimation as well as drift detection as a first step towards continually learning applications. The results indicate, that ensemble algorithms like random forests show the least decay of confidence calibration under drift.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge