Causal Discovery for Manufacturing Domains

Paper and Code

Jun 13, 2016

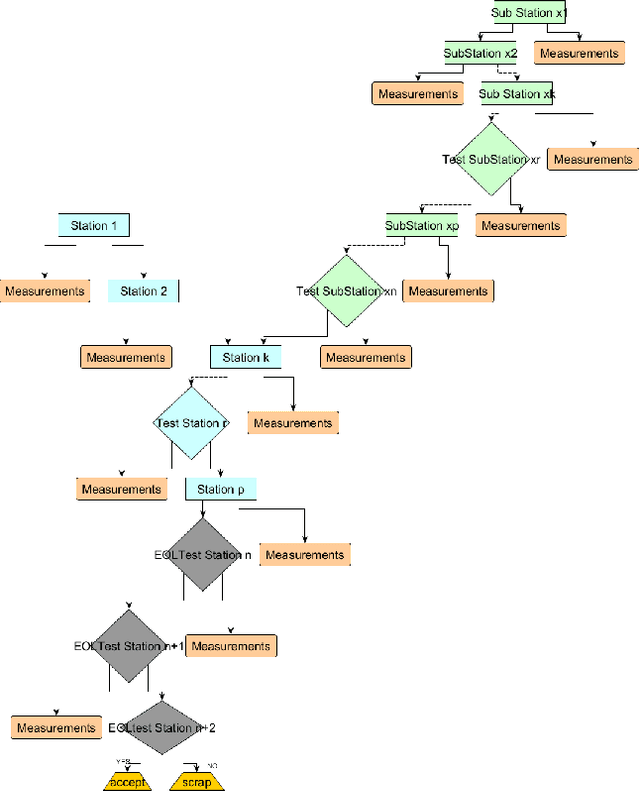

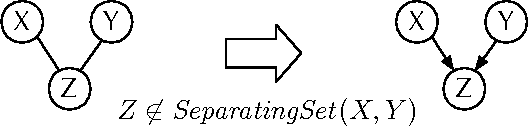

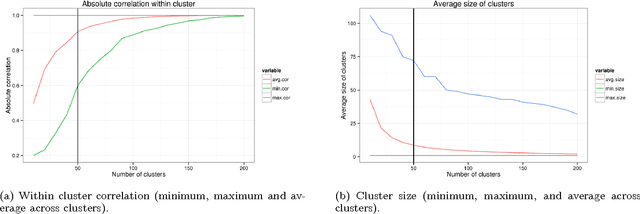

Yield and quality improvement is of paramount importance to any manufacturing company. One of the ways of improving yield is through discovery of the root causal factors affecting yield. We propose the use of data-driven interpretable causal models to identify key factors affecting yield. We focus on factors that are measured in different stages of production and testing in the manufacturing cycle of a product. We apply causal structure learning techniques on real data collected from this line. Specifically, the goal of this work is to learn interpretable causal models from observational data produced by manufacturing lines. Emphasis has been given to the interpretability of the models to make them actionable in the field of manufacturing. We highlight the challenges presented by assembly line data and propose ways to alleviate them.We also identify unique characteristics of data originating from assembly lines and how to leverage them in order to improve causal discovery. Standard evaluation techniques for causal structure learning shows that the learned causal models seem to closely represent the underlying latent causal relationship between different factors in the production process. These results were also validated by manufacturing domain experts who found them promising. This work demonstrates how data mining and knowledge discovery can be used for root cause analysis in the domain of manufacturing and connected industry.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge