Svyatoslav Korneev

Accelerating Part-Scale Simulation in Liquid Metal Jet Additive Manufacturing via Operator Learning

Feb 02, 2022

Abstract:Predicting part quality for additive manufacturing (AM) processes requires high-fidelity numerical simulation of partial differential equations (PDEs) governing process multiphysics on a scale of minimum manufacturable features. This makes part-scale predictions computationally demanding, especially when they require many small-scale simulations. We consider drop-on-demand liquid metal jetting (LMJ) as an illustrative example of such computational complexity. A model describing droplet coalescence for LMJ may include coupled incompressible fluid flow, heat transfer, and phase change equations. Numerically solving these equations becomes prohibitively expensive when simulating the build process for a full part consisting of thousands to millions of droplets. Reduced-order models (ROMs) based on neural networks (NN) or k-nearest neighbor (kNN) algorithms have been built to replace the original physics-based solver and are computationally tractable for part-level simulations. However, their quick inference capabilities often come at the expense of accuracy, robustness, and generalizability. We apply an operator learning (OL) approach to learn a mapping between initial and final states of the droplet coalescence process for enabling rapid and accurate part-scale build simulation. Preliminary results suggest that OL requires order-of-magnitude fewer data points than a kNN approach and is generalizable beyond the training set while achieving similar prediction error.

* Paper #25

Constrained Image Generation Using Binarized Neural Networks with Decision Procedures

Feb 24, 2018

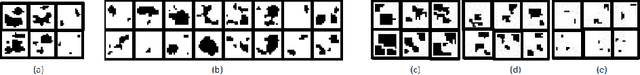

Abstract:We consider the problem of binary image generation with given properties. This problem arises in a number of practical applications, including generation of artificial porous medium for an electrode of lithium-ion batteries, for composed materials, etc. A generated image represents a porous medium and, as such, it is subject to two sets of constraints: topological constraints on the structure and process constraints on the physical process over this structure. To perform image generation we need to define a mapping from a porous medium to its physical process parameters. For a given geometry of a porous medium, this mapping can be done by solving a partial differential equation (PDE). However, embedding a PDE solver into the search procedure is computationally expensive. We use a binarized neural network to approximate a PDE solver. This allows us to encode the entire problem as a logical formula. Our main contribution is that, for the first time, we show that this problem can be tackled using decision procedures. Our experiments show that our model is able to produce random constrained images that satisfy both topological and process constraints.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge