Robert Skilton

Neural Value Iteration

Nov 11, 2025

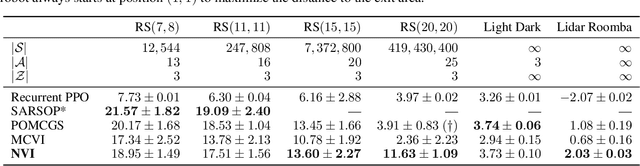

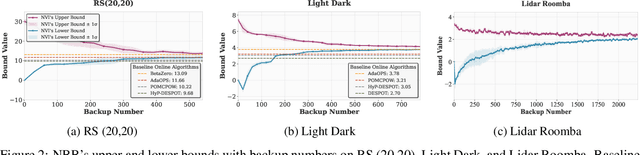

Abstract:The value function of a POMDP exhibits the piecewise-linear-convex (PWLC) property and can be represented as a finite set of hyperplanes, known as $α$-vectors. Most state-of-the-art POMDP solvers (offline planners) follow the point-based value iteration scheme, which performs Bellman backups on $α$-vectors at reachable belief points until convergence. However, since each $α$-vector is $|S|$-dimensional, these methods quickly become intractable for large-scale problems due to the prohibitive computational cost of Bellman backups. In this work, we demonstrate that the PWLC property allows a POMDP's value function to be alternatively represented as a finite set of neural networks. This insight enables a novel POMDP planning algorithm called \emph{Neural Value Iteration}, which combines the generalization capability of neural networks with the classical value iteration framework. Our approach achieves near-optimal solutions even in extremely large POMDPs that are intractable for existing offline solvers.

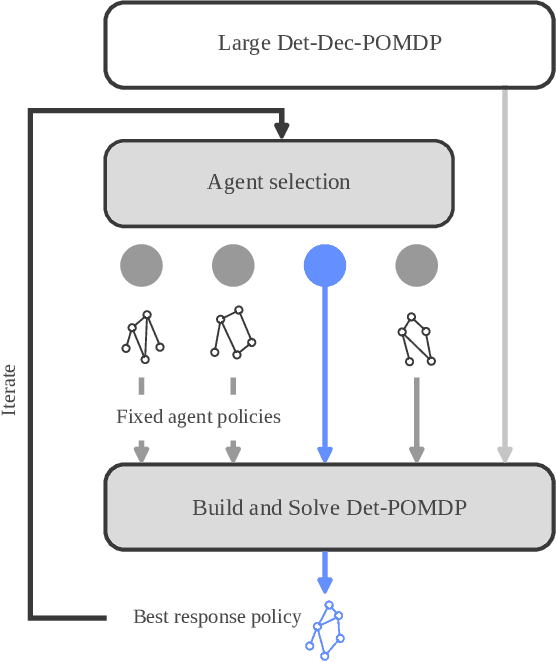

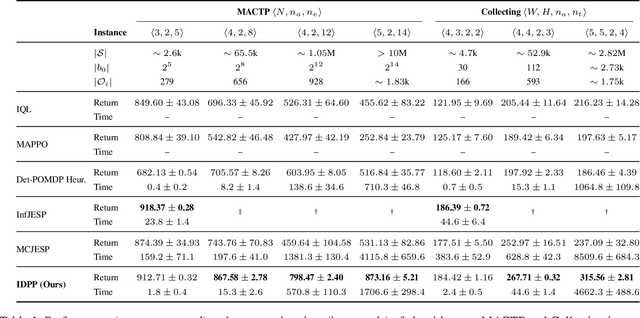

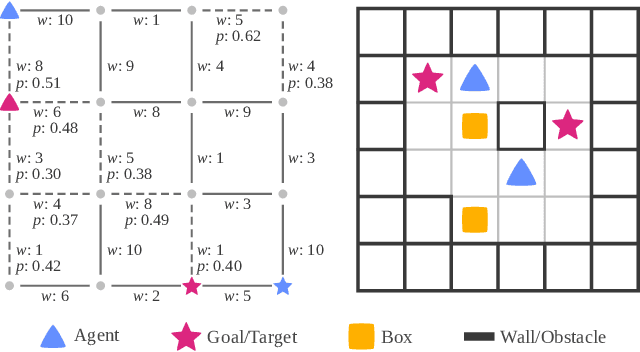

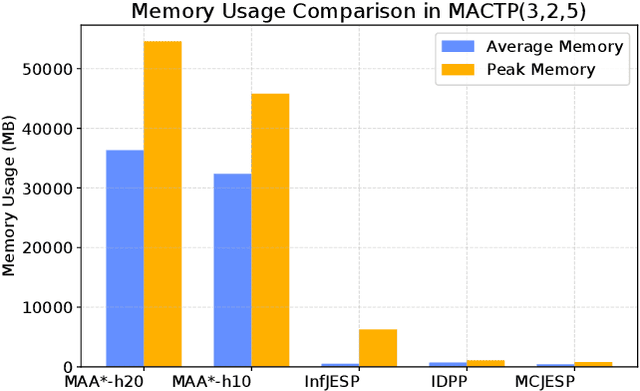

Scalable Solution Methods for Dec-POMDPs with Deterministic Dynamics

Aug 29, 2025

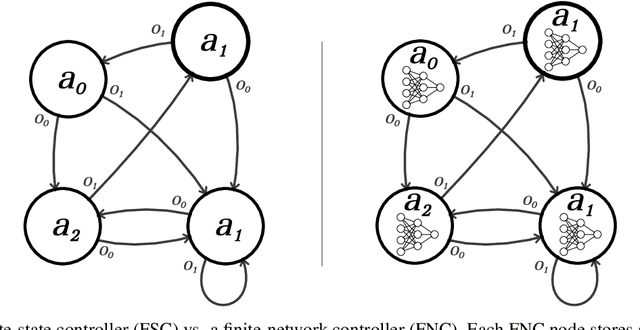

Abstract:Many high-level multi-agent planning problems, including multi-robot navigation and path planning, can be effectively modeled using deterministic actions and observations. In this work, we focus on such domains and introduce the class of Deterministic Decentralized POMDPs (Det-Dec-POMDPs). This is a subclass of Dec-POMDPs characterized by deterministic transitions and observations conditioned on the state and joint actions. We then propose a practical solver called Iterative Deterministic POMDP Planning (IDPP). This method builds on the classic Joint Equilibrium Search for Policies framework and is specifically optimized to handle large-scale Det-Dec-POMDPs that current Dec-POMDP solvers are unable to address efficiently.

Partially Observable Monte-Carlo Graph Search

Jul 28, 2025

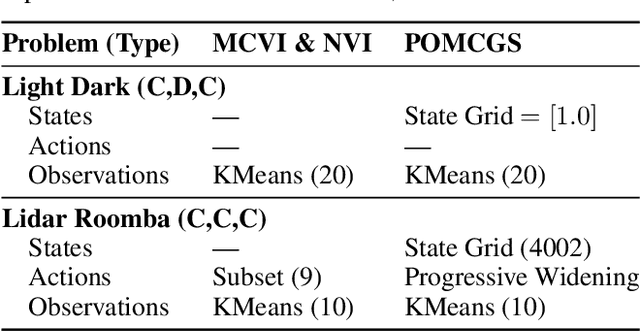

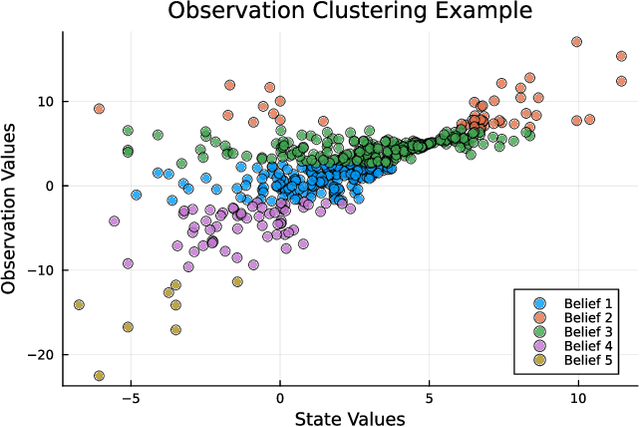

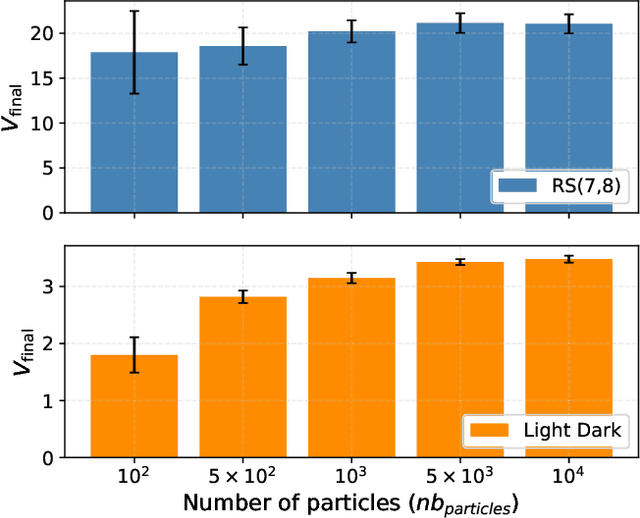

Abstract:Currently, large partially observable Markov decision processes (POMDPs) are often solved by sampling-based online methods which interleave planning and execution phases. However, a pre-computed offline policy is more desirable in POMDP applications with time or energy constraints. But previous offline algorithms are not able to scale up to large POMDPs. In this article, we propose a new sampling-based algorithm, the partially observable Monte-Carlo graph search (POMCGS) to solve large POMDPs offline. Different from many online POMDP methods, which progressively develop a tree while performing (Monte-Carlo) simulations, POMCGS folds this search tree on the fly to construct a policy graph, so that computations can be drastically reduced, and users can analyze and validate the policy prior to embedding and executing it. Moreover, POMCGS, together with action progressive widening and observation clustering methods provided in this article, is able to address certain continuous POMDPs. Through experiments, we demonstrate that POMCGS can generate policies on the most challenging POMDPs, which cannot be computed by previous offline algorithms, and these policies' values are competitive compared with the state-of-the-art online POMDP algorithms.

AutoInspect: Towards Long-Term Autonomous Industrial Inspection

Apr 19, 2024Abstract:We give an overview of AutoInspect, a ROS-based software system for robust and extensible mission-level autonomy. Over the past three years AutoInspect has been deployed in a variety of environments, including at a mine, a chemical plant, a mock oil rig, decommissioned nuclear power plants, and a fusion reactor for durations ranging from hours to weeks. The system combines robust mapping and localisation with graph-based autonomous navigation, mission execution, and scheduling to achieve a complete autonomous inspection system. The time from arrival at a new site to autonomous mission execution can be under an hour. It is deployed on a Boston Dynamics Spot robot using a custom sensing and compute payload called Frontier. In this work we go into detail of the system's performance in two long-term deployments of 49 days at a robotics test facility, and 35 days at the Joint European Torus (JET) fusion reactor in Oxfordshire, UK.

Sim-to-Real Deep Reinforcement Learning with Manipulators for Pick-and-place

Sep 17, 2023Abstract:When transferring a Deep Reinforcement Learning model from simulation to the real world, the performance could be unsatisfactory since the simulation cannot imitate the real world well in many circumstances. This results in a long period of fine-tuning in the real world. This paper proposes a self-supervised vision-based DRL method that allows robots to pick and place objects effectively and efficiently when directly transferring a training model from simulation to the real world. A height-sensitive action policy is specially designed for the proposed method to deal with crowded and stacked objects in challenging environments. The training model with the proposed approach can be applied directly to a real suction task without any fine-tuning from the real world while maintaining a high suction success rate. It is also validated that our model can be deployed to suction novel objects in a real experiment with a suction success rate of 90\% without any real-world fine-tuning. The experimental video is available at: https://youtu.be/jSTC-EGsoFA.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge