Andreas Otto

Chatter Detection in Turning Using Machine Learning and Similarity Measures of Time Series via Dynamic Time Warping

Aug 05, 2019

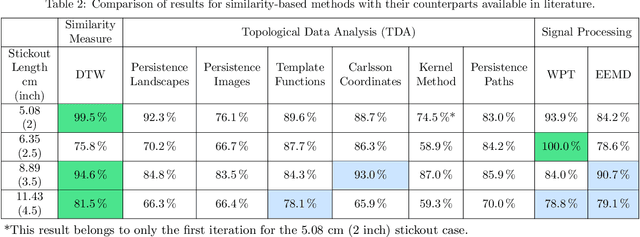

Abstract:Chatter detection from sensor signals has been an active field of research. While some success has been reported using several featurization tools and machine learning algorithms, existing methods have several drawbacks such as manual preprocessing and requiring a large data set. In this paper, we present an alternative approach for chatter detection based on K-Nearest Neighbor (kNN) algorithm for classification and the Dynamic Time Warping (DTW) as a time series similarity measure. The used time series are the acceleration signals acquired from the tool holder in a series of turning experiments. Our results, show that this approach achieves detection accuracies that in most cases outperform existing methods. We compare our results to the traditional methods based on Wavelet Packet Transform (WPT) and the Ensemble Empirical Mode Decomposition (EEMD), as well as to the more recent Topological Data Analysis (TDA) based approach. We show that in three out of four cutting configurations our DTW-based approach attains the highest average classification rate reaching in one case as high as 99% accuracy. Our approach does not require feature extraction, is capable of reusing a classifier across different cutting configurations, and it uses reasonably sized training sets. Although the resulting high accuracy in our approach is associated with high computational cost, this is specific to the DTW implementation that we used. Specifically, we highlight available, very fast DTW implementations that can even be implemented on small consumer electronics. Therefore, further code optimization and the significantly reduced computational effort during the implementation phase make our approach a viable option for in-process chatter detection.

Topological Feature Vectors for Chatter Detection in Turning Processes

May 27, 2019

Abstract:Machining processes are most accurately described using complex dynamical systems that include nonlinearities, time delays and stochastic effects. Due to the nature of these models as well as the practical challenges which include time-varying parameters, the transition from numerical/analytical modeling of machining to the analysis of real cutting signals remains challenging. Some studies have focused on studying the time series of cutting processes using machine learning algorithms with the goal of identifying and predicting undesirable vibrations during machining referred to as chatter. These tools typically decompose the signal using Wavelet Packet Transforms (WPT) or Ensemble Empirical Mode Decomposition (EEMD). However, these methods require a significant overhead in identifying the feature vectors before a classifier can be trained. In this study, we present an alternative approach based on featurizing the time series of the cutting process using its topological features. We utilize support vector machine classifier combined with feature vectors derived from persistence diagrams, a tool from persistent homology, to encode distinguishing characteristics based on embedding the time series as a point cloud using Takens embedding. We present the results for several choices of the topological feature vectors, and we compare our results to the WPT and EEMD methods using experimental time series from a turning cutting test. Our results show that in most cases combining the TDA-based features with a simple Support Vector Machine (SVM) yields accuracies that either exceed or are within the error bounds of their WPT and EEMD counterparts.

On Transfer Learning For Chatter Detection in Turning Using Wavelet Packet Transform and Empirical Mode Decomposition

May 03, 2019

Abstract:The increasing availability of sensor data at machine tools makes automatic chatter detection algorithms a trending topic in metal cutting. Two prominent and advanced methods for feature extraction via signal decomposition are Wavelet Packet Transform (WPT) and Ensemble Empirical Mode Decomposition (EEMD). We apply these two methods to time series acquired from an acceleration sensor at the tool holder of a lathe. Different turning experiments with varying dynamic behavior of the machine tool structure were performed. We compare the performance of these two methods with Support Vector Machine (SVM) classifier combined with Recursive Feature Elimination (RFE). We also show that the common WPT-based approach of choosing wavelet packets with the highest energy ratios as representative features for chatter does not always result in packets that enclose the chatter frequency, thus reducing the classification accuracy. Further, we test the transfer learning capability of each of these methods by training the classifier on one of the cutting configurations and then testing it on the other cases. It is found that when training and testing on data from the same cutting configuration both methods yield high accuracies reaching in one of the cases as high as 94% and 91%, respectively, for WPT and EEMD. However, EEMD is shown to outperform WPT in transfer learning applications with accuracy of up to 84%. Therefore, for systems where the movement of the cutting center leads to significant variations in the stiffness of the machine-tool system, we recommend using EEMD over WPT for training a classifier. This is because EEMD retains higher accuracy rates in comparison to WPT when the input data stream deviates from the data that was used to train the classifier.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge