Pouya P. Niaz

Efficient and Safe Contact-rich pHRI via Subtask Detection and Motion Estimation using Deep Learning

Jul 19, 2024

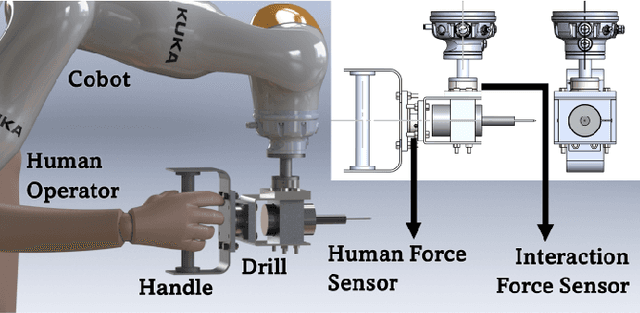

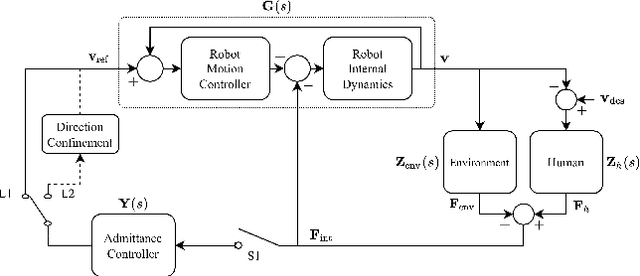

Abstract:This paper proposes an adaptive admittance controller for improving efficiency and safety in physical human-robot interaction (pHRI) tasks in small-batch manufacturing that involve contact with stiff environments, such as drilling, polishing, cutting, etc. We aim to minimize human effort and task completion time while maximizing precision and stability during the contact of the machine tool attached to the robot's end-effector with the workpiece. To this end, a two-layered learning-based human intention recognition mechanism is proposed, utilizing only the kinematic and kinetic data from the robot and two force sensors. A ``subtask detector" recognizes the human intent by estimating which phase of the task is being performed, e.g., \textit{Idle}, \textit{Tool-Attachment}, \textit{Driving}, and \textit{Contact}. Simultaneously, a ``motion estimator" continuously quantifies intent more precisely during the \textit{Driving} to predict when \textit{Contact} will begin. The controller is adapted online according to the subtask while allowing early adaptation before the \textit{Contact} to maximize precision and safety and prevent potential instabilities. Three sets of pHRI experiments were performed with multiple subjects under various conditions. Spring compression experiments were performed in virtual environments to train the data-driven models and validate the proposed adaptive system, and drilling experiments were performed in the physical world to test the proposed methods' efficacy in real-life scenarios. Experimental results show subtask classification accuracy of 84\% and motion estimation R\textsuperscript{2} score of 0.96. Furthermore, 57\% lower human effort was achieved during \textit{Driving} as well as 53\% lower oscillation amplitude at \textit{Contact} as a result of the proposed system.

Robot-Assisted Drilling on Curved Surfaces with Haptic Guidance under Adaptive Admittance Control

Jul 28, 2022

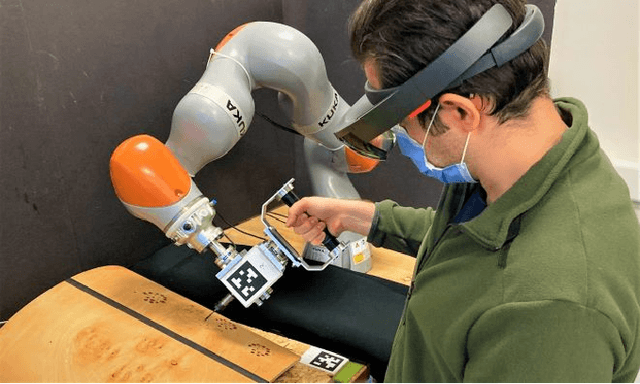

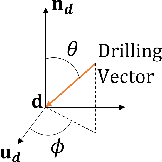

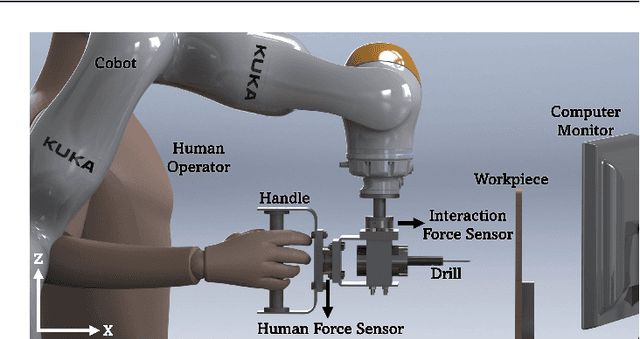

Abstract:Drilling a hole on a curved surface with a desired angle is prone to failure when done manually, due to the difficulties in drill alignment and also inherent instabilities of the task, potentially causing injury and fatigue to the workers. On the other hand, it can be impractical to fully automate such a task in real manufacturing environments because the parts arriving at an assembly line can have various complex shapes where drill point locations are not easily accessible, making automated path planning difficult. In this work, an adaptive admittance controller with 6 degrees of freedom is developed and deployed on a KUKA LBR iiwa 7 cobot such that the operator is able to manipulate a drill mounted on the robot with one hand comfortably and open holes on a curved surface with haptic guidance of the cobot and visual guidance provided through an AR interface. Real-time adaptation of the admittance damping provides more transparency when driving the robot in free space while ensuring stability during drilling. After the user brings the drill sufficiently close to the drill target and roughly aligns to the desired drilling angle, the haptic guidance module fine tunes the alignment first and then constrains the user movement to the drilling axis only, after which the operator simply pushes the drill into the workpiece with minimal effort. Two sets of experiments were conducted to investigate the potential benefits of the haptic guidance module quantitatively (Experiment I) and also the practical value of the proposed pHRI system for real manufacturing settings based on the subjective opinion of the participants (Experiment II).

An adaptive admittance controller for collaborative drilling with a robot based on subtask classification via deep learning

May 31, 2022

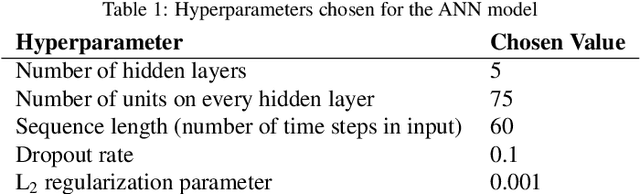

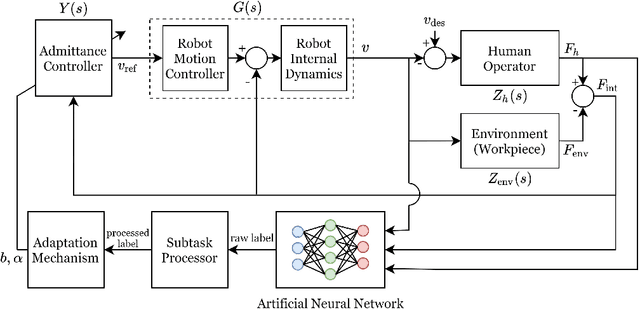

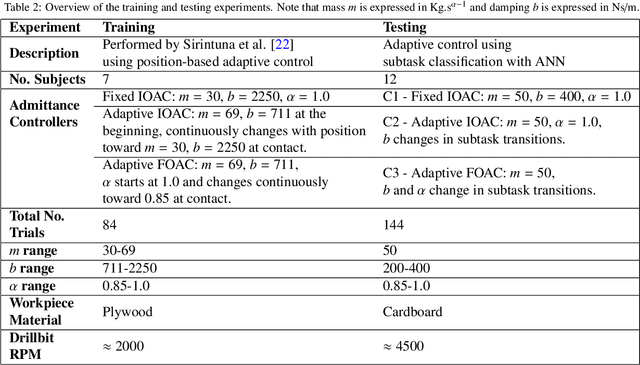

Abstract:In this paper, we propose a supervised learning approach based on an Artificial Neural Network (ANN) model for real-time classification of subtasks in a physical human-robot interaction (pHRI) task involving contact with a stiff environment. In this regard, we consider three subtasks for a given pHRI task: Idle, Driving, and Contact. Based on this classification, the parameters of an admittance controller that regulates the interaction between human and robot are adjusted adaptively in real time to make the robot more transparent to the operator (i.e. less resistant) during the Driving phase and more stable during the Contact phase. The Idle phase is primarily used to detect the initiation of task. Experimental results have shown that the ANN model can learn to detect the subtasks under different admittance controller conditions with an accuracy of 98% for 12 participants. Finally, we show that the admittance adaptation based on the proposed subtask classifier leads to 20% lower human effort (i.e. higher transparency) in the Driving phase and 25% lower oscillation amplitude (i.e. higher stability) during drilling in the Contact phase compared to an admittance controller with fixed parameters.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge