Max Yi Ren

Microstructure Representation and Reconstruction of Heterogeneous Materials via Deep Belief Network for Computational Material Design

Apr 28, 2017

Abstract:Integrated Computational Materials Engineering (ICME) aims to accelerate optimal design of complex material systems by integrating material science and design automation. For tractable ICME, it is required that (1) a structural feature space be identified to allow reconstruction of new designs, and (2) the reconstruction process be property-preserving. The majority of existing structural presentation schemes rely on the designer's understanding of specific material systems to identify geometric and statistical features, which could be biased and insufficient for reconstructing physically meaningful microstructures of complex material systems. In this paper, we develop a feature learning mechanism based on convolutional deep belief network to automate a two-way conversion between microstructures and their lower-dimensional feature representations, and to achieves a 1000-fold dimension reduction from the microstructure space. The proposed model is applied to a wide spectrum of heterogeneous material systems with distinct microstructural features including Ti-6Al-4V alloy, Pb63-Sn37 alloy, Fontainebleau sandstone, and Spherical colloids, to produce material reconstructions that are close to the original samples with respect to 2-point correlation functions and mean critical fracture strength. This capability is not achieved by existing synthesis methods that rely on the Markovian assumption of material microstructures.

Learning an Optimization Algorithm through Human Design Iterations

Apr 26, 2017

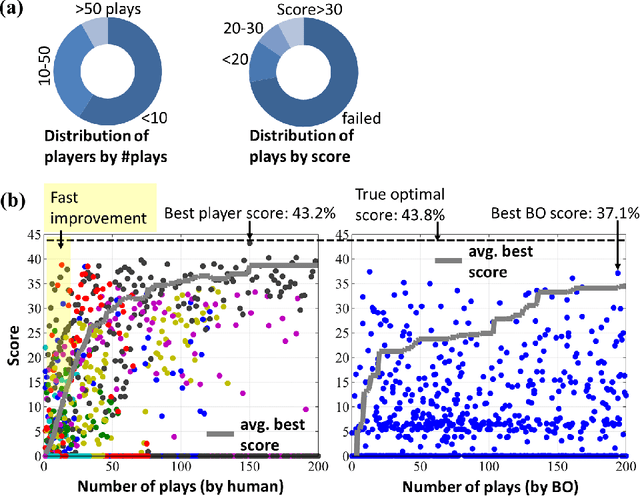

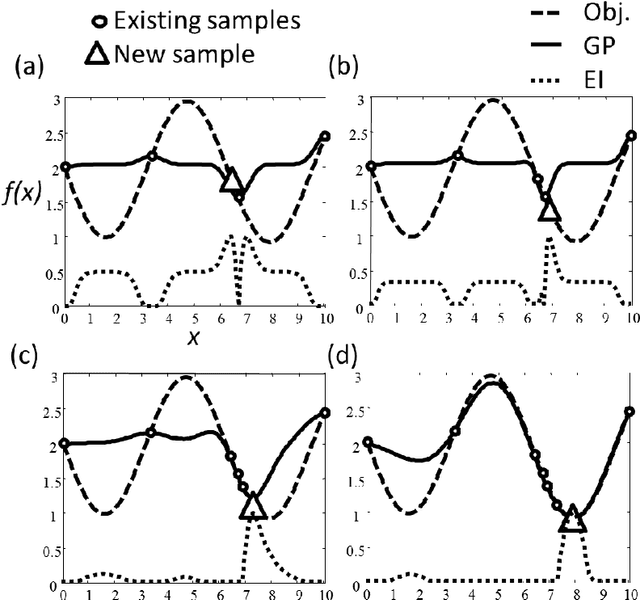

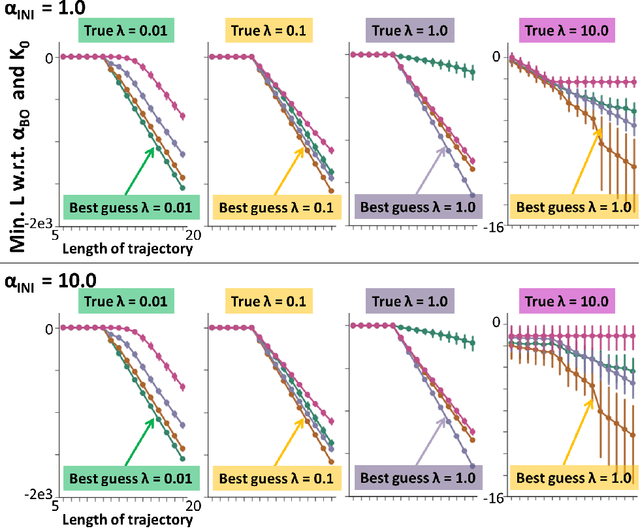

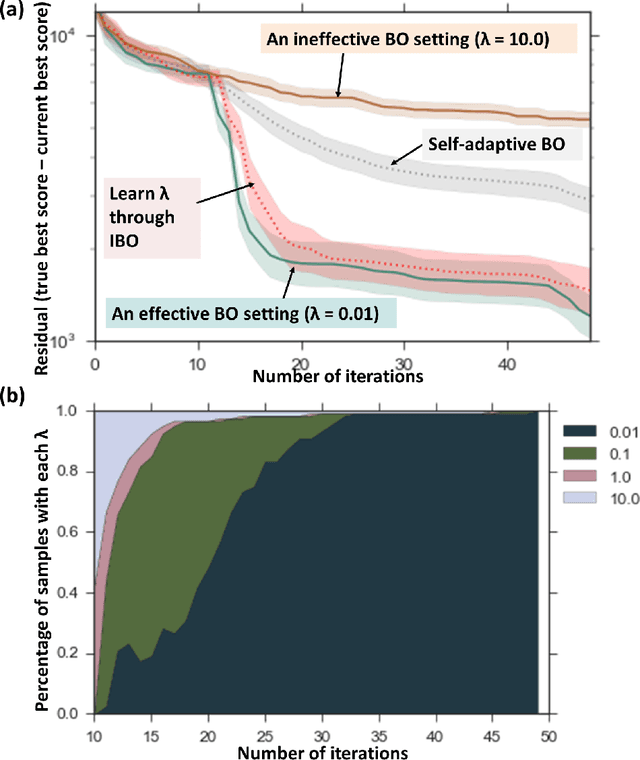

Abstract:Solving optimal design problems through crowdsourcing faces a dilemma: On one hand, human beings have been shown to be more effective than algorithms at searching for good solutions of certain real-world problems with high-dimensional or discrete solution spaces; on the other hand, the cost of setting up crowdsourcing environments, the uncertainty in the crowd's domain-specific competence, and the lack of commitment of the crowd, all contribute to the lack of real-world application of design crowdsourcing. We are thus motivated to investigate a solution-searching mechanism where an optimization algorithm is tuned based on human demonstrations on solution searching, so that the search can be continued after human participants abandon the problem. To do so, we model the iterative search process as a Bayesian Optimization (BO) algorithm, and propose an inverse BO (IBO) algorithm to find the maximum likelihood estimators of the BO parameters based on human solutions. We show through a vehicle design and control problem that the search performance of BO can be improved by recovering its parameters based on an effective human search. Thus, IBO has the potential to improve the success rate of design crowdsourcing activities, by requiring only good search strategies instead of good solutions from the crowd.

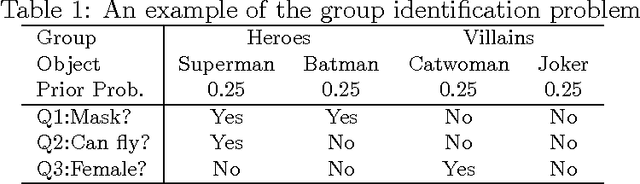

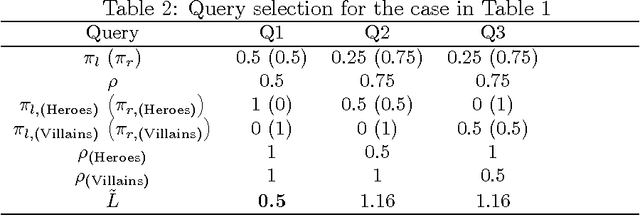

Adaptive Questionnaires for Direct Identification of Optimal Product Design

Jan 05, 2017

Abstract:We consider the problem of identifying the most profitable product design from a finite set of candidates under unknown consumer preference. A standard approach to this problem follows a two-step strategy: First, estimate the preference of the consumer population, represented as a point in part-worth space, using an adaptive discrete-choice questionnaire. Second, integrate the estimated part-worth vector with engineering feasibility and cost models to determine the optimal design. In this work, we (1) demonstrate that accurate preference estimation is neither necessary nor sufficient for identifying the optimal design, (2) introduce a novel adaptive questionnaire that leverages knowledge about engineering feasibility and manufacturing costs to directly determine the optimal design, and (3) interpret product design in terms of a nonlinear segmentation of part-worth space, and use this interpretation to illuminate the intrinsic difficulty of optimal design in the presence of noisy questionnaire responses. We establish the superiority of the proposed approach using a well-documented optimal product design task. This study demonstrates how the identification of optimal product design can be accelerated by integrating marketing and manufacturing knowledge into the adaptive questionnaire.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge