X. -G. Ma

International Institute for Urban Systems Engineering, Southeast University, Nanjing, China

Group-Mix SAM: Lightweight Solution for Industrial Assembly Line Applications

Mar 15, 2024Abstract:Since the advent of the Segment Anything Model(SAM) approximately one year ago, it has engendered significant academic interest and has spawned a large number of investigations and publications from various perspectives. However, the deployment of SAM in practical assembly line scenarios has yet to materialize due to its large image encoder, which weighs in at an imposing 632M. In this study, we have replaced the heavyweight image encoder with a lightweight one, thereby enabling the deployment of SAM in practical assembly line scenarios. Specifically, we have employed decoupled distillation to train the encoder of MobileSAM in a resource-limited setting. The entire knowledge distillation experiment can be completed in a single day on a single RTX 4090. The resulting lightweight SAM, referred to as Group-Mix SAM, had 37.63% (2.16M) fewer parameters and 42.5% (15614.7M) fewer floating-point operations compared to MobileSAM. However, on our constructed industrial dataset, MALSD, its mIoU was only marginally lower than that of MobileSAM, at 0.615. Finally, we conducted a comprehensive comparative experiment to demonstrate the superiority of Group-Mix SAM in the industrial domain. With its exceptional performance, our Group-Mix SAM is more suitable for practical assembly line applications.

Leveraging Foundation Model Automatic Data Augmentation Strategies and Skeletal Points for Hands Action Recognition in Industrial Assembly Lines

Mar 14, 2024

Abstract:On modern industrial assembly lines, many intelligent algorithms have been developed to replace or supervise workers. However, we found that there were bottlenecks in both training datasets and real-time performance when deploying algorithms on actual assembly line. Therefore, we developed a promising strategy for expanding industrial datasets, which utilized large models with strong generalization abilities to achieve efficient, high-quality, and large-scale dataset expansion, solving the problem of insufficient and low-quality industrial datasets. We also applied this strategy to video action recognition. We proposed a method of converting hand action recognition problems into hand skeletal trajectory classification problems, which solved the real-time performance problem of industrial algorithms. In the "hand movements during wire insertion" scenarios on the actual assembly line, the accuracy of hand action recognition reached 98.8\%. We conducted detailed experimental analysis to demonstrate the effectiveness and superiority of the method, and deployed the entire process on Midea's actual assembly line.

Drone LAMS: A Drone-based Face Detection Dataset with Large Angles and Many Scenarios

Nov 16, 2020

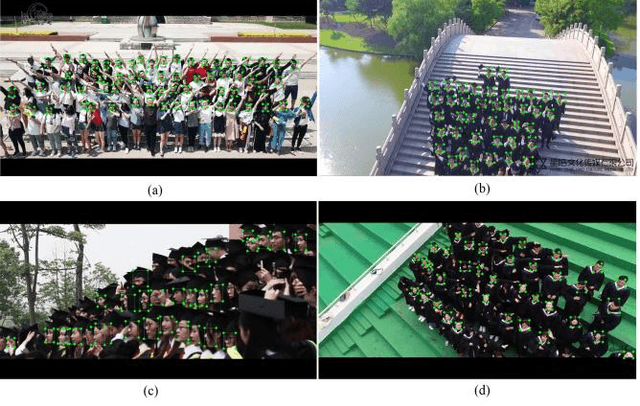

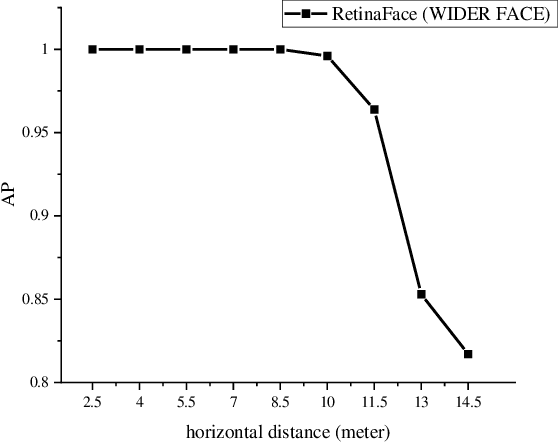

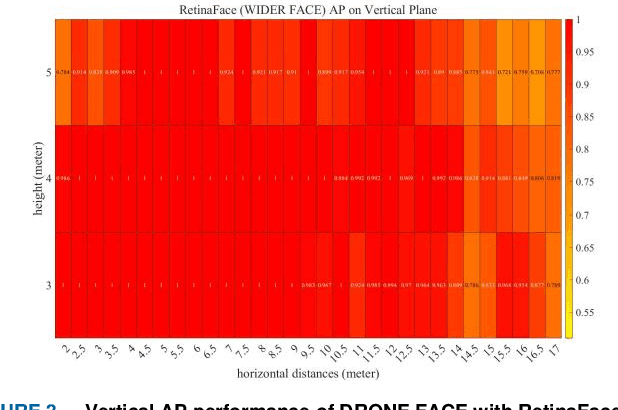

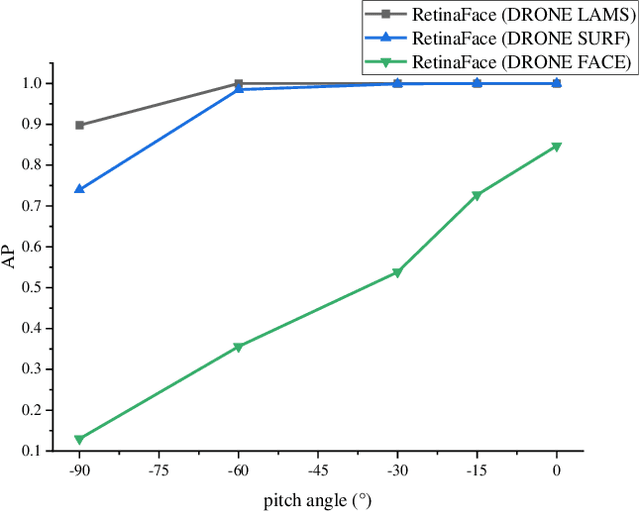

Abstract:This work presented a new drone-based face detection dataset Drone LAMS in order to solve issues of low performance of drone-based face detection in scenarios such as large angles which was a predominant working condition when a drone flies high. The proposed dataset captured images from 261 videos with over 43k annotations and 4.0k images with pitch or yaw angle in the range of -90{\deg} to 90{\deg}. Drone LAMS showed significant improvement over currently available drone-based face detection datasets in terms of detection performance, especially with large pitch and yaw angle. Detailed analysis of how key factors, such as duplication rate, annotation method, etc., impact dataset performance was also provided to facilitate further usage of a drone on face detection.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge