Melih C. Yesilli

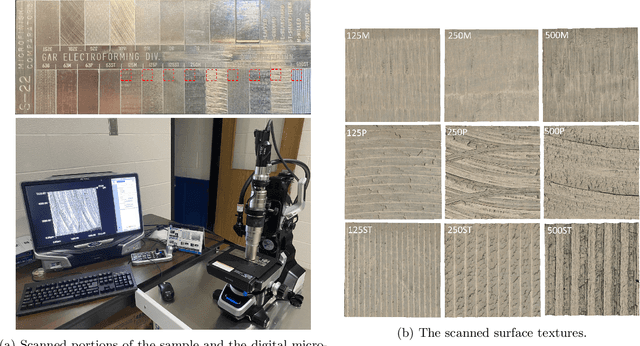

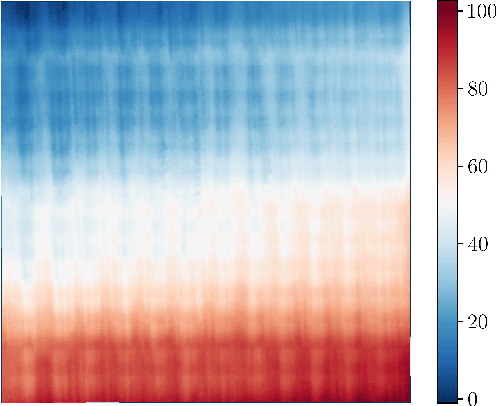

Automated Surface Texture Analysis via Discrete Cosine Transform and Discrete Wavelet Transform

Apr 12, 2022

Abstract:Surface roughness and texture are critical to the functional performance of engineering components. The ability to analyze roughness and texture effectively and efficiently is much needed to ensure surface quality in many surface generation processes, such as machining, surface mechanical treatment, etc. Discrete Wavelet Transform (DWT) and Discrete Cosine Transform (DCT) are two commonly used signal decomposition tools for surface roughness and texture analysis. Both methods require selecting a threshold to decompose a given surface into its three main components: form, waviness, and roughness. However, although DWT and DCT are part of the ISO surface finish standards, there exists no systematic guidance on how to compute these thresholds, and they are often manually selected on case by case basis. This makes utilizing these methods for studying surfaces dependent on the user's judgment and limits their automation potential. Therefore, we present two automatic threshold selection algorithms based on information theory and signal energy. We use machine learning to validate the success of our algorithms both using simulated surfaces as well as digital microscopy images of machined surfaces. Specifically, we generate feature vectors for each surface area or profile and apply supervised classification. Comparing our results with the heuristic threshold selection approach shows good agreement with mean accuracies as high as 95\%. We also compare our results with Gaussian filtering (GF) and show that while GF results for areas can yield slightly higher accuracies, our results outperform GF for surface profiles. We further show that our automatic threshold selection has significant advantages in terms of computational time as evidenced by decreasing the number of mode computations by an order of magnitude compared to the heuristic thresholding for DCT.

Transfer Learning for Autonomous Chatter Detection in Machining

Apr 11, 2022

Abstract:Large-amplitude chatter vibrations are one of the most important phenomena in machining processes. It is often detrimental in cutting operations causing a poor surface finish and decreased tool life. Therefore, chatter detection using machine learning has been an active research area over the last decade. Three challenges can be identified in applying machine learning for chatter detection at large in industry: an insufficient understanding of the universality of chatter features across different processes, the need for automating feature extraction, and the existence of limited data for each specific workpiece-machine tool combination. These three challenges can be grouped under the umbrella of transfer learning. This paper studies automating chatter detection by evaluating transfer learning of prominent as well as novel chatter detection methods. We investigate chatter classification accuracy using a variety of features extracted from turning and milling experiments with different cutting configurations. The studied methods include Fast Fourier Transform (FFT), Power Spectral Density (PSD), the Auto-correlation Function (ACF), Wavelet Packet Transform (WPT), and Ensemble Empirical Mode Decomposition (EEMD). We also examine more recent approaches based on Topological Data Analysis (TDA) and similarity measures of time series based on Discrete Time Warping (DTW). We evaluate the transfer learning potential of each approach by training and testing both within and across the turning and milling data sets. Our results show that carefully chosen time-frequency features can lead to high classification accuracies albeit at the cost of requiring manual pre-processing and the tagging of an expert user. On the other hand, we found that the TDA and DTW approaches can provide accuracies and F1 scores on par with the time-frequency methods without the need for manual preprocessing.

Data-driven and Automatic Surface Texture Analysis Using Persistent Homology

Oct 19, 2021

Abstract:Surface roughness plays an important role in analyzing engineering surfaces. It quantifies the surface topography and can be used to determine whether the resulting surface finish is acceptable or not. Nevertheless, while several existing tools and standards are available for computing surface roughness, these methods rely heavily on user input thus slowing down the analysis and increasing manufacturing costs. Therefore, fast and automatic determination of the roughness level is essential to avoid costs resulting from surfaces with unacceptable finish, and user-intensive analysis. In this study, we propose a Topological Data Analysis (TDA) based approach to classify the roughness level of synthetic surfaces using both their areal images and profiles. We utilize persistent homology from TDA to generate persistence diagrams that encapsulate information on the shape of the surface. We then obtain feature matrices for each surface or profile using Carlsson coordinates, persistence images, and template functions. We compare our results to two widely used methods in the literature: Fast Fourier Transform (FFT) and Gaussian filtering. The results show that our approach yields mean accuracies as high as 97%. We also show that, in contrast to existing surface analysis tools, our TDA-based approach is fully automatable and provides adaptive feature extraction.

On Transfer Learning of Traditional Frequency and Time Domain Features in Turning

Aug 28, 2020

Abstract:There has been an increasing interest in leveraging machine learning tools for chatter prediction and diagnosis in discrete manufacturing processes. Some of the most common features for studying chatter include traditional signal processing tools such as Fast Fourier Transform (FFT), Power Spectral Density (PSD), and the Auto-correlation Function (ACF). In this study, we use these tools in a supervised learning setting to identify chatter in accelerometer signals obtained from a turning experiment. The experiment is performed using four different tool overhang lengths with varying cutting speed and the depth of cut. We then examine the resulting signals and tag them as either chatter or chatter-free. The tagged signals are then used to train a classifier. The classification methods include the most common algorithms: Support Vector Machine (SVM), Logistic Regression (LR), Random Forest (RF), and Gradient Boost (GB). Our results show that features extracted from the Fourier spectrum are the most informative when training a classifier and testing on data from the same cutting configuration yielding accuracy as high as %96. However, the accuracy drops significantly when training and testing on two different configurations with different structural eigenfrequencies. Thus, we conclude that while these traditional features can be highly tuned to a certain process, their transfer learning ability is limited. We also compare our results against two other methods with rising popularity in the literature: Wavelet Packet Transform (WPT) and Ensemble Empirical Mode Decomposition (EEMD). The latter two methods, especially EEMD, show better transfer learning capabilities for our dataset.

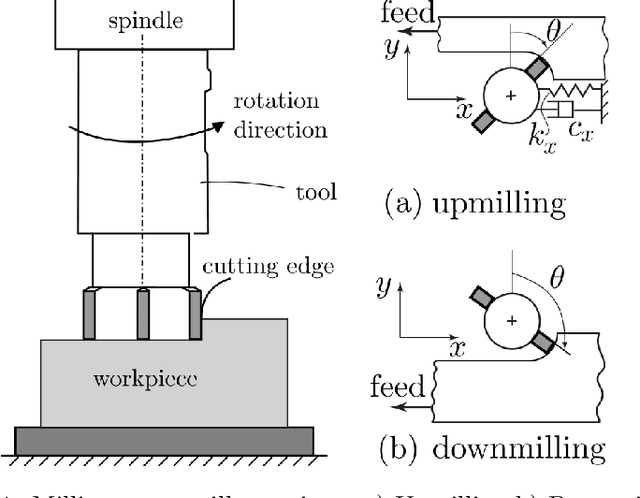

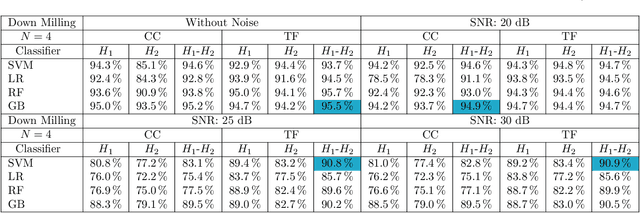

Chatter Diagnosis in Milling Using Supervised Learning and Topological Features Vector

Oct 27, 2019

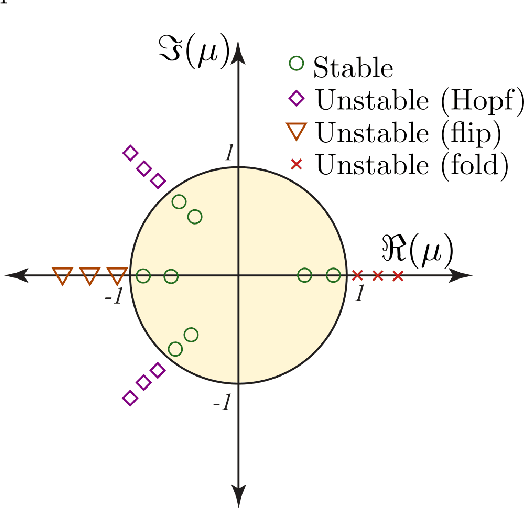

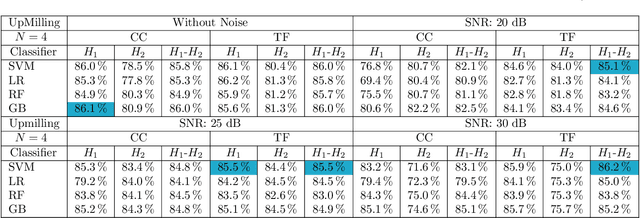

Abstract:Chatter detection has become a prominent subject of interest due to its effect on cutting tool life, surface finish and spindle of machine tool. Most of the existing methods in chatter detection literature are based on signal processing and signal decomposition. In this study, we use topological features of data simulating cutting tool vibrations, combined with four supervised machine learning algorithms to diagnose chatter in the milling process. Persistence diagrams, a method of representing topological features, are not easily used in the context of machine learning, so they must be transformed into a form that is more amenable. Specifically, we will focus on two different methods for featurizing persistence diagrams, Carlsson coordinates and template functions. In this paper, we provide classification results for simulated data from various cutting configurations, including upmilling and downmilling, in addition to the same data with some added noise. Our results show that Carlsson Coordinates and Template Functions yield accuracies as high as 96% and 95%, respectively. We also provide evidence that these topological methods are noise robust descriptors for chatter detection.

Chatter Detection in Turning Using Machine Learning and Similarity Measures of Time Series via Dynamic Time Warping

Aug 05, 2019

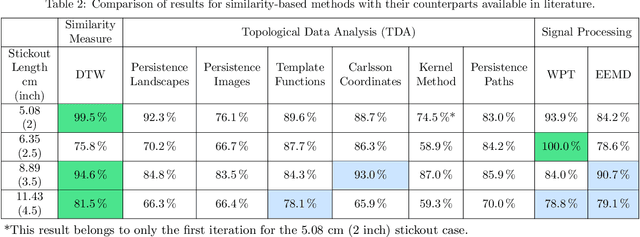

Abstract:Chatter detection from sensor signals has been an active field of research. While some success has been reported using several featurization tools and machine learning algorithms, existing methods have several drawbacks such as manual preprocessing and requiring a large data set. In this paper, we present an alternative approach for chatter detection based on K-Nearest Neighbor (kNN) algorithm for classification and the Dynamic Time Warping (DTW) as a time series similarity measure. The used time series are the acceleration signals acquired from the tool holder in a series of turning experiments. Our results, show that this approach achieves detection accuracies that in most cases outperform existing methods. We compare our results to the traditional methods based on Wavelet Packet Transform (WPT) and the Ensemble Empirical Mode Decomposition (EEMD), as well as to the more recent Topological Data Analysis (TDA) based approach. We show that in three out of four cutting configurations our DTW-based approach attains the highest average classification rate reaching in one case as high as 99% accuracy. Our approach does not require feature extraction, is capable of reusing a classifier across different cutting configurations, and it uses reasonably sized training sets. Although the resulting high accuracy in our approach is associated with high computational cost, this is specific to the DTW implementation that we used. Specifically, we highlight available, very fast DTW implementations that can even be implemented on small consumer electronics. Therefore, further code optimization and the significantly reduced computational effort during the implementation phase make our approach a viable option for in-process chatter detection.

Topological Feature Vectors for Chatter Detection in Turning Processes

May 27, 2019

Abstract:Machining processes are most accurately described using complex dynamical systems that include nonlinearities, time delays and stochastic effects. Due to the nature of these models as well as the practical challenges which include time-varying parameters, the transition from numerical/analytical modeling of machining to the analysis of real cutting signals remains challenging. Some studies have focused on studying the time series of cutting processes using machine learning algorithms with the goal of identifying and predicting undesirable vibrations during machining referred to as chatter. These tools typically decompose the signal using Wavelet Packet Transforms (WPT) or Ensemble Empirical Mode Decomposition (EEMD). However, these methods require a significant overhead in identifying the feature vectors before a classifier can be trained. In this study, we present an alternative approach based on featurizing the time series of the cutting process using its topological features. We utilize support vector machine classifier combined with feature vectors derived from persistence diagrams, a tool from persistent homology, to encode distinguishing characteristics based on embedding the time series as a point cloud using Takens embedding. We present the results for several choices of the topological feature vectors, and we compare our results to the WPT and EEMD methods using experimental time series from a turning cutting test. Our results show that in most cases combining the TDA-based features with a simple Support Vector Machine (SVM) yields accuracies that either exceed or are within the error bounds of their WPT and EEMD counterparts.

On Transfer Learning For Chatter Detection in Turning Using Wavelet Packet Transform and Empirical Mode Decomposition

May 03, 2019

Abstract:The increasing availability of sensor data at machine tools makes automatic chatter detection algorithms a trending topic in metal cutting. Two prominent and advanced methods for feature extraction via signal decomposition are Wavelet Packet Transform (WPT) and Ensemble Empirical Mode Decomposition (EEMD). We apply these two methods to time series acquired from an acceleration sensor at the tool holder of a lathe. Different turning experiments with varying dynamic behavior of the machine tool structure were performed. We compare the performance of these two methods with Support Vector Machine (SVM) classifier combined with Recursive Feature Elimination (RFE). We also show that the common WPT-based approach of choosing wavelet packets with the highest energy ratios as representative features for chatter does not always result in packets that enclose the chatter frequency, thus reducing the classification accuracy. Further, we test the transfer learning capability of each of these methods by training the classifier on one of the cutting configurations and then testing it on the other cases. It is found that when training and testing on data from the same cutting configuration both methods yield high accuracies reaching in one of the cases as high as 94% and 91%, respectively, for WPT and EEMD. However, EEMD is shown to outperform WPT in transfer learning applications with accuracy of up to 84%. Therefore, for systems where the movement of the cutting center leads to significant variations in the stiffness of the machine-tool system, we recommend using EEMD over WPT for training a classifier. This is because EEMD retains higher accuracy rates in comparison to WPT when the input data stream deviates from the data that was used to train the classifier.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge