Timo Müller

Intelligent Exploration of Solution Spaces Exemplified by Industrial Reconfiguration Management

Jul 04, 2022

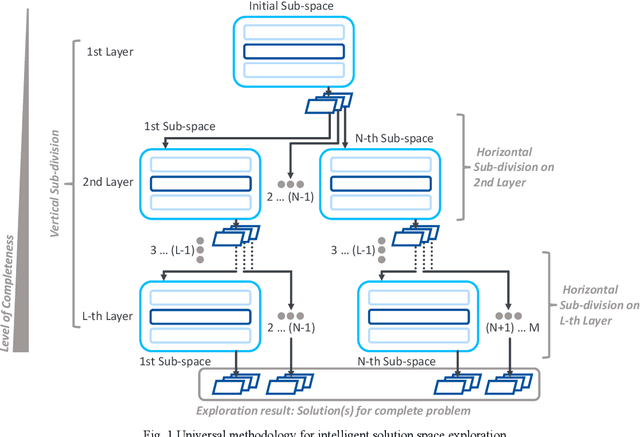

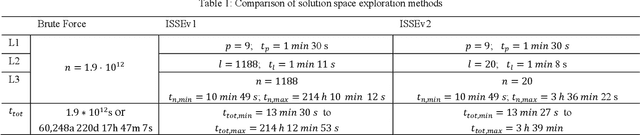

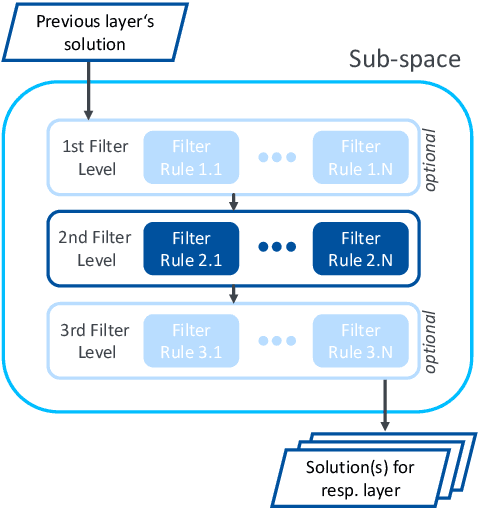

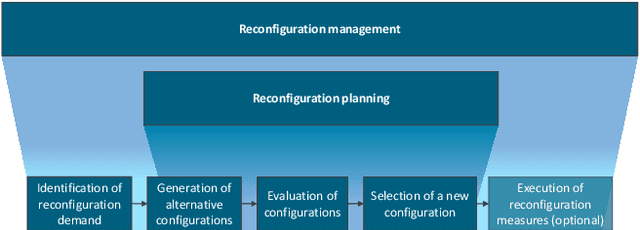

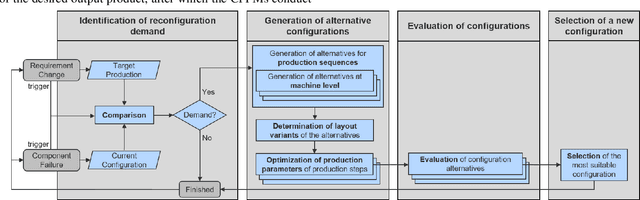

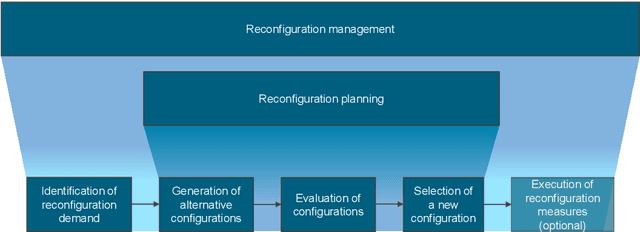

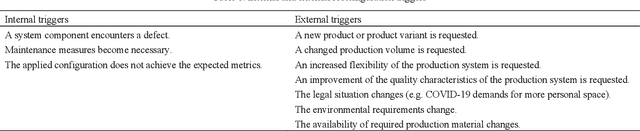

Abstract:Many decision-making approaches rely on the exploration of solution spaces with regards to specified criteria. However, in complex environments, brute-force exploration strategies are usually not feasible. As an alternative, we propose the combination of an exploration task's vertical sub-division into layers representing different sequentially interdependent sub-problems of the paramount problem and a horizontal sub-division into self-sustained solution sub-spaces. In this paper, we present a universal methodology for the intelligent exploration of solution spaces and derive a use-case specific example from the field of reconfiguration management in industry 4.0.

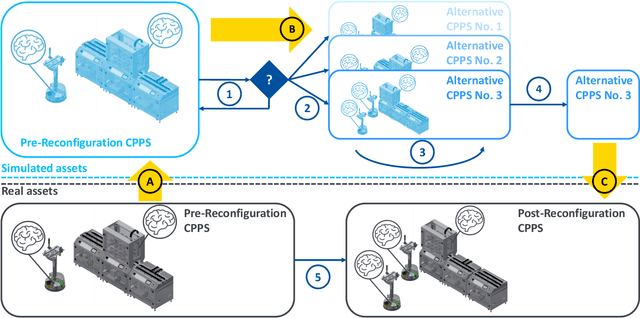

Enhancing an Intelligent Digital Twin with a Self-organized Reconfiguration Management based on Adaptive Process Models

Jul 07, 2021

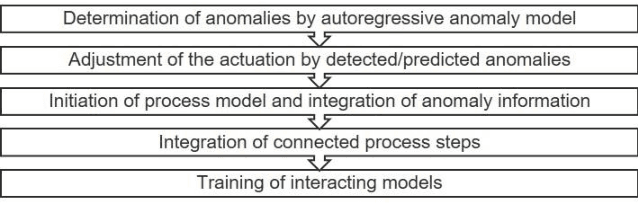

Abstract:Shorter product life cycles and increasing individualization of production leads to an increased reconfiguration demand in the domain of industrial automation systems, which will be dominated by cyber-physical production systems in the future. In constantly changing systems, however, not all configuration alternatives of the almost infinite state space are fully understood. Thus, certain configurations can lead to process instability, a reduction in quality or machine failures. Therefore, this paper presents an approach that enhances an intelligent Digital Twin with a self-organized reconfiguration management based on adaptive process models in order to find optimized configurations more comprehensively.

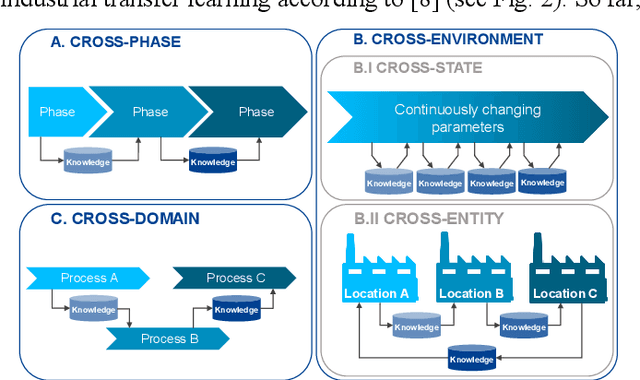

Transfer Learning as an Enhancement for Reconfiguration Management of Cyber-Physical Production Systems

May 31, 2021

Abstract:Reconfiguration demand is increasing due to frequent requirement changes for manufacturing systems. Recent approaches aim at investigating feasible configuration alternatives from which they select the optimal one. This relies on processes whose behavior is not reliant on e.g. the production sequence. However, when machine learning is used, components' behavior depends on the process' specifics, requiring additional concepts to successfully conduct reconfiguration management. Therefore, we propose the enhancement of the comprehensive reconfiguration management with transfer learning. This provides the ability to assess the machine learning dependent behavior of the different CPPS configurations with reduced effort and further assists the recommissioning of the chosen one. A real cyber-physical production system from the discrete manufacturing domain is utilized to demonstrate the aforementioned proposal.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge