Autonomous Strawberry Picking Robotic System (Robofruit)

Paper and Code

Jan 10, 2023

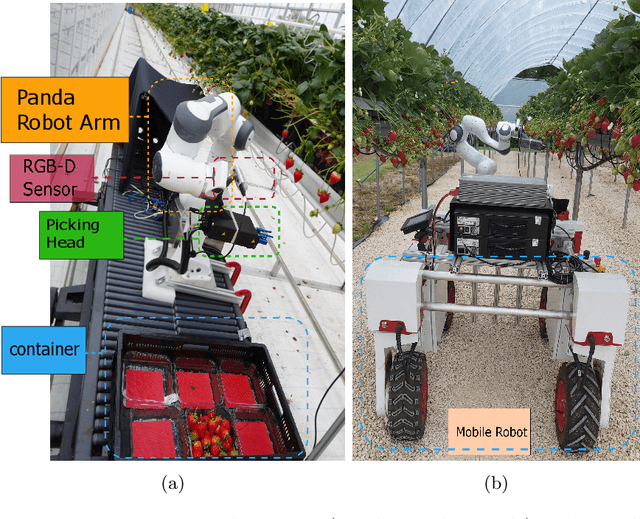

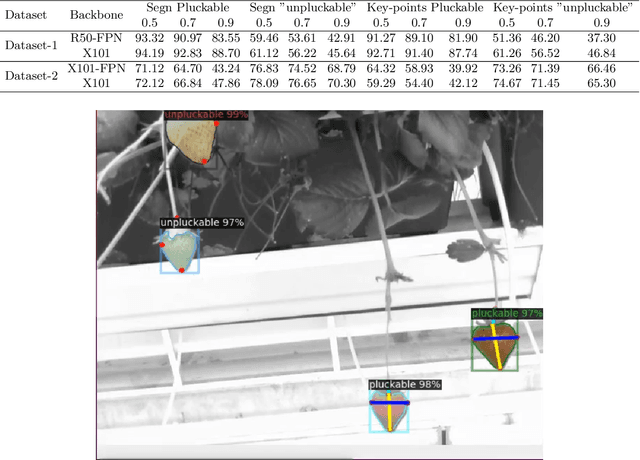

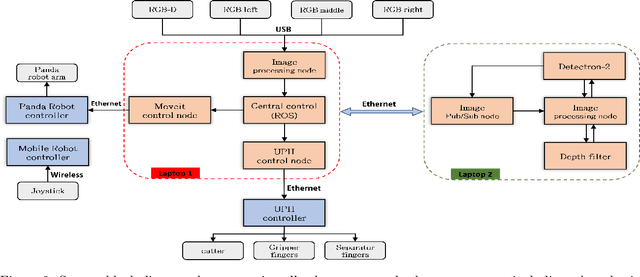

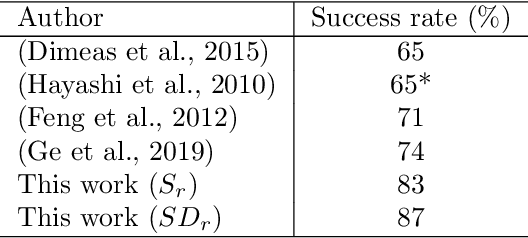

Challenges in strawberry picking made selective harvesting robotic technology demanding. However, selective harvesting of strawberries is complicated forming a few scientific research questions. Most available solutions only deal with a specific picking scenario, e.g., picking only a single variety of fruit in isolation. Nonetheless, most economically viable (e.g. high-yielding and/or disease-resistant) varieties of strawberry are grown in dense clusters. The current perception technology in such use cases is inefficient. In this work, we developed a novel system capable of harvesting strawberries with several unique features. The features allow the system to deal with very complex picking scenarios, e.g. dense clusters. Our concept of a modular system makes our system reconfigurable to adapt to different picking scenarios. We designed, manufactured, and tested a picking head with 2.5 DOF (2 independent mechanisms and 1 dependent cutting system) capable of removing possible occlusions and harvesting targeted strawberries without contacting fruit flesh to avoid damage and bruising. In addition, we developed a novel perception system to localise strawberries and detect their key points, picking points, and determine their ripeness. For this purpose, we introduced two new datasets. Finally, we tested the system in a commercial strawberry growing field and our research farm with three different strawberry varieties. The results show the effectiveness and reliability of the proposed system. The designed picking head was able to remove occlusions and harvest strawberries effectively. The perception system was able to detect and determine the ripeness of strawberries with 95% accuracy. In total, the system was able to harvest 87% of all detected strawberries with a success rate of 83% for all pluckable fruits. We also discuss a series of open research questions in the discussion section.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge