Peter Wriggers

Model-data-driven constitutive responses: application to a multiscale computational framework

Apr 06, 2021

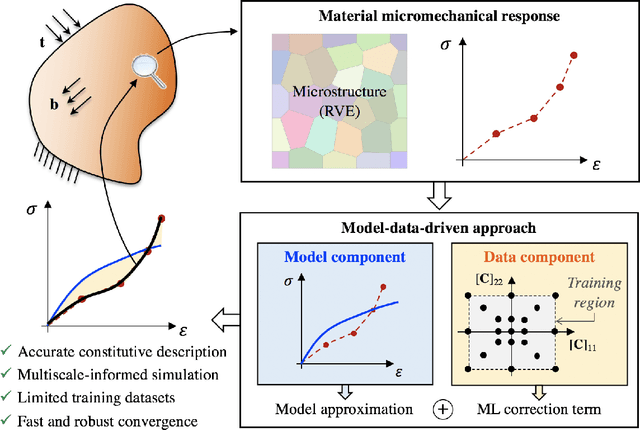

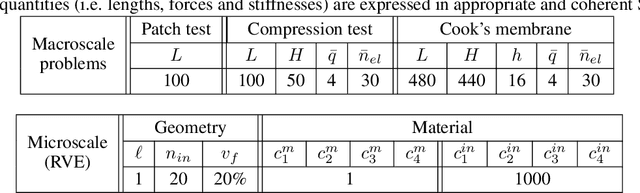

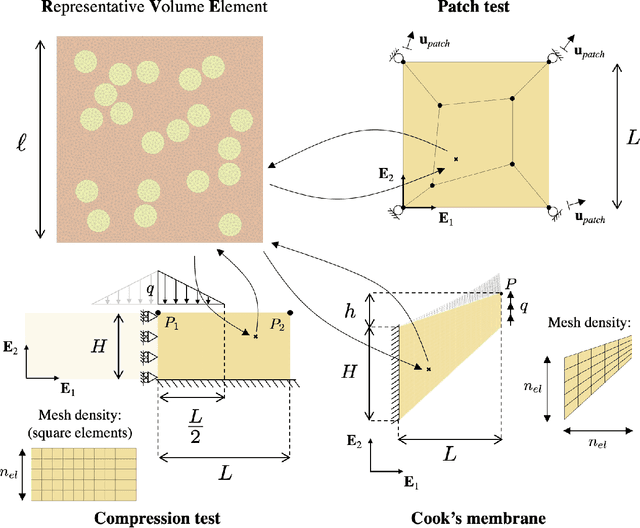

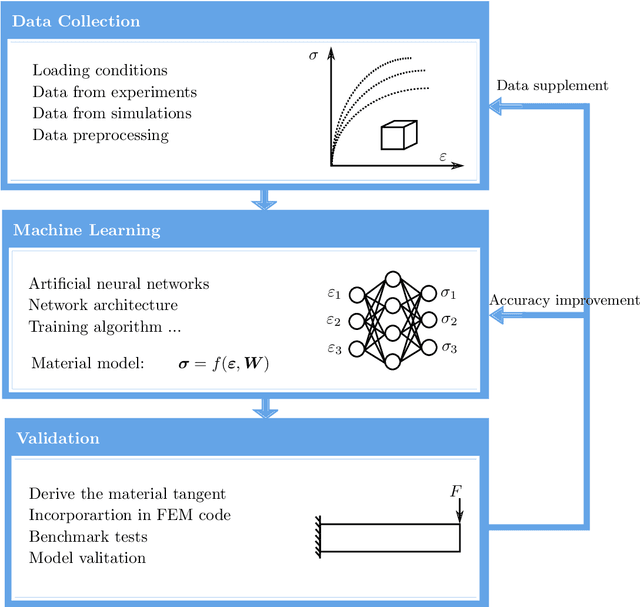

Abstract:Computational multiscale methods for analyzing and deriving constitutive responses have been used as a tool in engineering problems because of their ability to combine information at different length scales. However, their application in a nonlinear framework can be limited by high computational costs, numerical difficulties, and/or inaccuracies. In this paper, a hybrid methodology is presented which combines classical constitutive laws (model-based), a data-driven correction component, and computational multiscale approaches. A model-based material representation is locally improved with data from lower scales obtained by means of a nonlinear numerical homogenization procedure leading to a model-data-driven approach. Therefore, macroscale simulations explicitly incorporate the true microscale response, maintaining the same level of accuracy that would be obtained with online micro-macro simulations but with a computational cost comparable to classical model-driven approaches. In the proposed approach, both model and data play a fundamental role allowing for the synergistic integration between a physics-based response and a machine learning black-box. Numerical applications are implemented in two dimensions for different tests investigating both material and structural responses in large deformation.

A machine learning based plasticity model using proper orthogonal decomposition

Jan 07, 2020

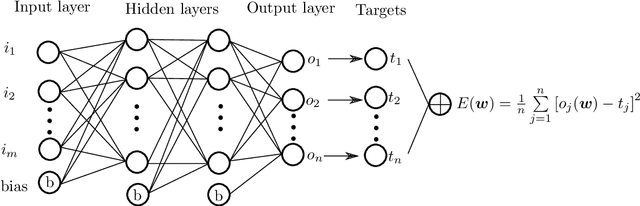

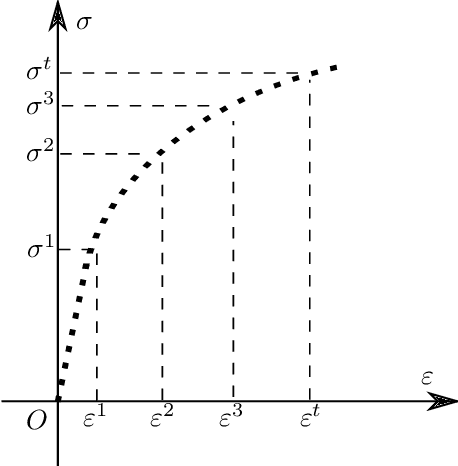

Abstract:Data-driven material models have many advantages over classical numerical approaches, such as the direct utilization of experimental data and the possibility to improve performance of predictions when additional data is available. One approach to develop a data-driven material model is to use machine learning tools. These can be trained offline to fit an observed material behaviour and then be applied in online applications. However, learning and predicting history dependent material models, such as plasticity, is still challenging. In this work, a machine learning based material modelling framework is proposed for both elasticity and plasticity. The machine learning based hyperelasticity model is developed with the Feed forward Neural Network (FNN) directly whereas the machine learning based plasticity model is developed by using of a novel method called Proper Orthogonal Decomposition Feed forward Neural Network (PODFNN). In order to account for the loading history, the accumulated absolute strain is proposed to be the history variable of the plasticity model. Additionally, the strain-stress sequence data for plasticity is collected from different loading-unloading paths based on the concept of sequence for plasticity. By means of the POD, the multi-dimensional stress sequence is decoupled leading to independent one dimensional coefficient sequences. In this case, the neural network with multiple output is replaced by multiple independent neural networks each possessing a one-dimensional output, which leads to less training time and better training performance. To apply the machine learning based material model in finite element analysis, the tangent matrix is derived by the automatic symbolic differentiation tool AceGen. The effectiveness and generalization of the presented models are investigated by a series of numerical examples using both 2D and 3D finite element analysis.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge