Michael T. Kidd

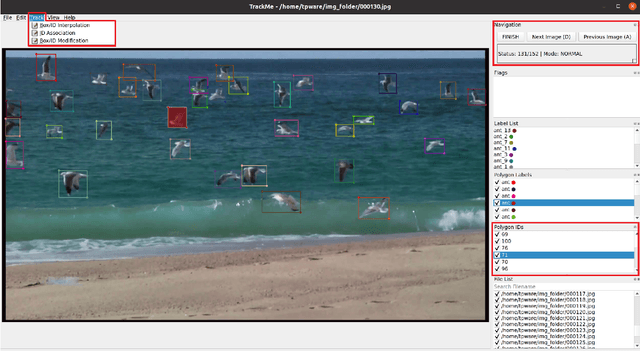

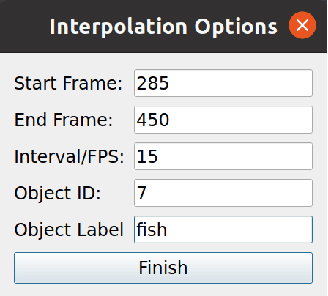

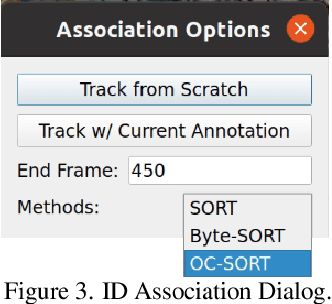

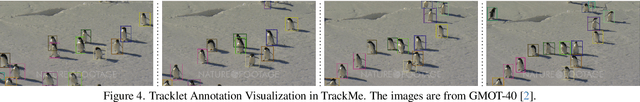

TrackMe:A Simple and Effective Multiple Object Tracking Annotation Tool

Oct 20, 2024

Abstract:Object tracking, especially animal tracking, is one of the key topics that attract a lot of attention due to its benefits of animal behavior understanding and monitoring. Recent state-of-the-art tracking methods are founded on deep learning architectures for object detection, appearance feature extraction and track association. Despite the good tracking performance, these methods are trained and evaluated on common objects such as human and cars. To perform on the animal, there is a need to create large datasets of different types in multiple conditions. The dataset construction comprises of data collection and data annotation. In this work, we put more focus on the latter task. Particularly, we renovate the well-known tool, LabelMe, so as to assist common user with or without in-depth knowledge about computer science to annotate the data with less effort. The new tool named as TrackMe inherits the simplicity, high compatibility with varied systems, minimal hardware requirement and convenient feature utilization from the predecessor. TrackMe is an upgraded version with essential features for multiple object tracking annotation.

Facial Chick Sexing: An Automated Chick Sexing System From Chick Facial Image

Oct 11, 2024

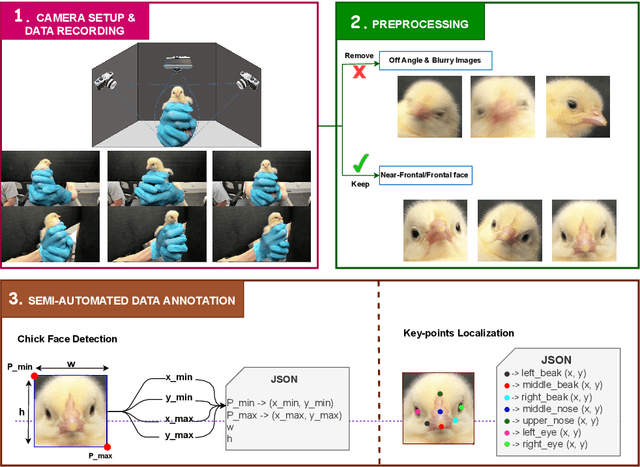

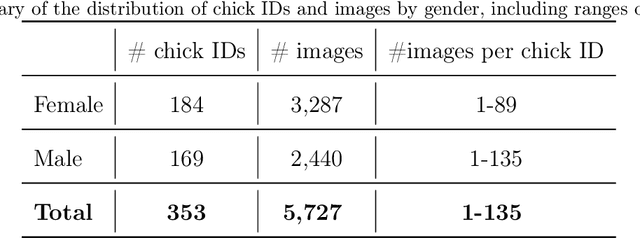

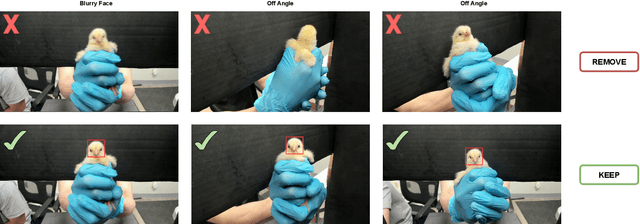

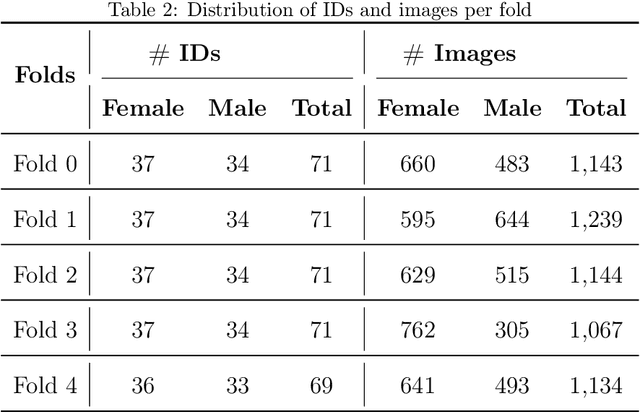

Abstract:Chick sexing, the process of determining the gender of day-old chicks, is a critical task in the poultry industry due to the distinct roles that each gender plays in production. While effective traditional methods achieve high accuracy, color, and wing feather sexing is exclusive to specific breeds, and vent sexing is invasive and requires trained experts. To address these challenges, we propose a novel approach inspired by facial gender classification techniques in humans: facial chick sexing. This new method does not require expert knowledge and aims to reduce training time while enhancing animal welfare by minimizing chick manipulation. We develop a comprehensive system for training and inference that includes data collection, facial and keypoint detection, facial alignment, and classification. We evaluate our model on two sets of images: Cropped Full Face and Cropped Middle Face, both of which maintain essential facial features of the chick for further analysis. Our experiment demonstrates the promising viability, with a final accuracy of 81.89%, of this approach for future practices in chick sexing by making them more universally applicable.

CarcassFormer: An End-to-end Transformer-based Framework for Simultaneous Localization, Segmentation and Classification of Poultry Carcass Defect

Apr 17, 2024Abstract:In the food industry, assessing the quality of poultry carcasses during processing is a crucial step. This study proposes an effective approach for automating the assessment of carcass quality without requiring skilled labor or inspector involvement. The proposed system is based on machine learning (ML) and computer vision (CV) techniques, enabling automated defect detection and carcass quality assessment. To this end, an end-to-end framework called CarcassFormer is introduced. It is built upon a Transformer-based architecture designed to effectively extract visual representations while simultaneously detecting, segmenting, and classifying poultry carcass defects. Our proposed framework is capable of analyzing imperfections resulting from production and transport welfare issues, as well as processing plant stunner, scalder, picker, and other equipment malfunctions. To benchmark the framework, a dataset of 7,321 images was initially acquired, which contained both single and multiple carcasses per image. In this study, the performance of the CarcassFormer system is compared with other state-of-the-art (SOTA) approaches for both classification, detection, and segmentation tasks. Through extensive quantitative experiments, our framework consistently outperforms existing methods, demonstrating remarkable improvements across various evaluation metrics such as AP, AP@50, and AP@75. Furthermore, the qualitative results highlight the strengths of CarcassFormer in capturing fine details, including feathers, and accurately localizing and segmenting carcasses with high precision. To facilitate further research and collaboration, the pre-trained model and source code of CarcassFormer is available for research purposes at: \url{https://github.com/UARK-AICV/CarcassFormer}.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge