Context-Based Meta Reinforcement Learning for Robust and Adaptable Peg-in-Hole Assembly Tasks

Paper and Code

Sep 24, 2024

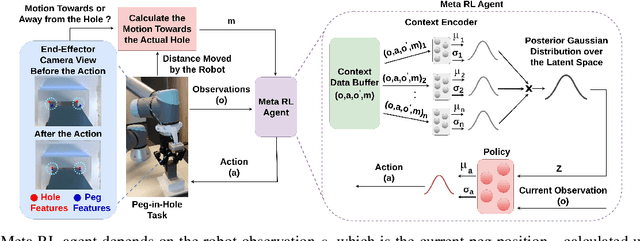

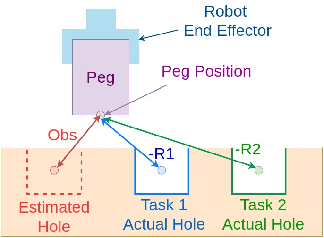

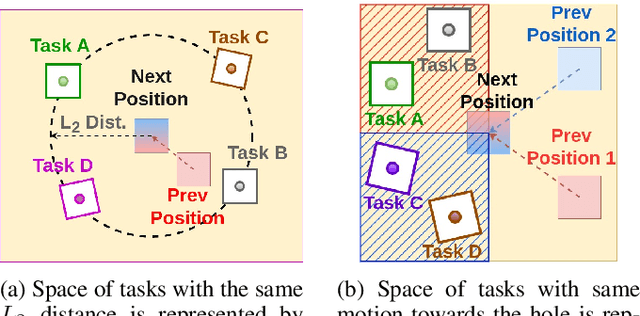

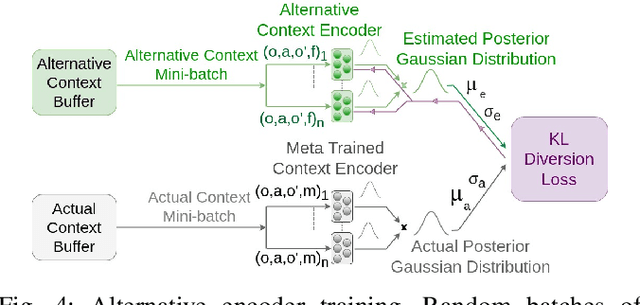

Peg-in-hole assembly in unknown environments is a challenging task due to onboard sensor errors, which result in uncertainty and variations in task parameters such as the hole position and orientation. Meta Reinforcement Learning (Meta RL) has been proposed to mitigate this problem as it learns how to quickly adapt to new tasks with different parameters. However, previous approaches either depend on a sample-inefficient procedure or human demonstrations to perform the task in the real world. Our work modifies the data used by the Meta RL agent and uses simple features that can be easily measured in the real world even with an uncalibrated camera. We further adapt the Meta RL agent to use data from a force/torque sensor, instead of the camera, to perform the assembly, using a small amount of training data. Finally, we propose a fine-tuning method that consistently and safely adapts to out-of-distribution tasks with parameters that differ by a factor of 10 from the training tasks. Our results demonstrate that the proposed data modification significantly enhances the training and adaptation efficiency and enables the agent to achieve 100% success in tasks with different hole positions and orientations. Experiments on a real robot confirm that both camera- and force/torque sensor-equipped agents achieve 100% success in tasks with unknown hole positions, matching their simulation performance and validating the approach's robustness and applicability. Compared to the previous work with sample-inefficient adaptation, our proposed methods are 10 times more sample-efficient in the real-world tasks.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge