Effect of Active and Passive Protective Soft Skins on Collision Forces in Human-robot Collaboration

Paper and Code

Mar 18, 2022

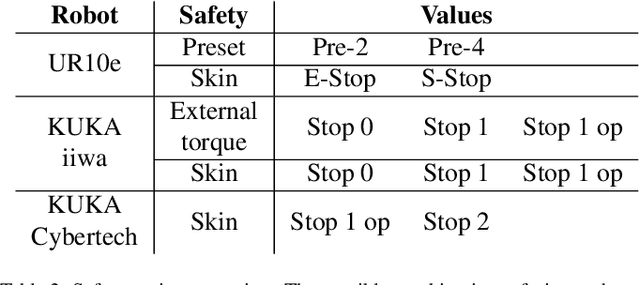

Soft electronic skins are one of the means to turn an industrial manipulator into a collaborative robot. For manipulators that are already fit for physical human-robot collaboration, soft skins can make them safer. In this work, we study the after impact behavior of two collaborative manipulators (UR10e and KUKA LBR iiwa) and one classical industrial manipulator (KUKA Cybertech), in the presence or absence of an industrial protective skin (AIRSKIN). In addition, we isolate the effects of the passive padding and the active contribution of the sensor to robot reaction. We present a total of 2250 collision measurements and study the impact force, contact duration, clamping force, and impulse. The dataset is publicly available. We summarize our results as follows. For transient collisions, the passive skin properties lowered the impact forces by about 40 %. During quasi-static contact, the effect of skin covers -- active or passive -- cannot be isolated from the collision detection and reaction by the collaborative robots. Important effects of the stop categories triggered by the active protective skin were found. We systematically compare the different settings and the empirically established safe velocities with prescriptions by the ISO/TS 15066. In some cases, up to the quadruple of the ISO/TS 15066 prescribed velocity can comply with the impact force limits and thus be considered safe. We propose an extension of the formulas relating impact force and permissible velocity that take into account the stiffness and compressible thickness of the protective cover, leading to better predictions of the collision forces. At the same time, this work emphasizes the need for in situ measurements as all the factors we studied -- presence of active/passive skin, safety stop settings, robot collision reaction, impact direction, and, of course, velocity -- have effects on the force evolution after impact.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge