Sadok Sassi

Exploring Sound vs Vibration for Robust Fault Detection on Rotating Machinery

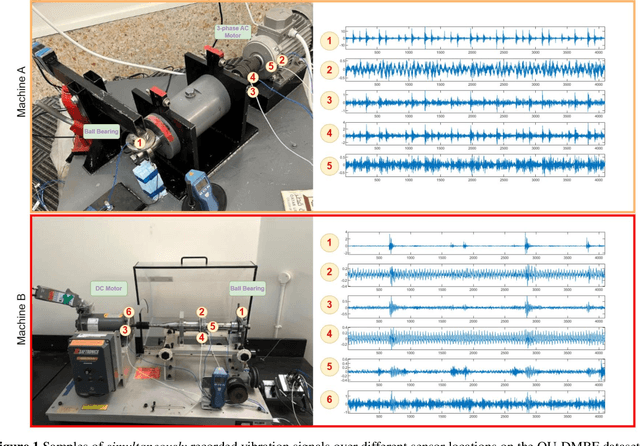

Dec 17, 2023Abstract:Robust and real-time detection of faults on rotating machinery has become an ultimate objective for predictive maintenance in various industries. Vibration-based Deep Learning (DL) methodologies have become the de facto standard for bearing fault detection as they can produce state-of-the-art detection performances under certain conditions. Despite such particular focus on the vibration signal, the utilization of sound, on the other hand, has been neglected whilst only a few studies have been proposed during the last two decades, all of which were based on a conventional ML approach. One major reason is the lack of a benchmark dataset providing a large volume of both vibration and sound data over several working conditions for different machines and sensor locations. In this study, we address this need by presenting the new benchmark Qatar University Dual-Machine Bearing Fault Benchmark dataset (QU-DMBF), which encapsulates sound and vibration data from two different motors operating under 1080 working conditions overall. Then we draw the focus on the major limitations and drawbacks of vibration-based fault detection due to numerous installation and operational conditions. Finally, we propose the first DL approach for sound-based fault detection and perform comparative evaluations between the sound and vibration over the QU-DMBF dataset. A wide range of experimental results shows that the sound-based fault detection method is significantly more robust than its vibration-based counterpart, as it is entirely independent of the sensor location, cost-effective (requiring no sensor and sensor maintenance), and can achieve the same level of the best detection performance by its vibration-based counterpart. With this study, the QU-DMBF dataset, the optimized source codes in PyTorch, and comparative evaluations are now publicly shared.

Sound-to-Vibration Transformation for Sensorless Motor Health Monitoring

May 13, 2023

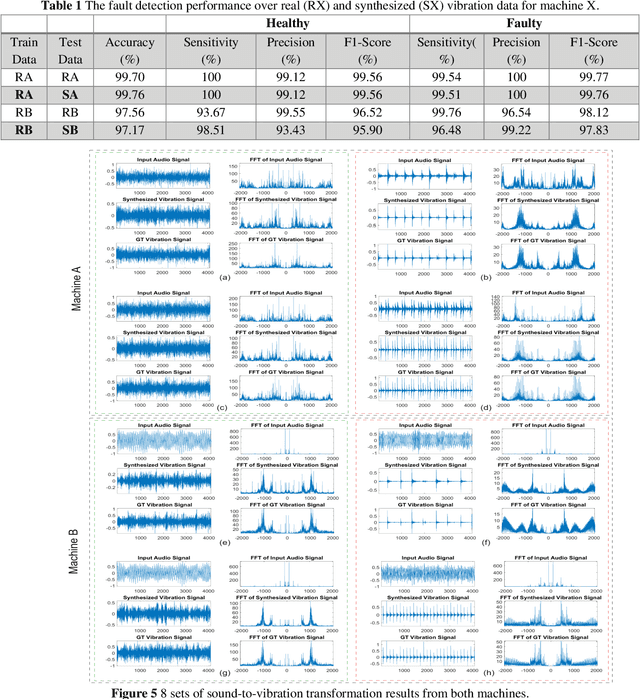

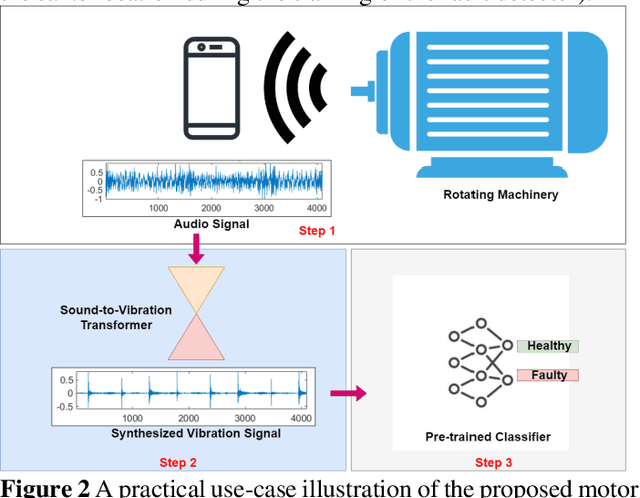

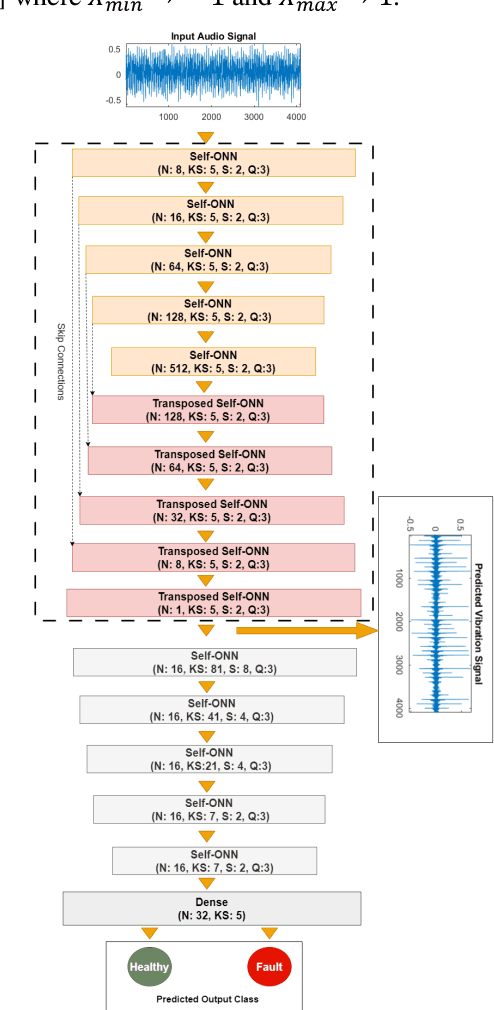

Abstract:Automatic sensor-based detection of motor failures such as bearing faults is crucial for predictive maintenance in various industries. Numerous methodologies have been developed over the years to detect bearing faults. Despite the appearance of numerous different approaches for diagnosing faults in motors have been proposed, vibration-based methods have become the de facto standard and the most commonly used techniques. However, acquiring reliable vibration signals, especially from rotating machinery, can sometimes be infeasibly difficult due to challenging installation and operational conditions (e.g., variations on accelerometer locations on the motor body), which will not only alter the signal patterns significantly but may also induce severe artifacts. Moreover, sensors are costly and require periodic maintenance to sustain a reliable signal acquisition. To address these drawbacks and void the need for vibration sensors, in this study, we propose a novel sound-to-vibration transformation method that can synthesize realistic vibration signals directly from the sound measurements regardless of the working conditions, fault type, and fault severity. As a result, using this transformation, the data acquired by a simple sound recorder, e.g., a mobile phone, can be transformed into the vibration signal, which can then be used for fault detection by a pre-trained model. The proposed method is extensively evaluated over the benchmark Qatar University Dual-Machine Bearing Fault Benchmark dataset (QU-DMBF), which encapsulates sound and vibration data from two different machines operating under various conditions. Experimental results show that this novel approach can synthesize such realistic vibration signals that can directly be used for reliable and highly accurate motor health monitoring.

Zero-Shot Motor Health Monitoring by Blind Domain Transition

Dec 12, 2022Abstract:Continuous long-term monitoring of motor health is crucial for the early detection of abnormalities such as bearing faults (up to 51% of motor failures are attributed to bearing faults). Despite numerous methodologies proposed for bearing fault detection, most of them require normal (healthy) and abnormal (faulty) data for training. Even with the recent deep learning (DL) methodologies trained on the labeled data from the same machine, the classification accuracy significantly deteriorates when one or few conditions are altered. Furthermore, their performance suffers significantly or may entirely fail when they are tested on another machine with entirely different healthy and faulty signal patterns. To address this need, in this pilot study, we propose a zero-shot bearing fault detection method that can detect any fault on a new (target) machine regardless of the working conditions, sensor parameters, or fault characteristics. To accomplish this objective, a 1D Operational Generative Adversarial Network (Op-GAN) first characterizes the transition between normal and fault vibration signals of (a) source machine(s) under various conditions, sensor parameters, and fault types. Then for a target machine, the potential faulty signals can be generated, and over its actual healthy and synthesized faulty signals, a compact, and lightweight 1D Self-ONN fault detector can then be trained to detect the real faulty condition in real time whenever it occurs. To validate the proposed approach, a new benchmark dataset is created using two different motors working under different conditions and sensor locations. Experimental results demonstrate that this novel approach can accurately detect any bearing fault achieving an average recall rate of around 89% and 95% on two target machines regardless of its type, severity, and location.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge