Stavros Vougioukas

Fast Heuristic Scheduling and Trajectory Planning for Robotic Fruit Harvesters with Multiple Cartesian Arms

May 15, 2025

Abstract:This work proposes a fast heuristic algorithm for the coupled scheduling and trajectory planning of multiple Cartesian robotic arms harvesting fruits. Our method partitions the workspace, assigns fruit-picking sequences to arms, determines tight and feasible fruit-picking schedules and vehicle travel speed, and generates smooth, collision-free arm trajectories. The fruit-picking throughput achieved by the algorithm was assessed using synthetically generated fruit coordinates and a harvester design featuring up to 12 arms. The throughput increased monotonically as more arms were added. Adding more arms when fruit densities were low resulted in diminishing gains because it took longer to travel from one fruit to another. However, when there were enough fruits, the proposed algorithm achieved a linear speedup as the number of arms increased.

Efficient and Safe Trajectory Planning for Autonomous Agricultural Vehicle Headland Turning in Cluttered Orchard Environments

Jan 18, 2025

Abstract:Autonomous agricultural vehicles (AAVs), including field robots and autonomous tractors, are becoming essential in modern farming by improving efficiency and reducing labor costs. A critical task in AAV operations is headland turning between crop rows. This task is challenging in orchards with limited headland space, irregular boundaries, operational constraints, and static obstacles. While traditional trajectory planning methods work well in arable farming, they often fail in cluttered orchard environments. This letter presents a novel trajectory planner that enhances the safety and efficiency of AAV headland maneuvers, leveraging advancements in autonomous driving. Our approach includes an efficient front-end algorithm and a high-performance back-end optimization. Applied to vehicles with various implements, it outperforms state-of-the-art methods in both standard and challenging orchard fields. This work bridges agricultural and autonomous driving technologies, facilitating a broader adoption of AAVs in complex orchards.

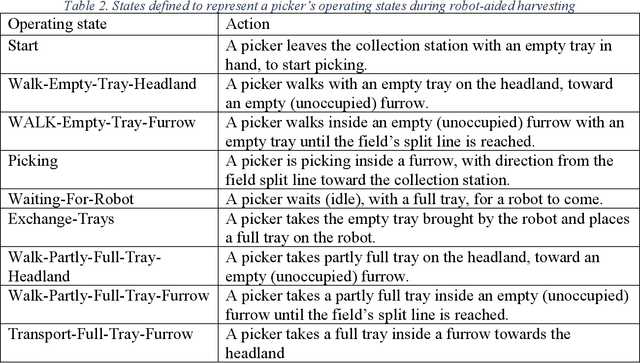

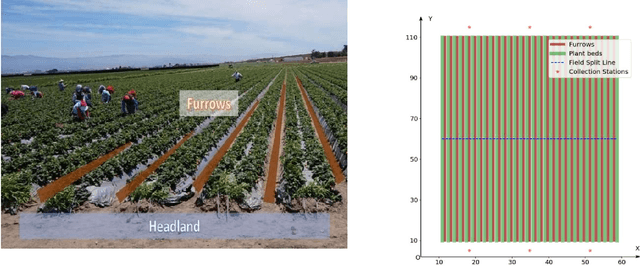

A strawberry harvest-aiding system with crop-transport co-robots: Design, development, and field evaluation

Jul 27, 2021

Abstract:Mechanizing the manual harvesting of fresh market fruits constitutes one of the biggest challenges to the sustainability of the fruit industry. During manual harvesting of some fresh-market crops like strawberries and table grapes, pickers spend significant amounts of time walking to carry full trays to a collection station at the edge of the field. A step toward increasing harvest automation for such crops is to deploy harvest-aid collaborative robots (co-bots) that transport the empty and full trays, thus increasing harvest efficiency by reducing pickers' non-productive walking times. This work presents the development of a co-robotic harvest-aid system and its evaluation during commercial strawberry harvesting. At the heart of the system lies a predictive stochastic scheduling algorithm that minimizes the expected non-picking time, thus maximizing the harvest efficiency. During the evaluation experiments, the co-robots improved the mean harvesting efficiency by around 10% and reduced the mean non-productive time by 60%, when the robot-to-picker ratio was 1:3. The concepts developed in this work can be applied to robotic harvest-aids for other manually harvested crops that involve walking for crop transportation.

Row-sensing Templates: A Generic 3D Sensor-based Approach to Robot Localization with Respect to Orchard Row Centerlines

Jul 03, 2021

Abstract:Accurate robot localization relative to orchard row centerlines is essential for autonomous guidance where satellite signals are often obstructed by foliage. Existing sensor-based approaches rely on various features extracted from images and point clouds. However, any selected features are not available consistently, because the visual and geometrical characteristics of orchard rows change drastically when tree types, growth stages, canopy management practices, seasons, and weather conditions change. In this work, we introduce a novel localization method that doesn't rely on features; instead, it relies on the concept of a row-sensing template, which is the expected observation of a 3D sensor traveling in an orchard row, when the sensor is anywhere on the centerline and perfectly aligned with it. First, the template is built using a few measurements, provided that the sensor's true pose with respect to the centerline is available. Then, during navigation, the best pose estimate (and its confidence) is estimated by maximizing the match between the template and the sensed point cloud using particle-filtering. The method can adapt to various orchards and conditions by re-building the template. Experiments were performed in a vineyard, and in an orchard in different seasons. Results showed that the lateral mean absolute error (MAE) was less than 3.6% of the row width, and the heading MAE was less than 1.72 degrees. Localization was robust, as errors didn't increase when less than 75% of measurement points were missing. The results indicate that template-based localization can provide a generic approach for accurate and robust localization in real-world orchards.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge