Reem Khir

Optimization-based Learning for Dynamic Load Planning in Trucking Service Networks

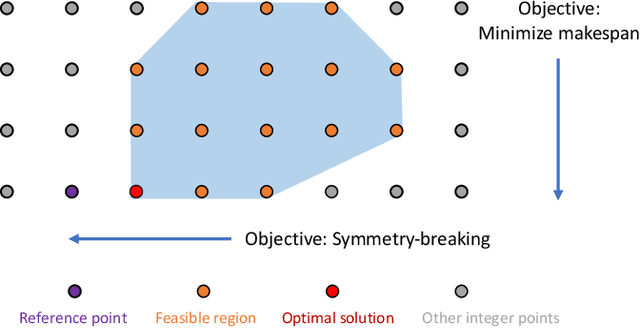

Jul 08, 2023Abstract:The load planning problem is a critical challenge in service network design for parcel carriers: it decides how many trailers (or loads) to assign for dispatch over time between pairs of terminals. Another key challenge is to determine a flow plan, which specifies how parcel volumes are assigned to planned loads. This paper considers the Dynamic Load Planning Problem (DLPP) that considers both flow and load planning challenges jointly to adjust loads and flows as the demand forecast changes over time before the day of operations. The paper aims at developing a decision-support tool to inform planners making these decisions at terminals across the network. The paper formulates the DLPP as a MIP and shows that it admits a large number of symmetries in a network where each commodity can be routed through primary and alternate paths. As a result, an optimization solver may return fundamentally different solutions to closely related problems, confusing planners and reducing trust in optimization. To remedy this limitation, the paper proposes a Goal-Directed Optimization that eliminates those symmetries by generating optimal solutions staying close to a reference plan. The paper also proposes an optimization proxy to address the computational challenges of the optimization models. The proxy combines a machine learning model and a feasibility restoration model and finds solutions that satisfy real-time constraints imposed by planners-in-the-loop. An extensive computational study on industrial instances shows that the optimization proxy is around 10 times faster than the commercial solver in obtaining the same quality solutions and orders of magnitude faster for generating solutions that are consistent with each other. The proposed approach also demonstrates the benefits of the DLPP for load consolidation, and the significant savings obtained from combining machine learning and optimization.

Two-Stage Learning For the Flexible Job Shop Scheduling Problem

Jan 23, 2023

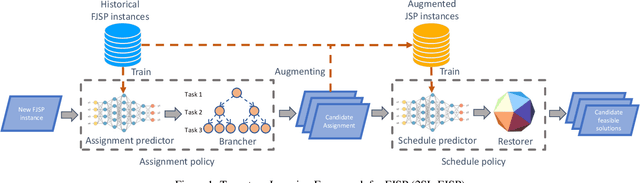

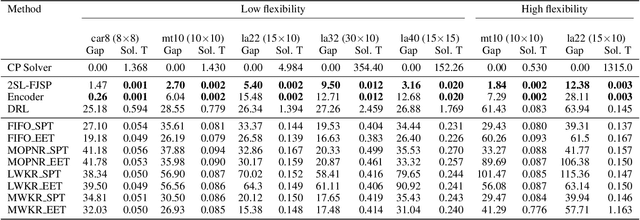

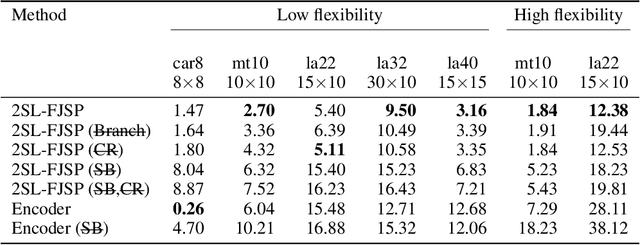

Abstract:The Flexible Job-shop Scheduling Problem (FJSP) is an important combinatorial optimization problem that arises in manufacturing and service settings. FJSP is composed of two subproblems, an assignment problem that assigns tasks to machines, and a scheduling problem that determines the starting times of tasks on their chosen machines. Solving FJSP instances of realistic size and composition is an ongoing challenge even under simplified, deterministic assumptions. Motivated by the inevitable randomness and uncertainties in supply chains, manufacturing, and service operations, this paper investigates the potential of using a deep learning framework to generate fast and accurate approximations for FJSP. In particular, this paper proposes a two-stage learning framework 2SLFJSP that explicitly models the hierarchical nature of FJSP decisions, uses a confidence-aware branching scheme to generate appropriate instances for the scheduling stage from the assignment predictions and leverages a novel symmetry-breaking formulation to improve learnability. 2SL-FJSP is evaluated on instances from the FJSP benchmark library. Results show that 2SL-FJSP can generate high-quality solutions in milliseconds, outperforming a state-of-the-art reinforcement learning approach recently proposed in the literature, and other heuristics commonly used in practice.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge