Xiangyin Kong

Causality-driven Sequence Segmentation for Enhancing Multiphase Industrial Process Data Analysis and Soft Sensing

Jun 30, 2024Abstract:The dynamic characteristics of multiphase industrial processes present significant challenges in the field of industrial big data modeling. Traditional soft sensing models frequently neglect the process dynamics and have difficulty in capturing transient phenomena like phase transitions. To address this issue, this article introduces a causality-driven sequence segmentation (CDSS) model. This model first identifies the local dynamic properties of the causal relationships between variables, which are also referred to as causal mechanisms. It then segments the sequence into different phases based on the sudden shifts in causal mechanisms that occur during phase transitions. Additionally, a novel metric, similarity distance, is designed to evaluate the temporal consistency of causal mechanisms, which includes both causal similarity distance and stable similarity distance. The discovered causal relationships in each phase are represented as a temporal causal graph (TCG). Furthermore, a soft sensing model called temporal-causal graph convolutional network (TC-GCN) is trained for each phase, by using the time-extended data and the adjacency matrix of TCG. The numerical examples are utilized to validate the proposed CDSS model, and the segmentation results demonstrate that CDSS has excellent performance on segmenting both stable and unstable multiphase series. Especially, it has higher accuracy in separating non-stationary time series compared to other methods. The effectiveness of the proposed CDSS model and the TC-GCN model is also verified through a penicillin fermentation process. Experimental results indicate that the breakpoints discovered by CDSS align well with the reaction mechanisms and TC-GCN significantly has excellent predictive accuracy.

Latent Variable Models in the Era of Industrial Big Data: Extension and Beyond

Aug 23, 2022

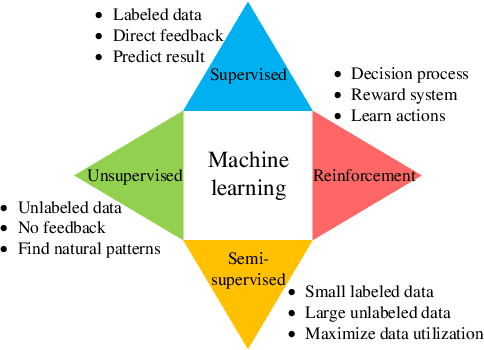

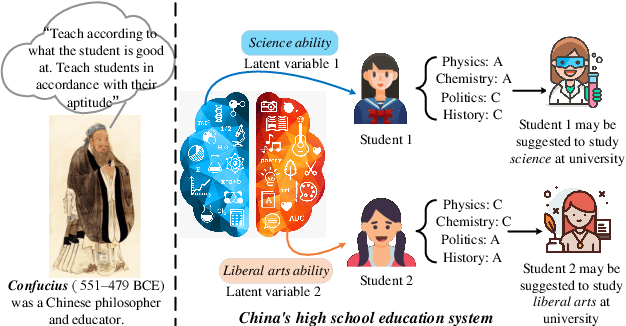

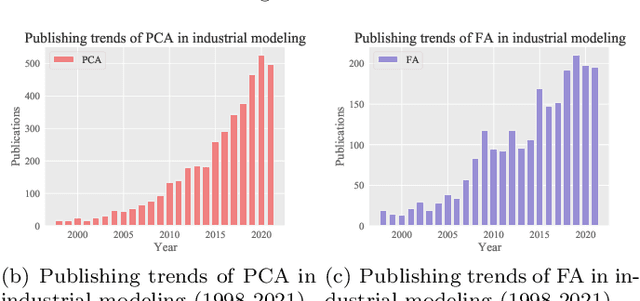

Abstract:A rich supply of data and innovative algorithms have made data-driven modeling a popular technique in modern industry. Among various data-driven methods, latent variable models (LVMs) and their counterparts account for a major share and play a vital role in many industrial modeling areas. LVM can be generally divided into statistical learning-based classic LVM and neural networks-based deep LVM (DLVM). We first discuss the definitions, theories and applications of classic LVMs in detail, which serves as both a comprehensive tutorial and a brief application survey on classic LVMs. Then we present a thorough introduction to current mainstream DLVMs with emphasis on their theories and model architectures, soon afterwards provide a detailed survey on industrial applications of DLVMs. The aforementioned two types of LVM have obvious advantages and disadvantages. Specifically, classic LVMs have concise principles and good interpretability, but their model capacity cannot address complicated tasks. Neural networks-based DLVMs have sufficient model capacity to achieve satisfactory performance in complex scenarios, but it comes at sacrifices in model interpretability and efficiency. Aiming at combining the virtues and mitigating the drawbacks of these two types of LVMs, as well as exploring non-neural-network manners to build deep models, we propose a novel concept called lightweight deep LVM (LDLVM). After proposing this new idea, the article first elaborates the motivation and connotation of LDLVM, then provides two novel LDLVMs, along with thorough descriptions on their principles, architectures and merits. Finally, outlooks and opportunities are discussed, including important open questions and possible research directions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge