Fully Convolutional Cross-Scale-Flows for Image-based Defect Detection

Paper and Code

Oct 06, 2021

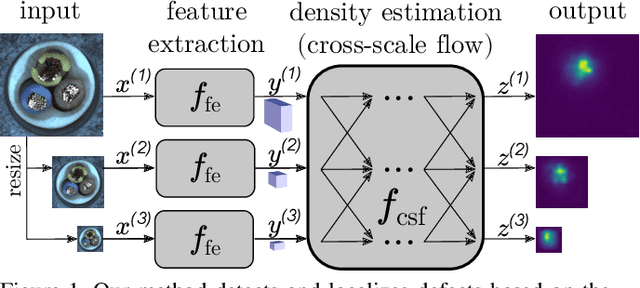

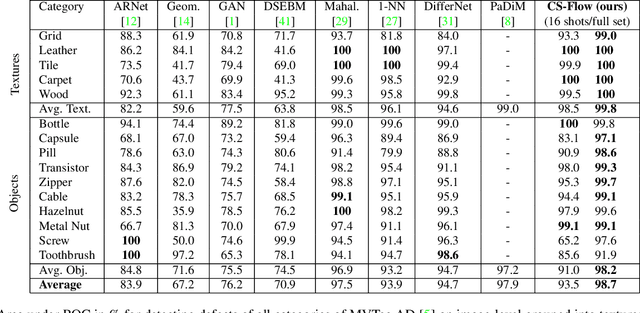

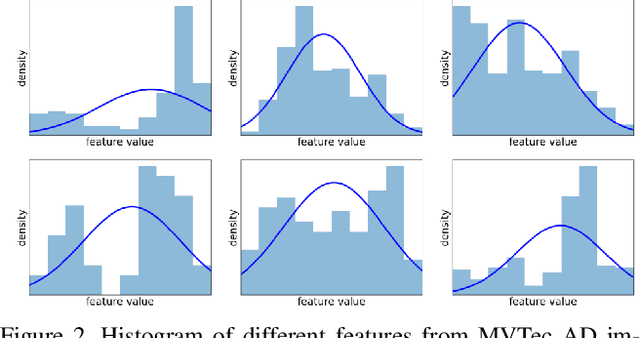

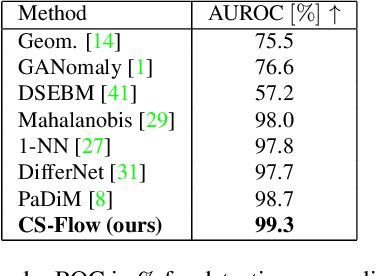

In industrial manufacturing processes, errors frequently occur at unpredictable times and in unknown manifestations. We tackle the problem of automatic defect detection without requiring any image samples of defective parts. Recent works model the distribution of defect-free image data, using either strong statistical priors or overly simplified data representations. In contrast, our approach handles fine-grained representations incorporating the global and local image context while flexibly estimating the density. To this end, we propose a novel fully convolutional cross-scale normalizing flow (CS-Flow) that jointly processes multiple feature maps of different scales. Using normalizing flows to assign meaningful likelihoods to input samples allows for efficient defect detection on image-level. Moreover, due to the preserved spatial arrangement the latent space of the normalizing flow is interpretable which enables to localize defective regions in the image. Our work sets a new state-of-the-art in image-level defect detection on the benchmark datasets Magnetic Tile Defects and MVTec AD showing a 100% AUROC on 4 out of 15 classes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge