Teruki Kato

Convex Chance-Constrained Stochastic Control under Uncertain Specifications with Application to Learning-Based Hybrid Powertrain Control

Jan 26, 2026Abstract:This paper presents a strictly convex chance-constrained stochastic control framework that accounts for uncertainty in control specifications such as reference trajectories and operational constraints. By jointly optimizing control inputs and risk allocation under general (possibly non-Gaussian) uncertainties, the proposed method guarantees probabilistic constraint satisfaction while ensuring strict convexity, leading to uniqueness and continuity of the optimal solution. The formulation is further extended to nonlinear model-based control using exactly linearizable models identified through machine learning. The effectiveness of the proposed approach is demonstrated through model predictive control applied to a hybrid powertrain system.

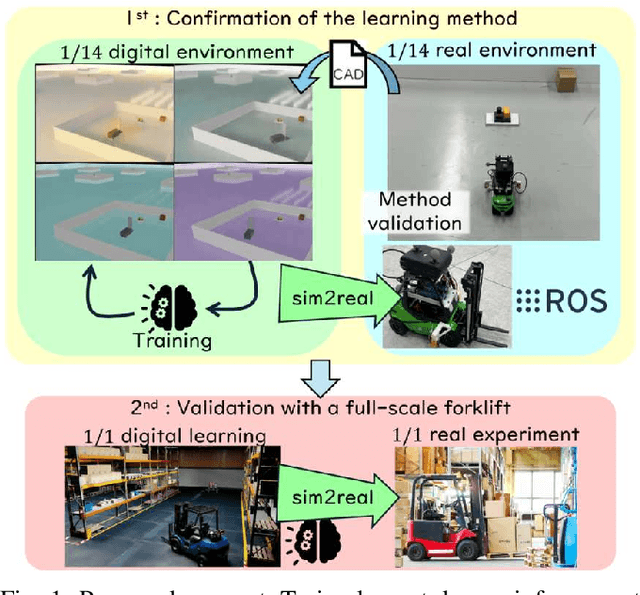

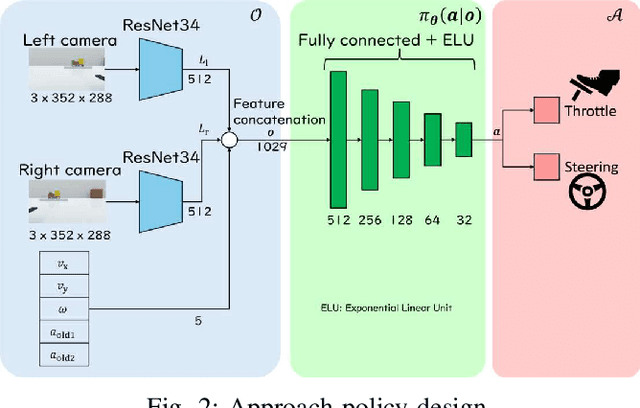

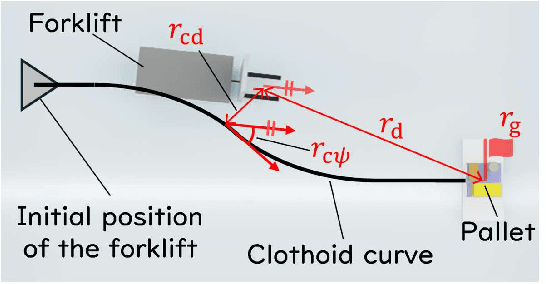

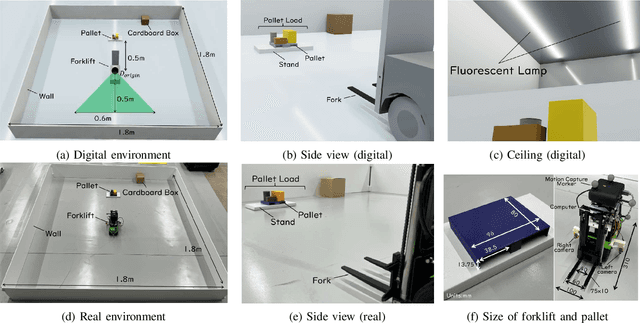

Visual-Based Forklift Learning System Enabling Zero-Shot Sim2Real Without Real-World Data

Dec 16, 2024

Abstract:Forklifts are used extensively in various industrial settings and are in high demand for automation. In particular, counterbalance forklifts are highly versatile and employed in diverse scenarios. However, efforts to automate these processes are lacking, primarily owing to the absence of a safe and performance-verifiable development environment. This study proposes a learning system that combines a photorealistic digital learning environment with a 1/14-scale robotic forklift environment to address this challenge. Inspired by the training-based learning approach adopted by forklift operators, we employ an end-to-end vision-based deep reinforcement learning approach. The learning is conducted in a digitalized environment created from CAD data, making it safe and eliminating the need for real-world data. In addition, we safely validate the method in a physical setting utilizing a 1/14-scale robotic forklift with a configuration similar to that of a real forklift. We achieved a 60% success rate in pallet loading tasks in real experiments using a robotic forklift. Our approach demonstrates zero-shot sim2real with a simple method that does not require heuristic additions. This learning-based approach is considered a first step towards the automation of counterbalance forklifts.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge