Zhixuan Lian

UBMF: Uncertainty-Aware Bayesian Meta-Learning Framework for Fault Diagnosis with Imbalanced Industrial Data

Mar 14, 2025

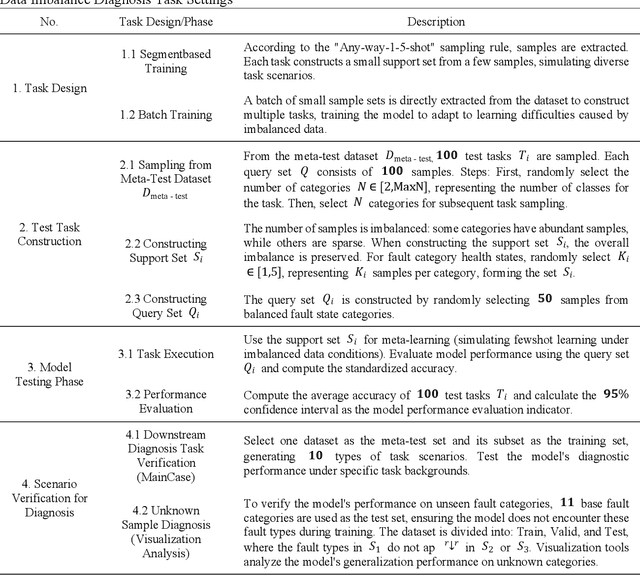

Abstract:Fault diagnosis of mechanical equipment involves data collection, feature extraction, and pattern recognition but is often hindered by the imbalanced nature of industrial data, introducing significant uncertainty and reducing diagnostic reliability. To address these challenges, this study proposes the Uncertainty-Aware Bayesian Meta-Learning Framework (UBMF), which integrates four key modules: data perturbation injection for enhancing feature robustness, cross-task self-supervised feature extraction for improving transferability, uncertainty-based sample filtering for robust out-of-domain generalization, and Bayesian meta-knowledge integration for fine-grained classification. Experimental results on ten open-source datasets under various imbalanced conditions, including cross-task, small-sample, and unseen-sample scenarios, demonstrate the superiority of UBMF, achieving an average improvement of 42.22% across ten Any-way 1-5-shot diagnostic tasks. This integrated framework effectively enhances diagnostic accuracy, generalization, and adaptability, providing a reliable solution for complex industrial fault diagnosis.

Pre-Trained Large Language Model Based Remaining Useful Life Transfer Prediction of Bearing

Jan 13, 2025

Abstract:Accurately predicting the remaining useful life (RUL) of rotating machinery, such as bearings, is essential for ensuring equipment reliability and minimizing unexpected industrial failures. Traditional data-driven deep learning methods face challenges in practical settings due to inconsistent training and testing data distributions and limited generalization for long-term predictions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge