Weiming Ba

Design, Modelling and Validation of a Novel Extra Slender Continuum Robot for In-situ Inspection and Repair in Aeroengine

Oct 09, 2019

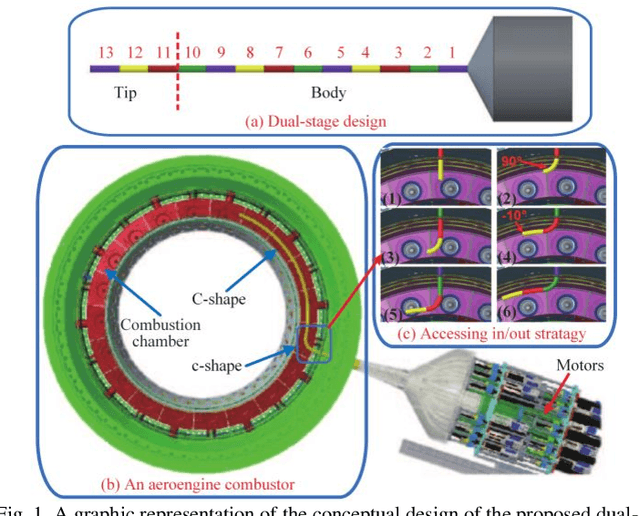

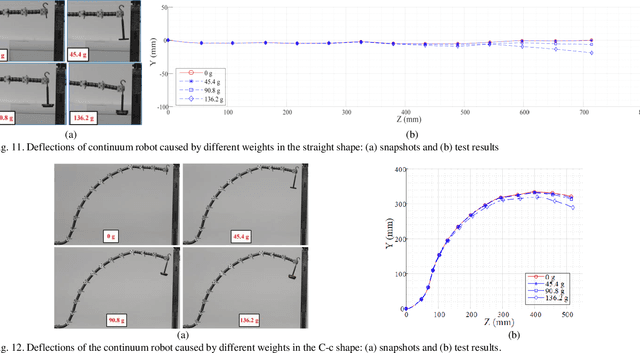

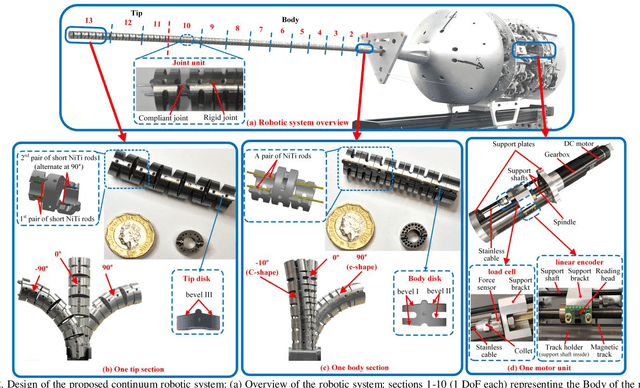

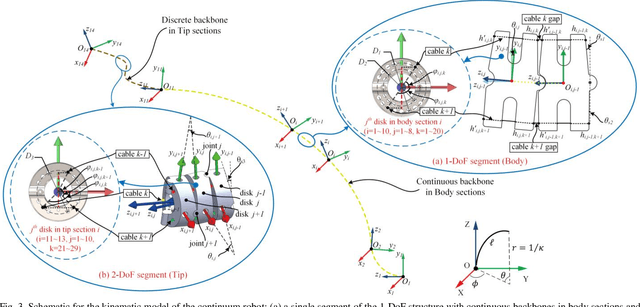

Abstract:In-situ aeroengine maintenance works are highly beneficial as it can significantly reduce the current maintenance cycle which is extensive and costly due to the disassembly requirement of engines from aircrafts. However, navigating in/out via inspection ports and performing multi-axis movements with end-effectors in constrained environments (e.g. combustion chamber) are fairly challenging. A novel extra-slender (diameter-to-length ratio <0.02) dual-stage continuum robot (16 degree-of-freedom) is proposed to navigate in/out confined environments and perform required configuration shapes for further repair operations. Firstly, the robot design presents several innovative mechatronic solutions: (i) dual-stage tendon-driven structure with bevelled disks to perform required shapes and to provide selective stiffness for carrying high payloads; (ii) various rigid-compliant combined joints to enable different flexibility and stiffness in each stage; (iii) three commanding cables for each 2-DoF section to minimise the number of actuators with precise actuations. Secondly, a segment-scaled piecewise-constant-curvature-theory based kinematic model and a Kirchhoff-elastic-rod-theory based static model are established by considering the applied forces/moments (friction, actuation, gravity and external load), where the friction coefficient is modelled as a function of bending angle. Finally, experiments were carried out to validate the proposed static modelling and to evaluate the robot capabilities of performing the predefined shape and stiffness.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge