Neuromorphic Vision Based Control for the Precise Positioning of Robotic Drilling Systems

Paper and Code

Jan 05, 2022

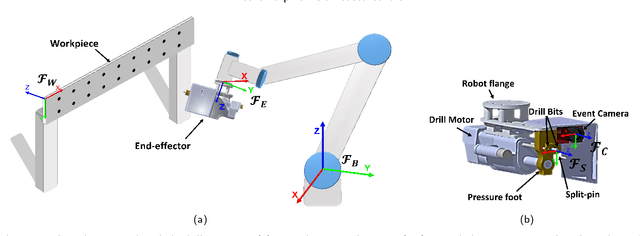

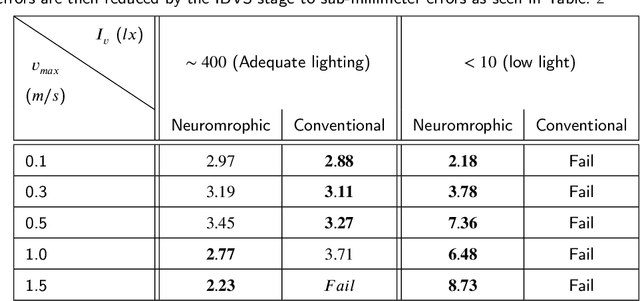

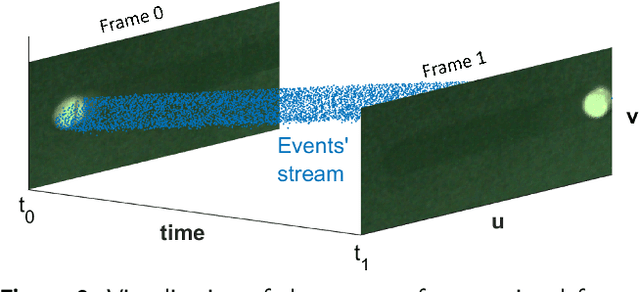

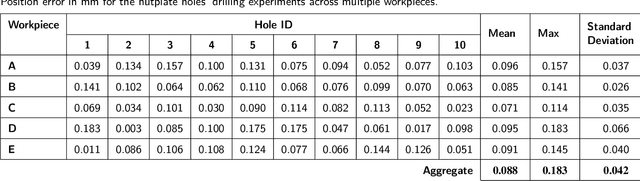

The manufacturing industry is currently witnessing a paradigm shift with the unprecedented adoption of industrial robots, and machine vision is a key perception technology that enables these robots to perform precise operations in unstructured environments. However, the sensitivity of conventional vision sensors to lighting conditions and high-speed motion sets a limitation on the reliability and work-rate of production lines. Neuromorphic vision is a recent technology with the potential to address the challenges of conventional vision with its high temporal resolution, low latency, and wide dynamic range. In this paper and for the first time, we propose a novel neuromorphic vision based controller for faster and more reliable machining operations, and present a complete robotic system capable of performing drilling tasks with sub-millimeter accuracy. Our proposed system localizes the target workpiece in 3D using two perception stages that we developed specifically for the asynchronous output of neuromorphic cameras. The first stage performs multi-view reconstruction for an initial estimate of the workpiece's pose, and the second stage refines this estimate for a local region of the workpiece using circular hole detection. The robot then precisely positions the drilling end-effector and drills the target holes on the workpiece using a combined position-based and image-based visual servoing approach. The proposed solution is validated experimentally for drilling nutplate holes on workpieces placed arbitrarily in an unstructured environment with uncontrolled lighting. Experimental results prove the effectiveness of our solution with an average positional errors of less than 0.1 mm, and demonstrate that the use of neuromorphic vision overcomes the lighting and speed limitations of conventional cameras.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge