Yonghao Yue

Model-Driven Feed-Forward Prediction for Manipulation of Deformable Objects

Jul 15, 2016

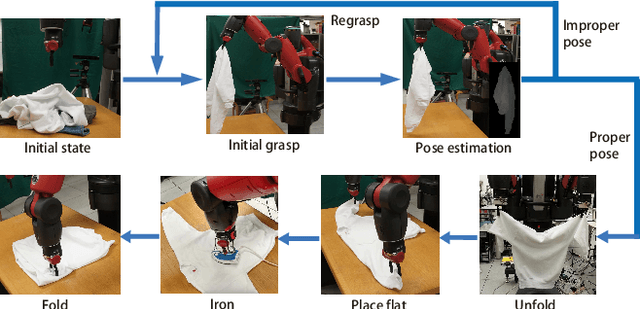

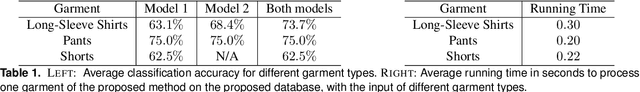

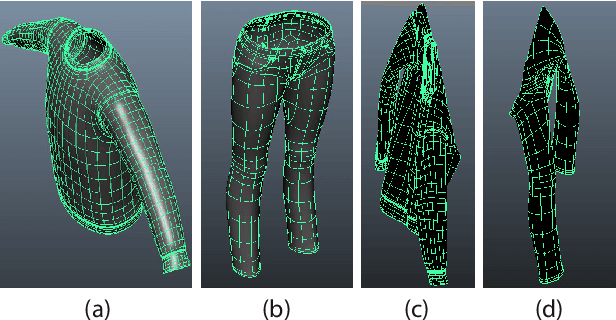

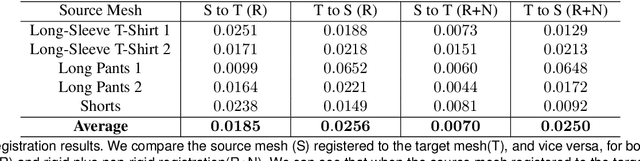

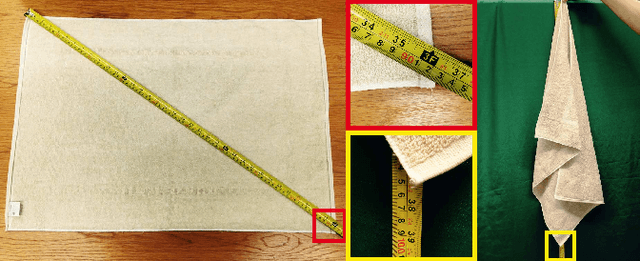

Abstract:Robotic manipulation of deformable objects is a difficult problem especially because of the complexity of the many different ways an object can deform. Searching such a high dimensional state space makes it difficult to recognize, track, and manipulate deformable objects. In this paper, we introduce a predictive, model-driven approach to address this challenge, using a pre-computed, simulated database of deformable object models. Mesh models of common deformable garments are simulated with the garments picked up in multiple different poses under gravity, and stored in a database for fast and efficient retrieval. To validate this approach, we developed a comprehensive pipeline for manipulating clothing as in a typical laundry task. First, the database is used for category and pose estimation for a garment in an arbitrary position. A fully featured 3D model of the garment is constructed in real-time and volumetric features are then used to obtain the most similar model in the database to predict the object category and pose. Second, the database can significantly benefit the manipulation of deformable objects via non-rigid registration, providing accurate correspondences between the reconstructed object model and the database models. Third, the accurate model simulation can also be used to optimize the trajectories for manipulation of deformable objects, such as the folding of garments. Extensive experimental results are shown for the tasks above using a variety of different clothing.

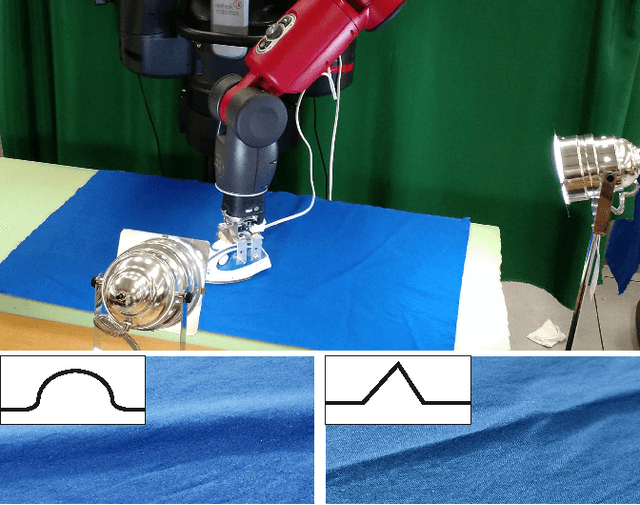

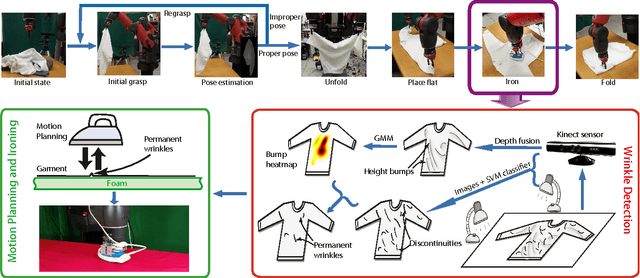

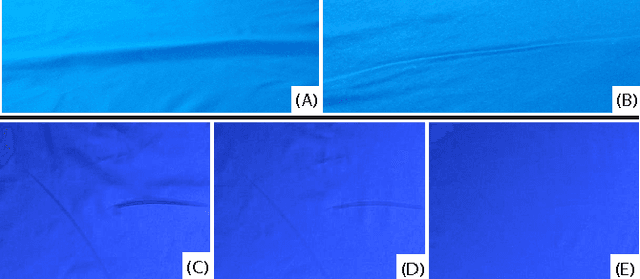

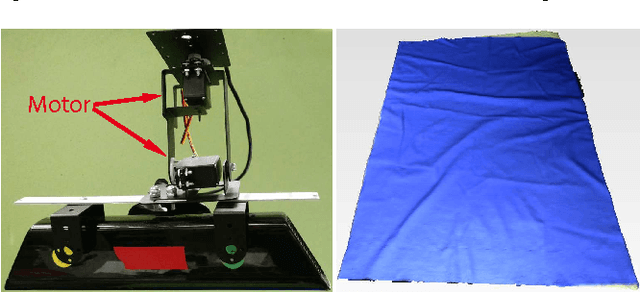

Multi-Sensor Surface Analysis for Robotic Ironing

Feb 16, 2016

Abstract:Robotic manipulation of deformable objects remains a challenging task. One such task is to iron a piece of cloth autonomously. Given a roughly flattened cloth, the goal is to have an ironing plan that can iteratively apply a regular iron to remove all the major wrinkles by a robot. We present a novel solution to analyze the cloth surface by fusing two surface scan techniques: a curvature scan and a discontinuity scan. The curvature scan can estimate the height deviation of the cloth surface, while the discontinuity scan can effectively detect sharp surface features, such as wrinkles. We use this information to detect the regions that need to be pulled and extended before ironing, and the other regions where we want to detect wrinkles and apply ironing to remove the wrinkles. We demonstrate that our hybrid scan technique is able to capture and classify wrinkles over the surface robustly. Given detected wrinkles, we enable a robot to iron them using shape features. Experimental results show that using our wrinkle analysis algorithm, our robot is able to iron the cloth surface and effectively remove the wrinkles.

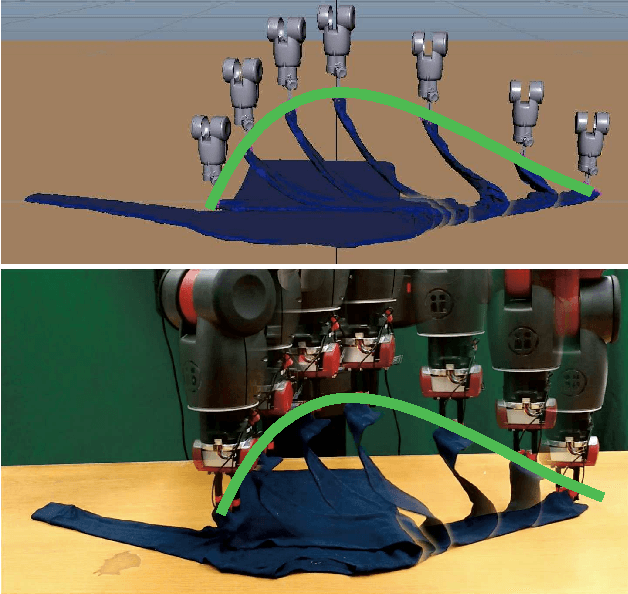

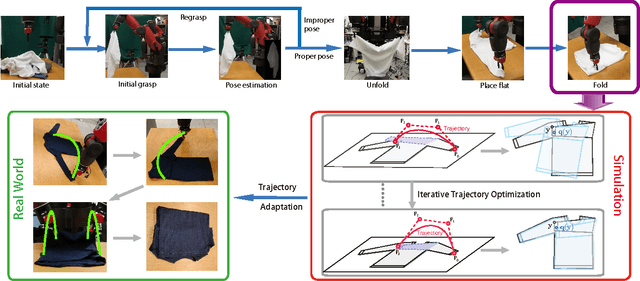

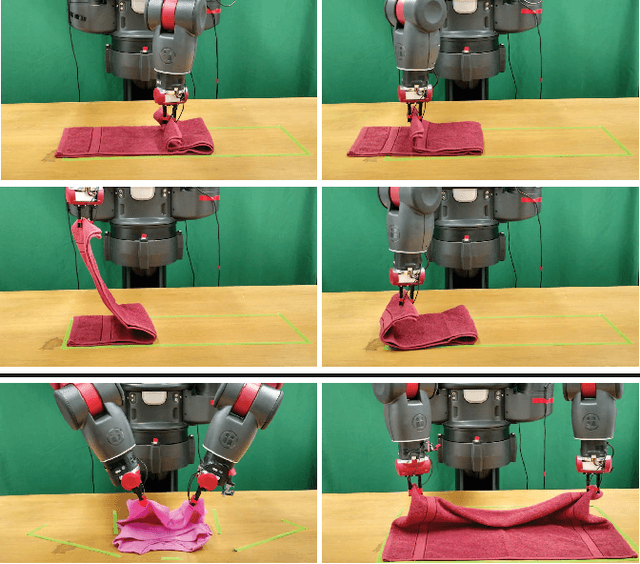

Folding Deformable Objects using Predictive Simulation and Trajectory Optimization

Dec 22, 2015

Abstract:Robotic manipulation of deformable objects remains a challenging task. One such task is folding a garment autonomously. Given start and end folding positions, what is an optimal trajectory to move the robotic arm to fold a garment? Certain trajectories will cause the garment to move, creating wrinkles, and gaps, other trajectories will fail altogether. We present a novel solution to find an optimal trajectory that avoids such problematic scenarios. The trajectory is optimized by minimizing a quadratic objective function in an off-line simulator, which includes material properties of the garment and frictional force on the table. The function measures the dissimilarity between a user folded shape and the folded garment in simulation, which is then used as an error measurement to create an optimal trajectory. We demonstrate that our two-arm robot can follow the optimized trajectories, achieving accurate and efficient manipulations of deformable objects.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge